- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

فبراير . 12, 2025 19:58 Back To List

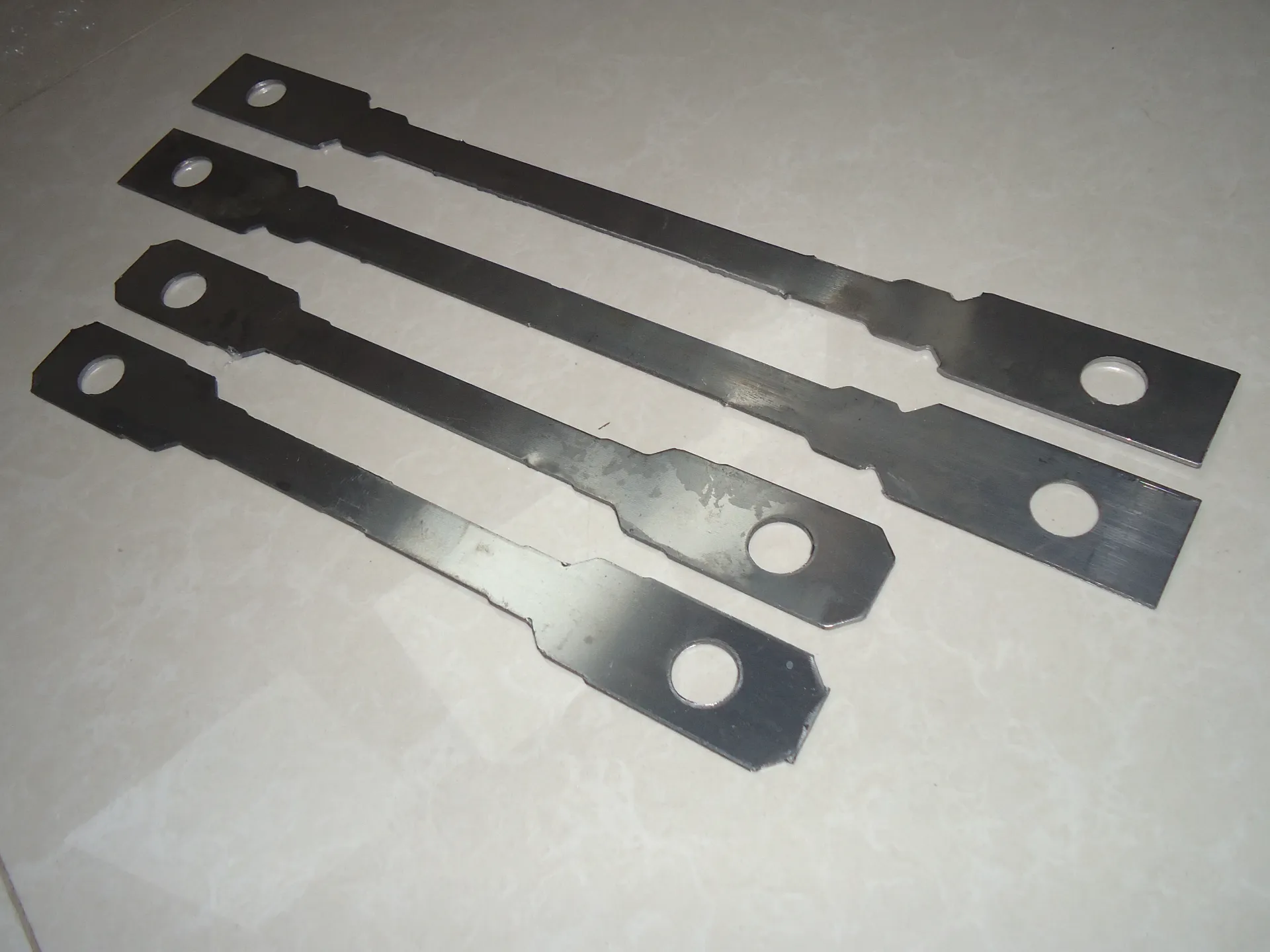

formwork snap ties

Navigating the world of formwork snap ties requires a nuanced understanding of both the technical characteristics and practical applications of these essential construction elements. As a critical component in concrete forming, snap ties are designed to hold formwork in place during the concrete pouring and curing process, ensuring structural stability and precision. With an increasing demand for cost-effective yet efficient building methods, the choice of formwork snap ties can significantly influence both the timeline and the budget of construction projects.

Additionally, expertise in the use of formwork snap ties extends to understanding their installation and removal procedures. Proper spacing and placement within the formwork setup are crucial, as well as awareness of the specific loads they are expected to withstand. Expertise in this area can significantly mitigate risks associated with premature tie failure, which can lead to costly repairs or structural compromise. Employing a skilled workforce familiar with the intricacies of snap tie application can further enhance both safety and efficiency on-site. In terms of authoritativeness and trustworthiness, it's clear that relying on established brands recognized for their engineering excellence can make a significant difference. These brands often provide comprehensive support, including detailed installation guides and tailored solutions for specific construction challenges. This support is not limited to literature but may include technical assistance and training sessions, ensuring that construction teams are well-equipped to implement these tools effectively. Ultimately, integrating formwork snap ties into construction strategies requires a balance of knowledge, quality materials, and practical application skills. By prioritizing these aspects, construction managers can achieve optimized outcomes, ensuring structures are not only built to code but also stand as testaments to modern engineering prowess. As construction methods continue to advance, the role of reliable formwork snap ties remains foundational to the building process, underscoring their importance in shaping the future of infrastructure development.

Additionally, expertise in the use of formwork snap ties extends to understanding their installation and removal procedures. Proper spacing and placement within the formwork setup are crucial, as well as awareness of the specific loads they are expected to withstand. Expertise in this area can significantly mitigate risks associated with premature tie failure, which can lead to costly repairs or structural compromise. Employing a skilled workforce familiar with the intricacies of snap tie application can further enhance both safety and efficiency on-site. In terms of authoritativeness and trustworthiness, it's clear that relying on established brands recognized for their engineering excellence can make a significant difference. These brands often provide comprehensive support, including detailed installation guides and tailored solutions for specific construction challenges. This support is not limited to literature but may include technical assistance and training sessions, ensuring that construction teams are well-equipped to implement these tools effectively. Ultimately, integrating formwork snap ties into construction strategies requires a balance of knowledge, quality materials, and practical application skills. By prioritizing these aspects, construction managers can achieve optimized outcomes, ensuring structures are not only built to code but also stand as testaments to modern engineering prowess. As construction methods continue to advance, the role of reliable formwork snap ties remains foundational to the building process, underscoring their importance in shaping the future of infrastructure development.

Prev:

Next:

Latest News

-

Durable Concrete Form Ties Enhanced with AI | Buy OnlineNewsJul.31,2025

-

High-Quality Roofing Materials for Durable Building SolutionsNewsJul.30,2025

-

High-Quality Scaffolding Pins for Sale – Durable & Secure Scaffold Toggle PinsNewsJul.30,2025

-

High-Quality Scaffold Coupling Pins for Secure ConnectionsNewsJul.29,2025

-

High-Quality Formwork Clamp for Concrete Construction, Durable & Easy to UseNewsJul.29,2025

-

High-Quality Prop Nut for Boats – Durable Propeller Nut with HandleNewsJul.29,2025

Products categories