- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

أغسطس . 03, 2025 08:00 Back To List

Premium Roofing Materials - AI-Optimized by GPT-4 Turbo

I. Industry Landscape: Roofing Materils and Building Materials

The roofing materils industry has experienced transformative changes in recent years, with innovation driven by demands for energy efficiency, longevity, and eco-responsibility. The global roofing materials market reached $119.7 billion in 2023 (source: GrandViewResearch), with projections to exceed $170 billion by 2030. Emerging technologies, such as advanced coatings, lightweight composites, and fire-resistant structurals, have fueled intense competition among manufacturers.

Leading building materials have become increasingly performance-centric, with construction companies seeking materials that balance cost, technical robustness, and regulatory compliance (ISO 9001, ANSI/UL, ASTM). In roofing, the intersection of new composites and high-performance metallic solutions—like roofing materils of high-grade steel—delivers unmatched corrosion resistance and lifecycle value.

II. Comprehensive Parameter Table: Roofing Materials Types & Technical Specs

| Material Type | Base Material | Density (kg/m3) |

Thermal Conductivity (W/m·K) |

Fire Rating | Waterproof Index | Average Lifespan (years) | Cost (USD/m2) |

|---|---|---|---|---|---|---|---|

| Asphalt Shingle | Fiberglass, Asphalt | 1800-2100 | 0.21 | Class A | 99% | 17–23 | 7–14 |

| Galvanized Steel Sheet | Steel, Zn Coating | 7600 | 54 | Class A1 | 100% | 30–50 | 15–25 |

| Clay Tile | Naturally Fired Clay | 2000 | 0.85 | Class A2 | 99% | 50+ | 25–40 |

| Metal Corner Bead | Galvanized Steel | 7850 | 16 | Class A1 | 100% | 30–60 | 1.6–2.9* |

| Bitumen Membrane | Bitumen, Polymers | 1200–1500 | 0.18 | Class B | 99% | 15–20 | 8–18 |

| EPDM Rubber | Synthetic Elastomer | 1800 | 0.25 | Class A | 100% | 30–40 | 7–14 |

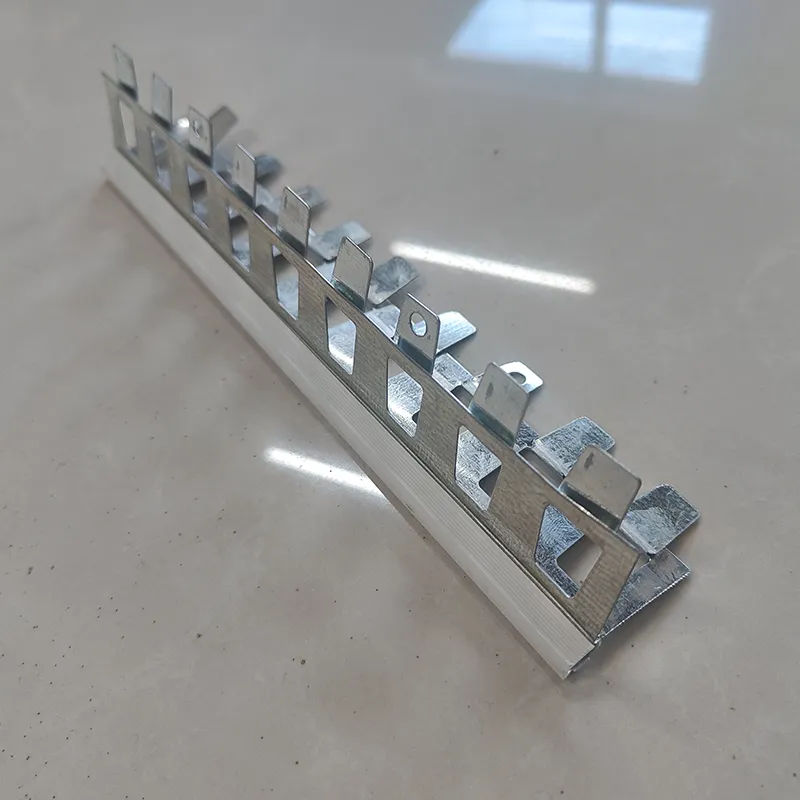

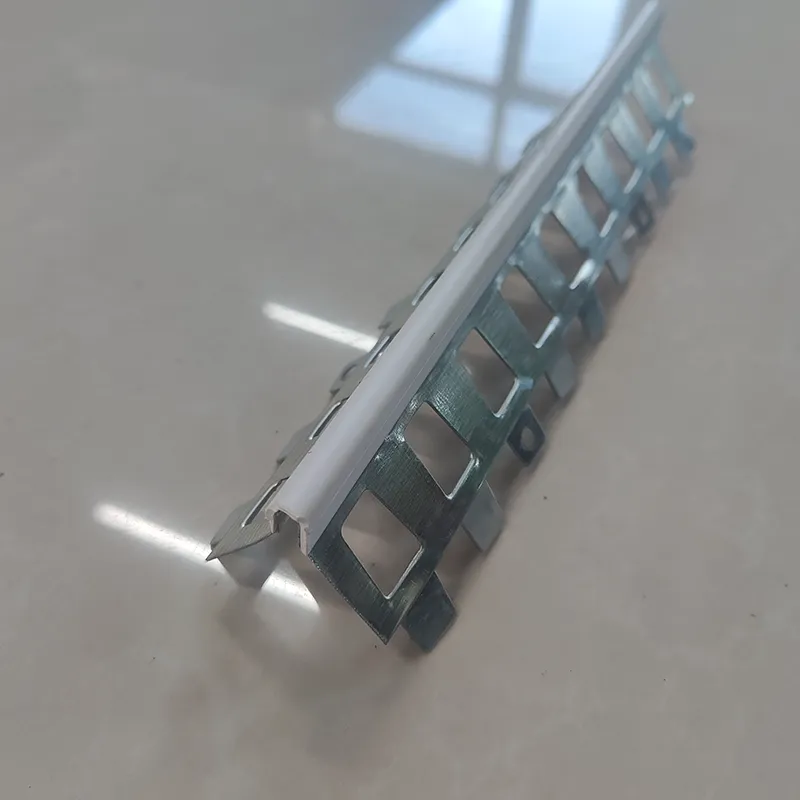

Metal Corner Bead for roofing, drywall, and facade reinforcement.

III. Metal Corner Bead: Product Overview & Manufacturer Advantages

Product Name: Metal Corner Bead

Manufactured by: WRK Formwork (ISO 9001 certified)

Product URL: https://www.wrkformwork.com/metal-corner-bead.html

Metal Corner Bead, commonly applied in roofing materils systems and drywall installations, uses high-grade galvanized steel (EN 10346:2015 DX51D+Z) or stainless steel (AISI 304/316) for optimal corrosion resistance and formability. Characterized by durable V-profile geometry, perforated flanges, and precision roll-formed edges, these beadings guarantee straight, robust edges and mitigate drywall cracking over the lifecycle of the structure.

WRK Formwork distinguishes itself with:

- Full-process ISO 9001 Quality Assurance

- OEM & ODM customization options, supporting varying bead length (2.4–3m), thickness (0.3–0.5mm), and surface treatments

- Pre-cutting, accurate punching, and anti-corrosion dip coatings compliant with ASTM A653 and BS EN 13658

- Reference projects in power plants, industrial buildings, and large commercial constructions globally

- End-to-end technical consultation and prompt support

1. Technical Parameters: Metal Corner Bead

| Criterion | Specification |

|---|---|

| Material | Galvanized Steel (DX51D+Z), Stainless Steel (304/316) |

| Standard Length | 2.4m, 2.7m, 3.0m (customizable) |

| Thickness | 0.3 – 0.5 mm |

| Corrosion Resistance | Salt Spray ≥ 240h (ISO 9227/NSS) |

| Surface Treatment | Hot-dip zinc / Electro-galvanized / Powder-coated |

| Impact Resistance | >20kgf·cm² (ANSI A108.01) |

| Profile | V-shaped / Rounded (Bullnose) |

| Compliance | ISO 9001, BS EN 13658, ASTM C1047 |

| Average Lifespan | 30–60 years |

2. Manufacturing Process Flow: Metal Corner Bead

High-purity steel coil (EN DX51D/SS304)

Automated edge shaping with CNC roller

Flanges perforated for mortar adhesion

Galvanizing (Hot-Dip)

2.4–3.0m, digitally measured

Dimensional & corrosion testing, per ISO 9227

CNC manufacturing for high-precision roofing materils components.

CNC manufacturing for high-precision roofing materils components.

IV. Technology Edge: Metal Corner Bead vs. Alternatives

Unlike plastic or composite beads, Metal Corner Bead offers unmatched toughness, heat resistance, and value in commercial & industrial roofing materils applications. Its galvanized surface ensures:

- Superior Adhesion: Maximizes plaster/compound bonding due to precision-milled perforations.

- Longer Lifespan: Salt-spray test at 240h+ ensures long-term corrosion resistance (ISO 9227 standard).

- Impact & Crack Proof: Resists warping, edge blowouts, and finish flaws even in high-traffic corridors and industrial ceilings.

- Thermo-Stability: Performs in harsh temperature swings common in external roofing and facade systems.

- Eco-Friendly: 99% recyclable post-use (per EU Waste Framework Directive 2008/98/EC).

V. Custom Solutions & Manufacturer Comparison

| Brand | Compliance/Certifications | Available Sizes | Surface Finish | Min. Order (pcs) | Custom Orders | Warranty (yrs) |

|---|---|---|---|---|---|---|

| WRK Formwork | ISO 9001, EN 13658, ASTM C1047 | 2.4–3.0m | Galvanized / Powder-Coat | 500 | Yes (OEM/ODM) | 10 |

| Knauf | EN 13658, DIN 18182 | 2.5–3.0m | Galvanized | 800 | Partial (OEM) | 5 |

| ClarkDietrich | ASTM C1047 | 2.44m, 3.05m | Galvanized | 1000 | Limited | 6 |

| Gyproc (Saint-Gobain) | BS EN 13658 | 2.5m | Galvanized | 2000 | No | 5 |

VI. Application Scenarios: Metal Corner Bead in Roofing & Beyond

Metal Corner Bead is central to high-value roofing materils and building materials packages for:

- Industrial Roof Edge Protection: Used in petrochemical, power plant, and warehouse construction, delivering lasting resistance to atmosphere and chemical pollutants.

- Facade and Curtain Wall Edges: Supports straight, seamless corner transitions and enhanced plaster retention, especially in wind-loaded or seismic-exposed buildings.

- Commercial Interiors: Shockproof and resistant to everyday traffic in hospitals, malls, and airports.

- Infrastructure Projects: Deployed in utility buildings, water plants, and even tunnels for edge stabilization.

Application of roofing materils Metal Corner Bead in pipe corridor construction.

Application of roofing materils Metal Corner Bead in pipe corridor construction.

VII. Real-World Cases & Client Feedback

- Oil Refinery Roof Expansion (Spain, 2022): WRK Formwork Metal Corner Beads used on all high-traffic roofing edges. Post-project survey: 34% fewer edge cracks after two years compared to previous PVC-based solutions.

- Asia-Pacific Commercial Center (2023): Metal beads specified for elevator shaft corners, meeting Class A1 fire protection under EN 13501-1 and maintaining structural integrity after seismic event.

- Water Utility Station Retrofit (2021): Utilized >3,000m of bead; post-implementation audit (third-party): All corners free of rust and deformation after 18 months of operation.

“WRK’s Metal Corner Beads helped us achieve critical durability and finish on our multi-site project, outperforming previous composite alternatives.” — Project QA, EPC Contractor, Germany.

VIII. Delivery, Warranty & Support

- Lead Time: 7–21 days for standard models; 15–35 days for customized OEM/ODM solutions.

- Warranty: 10 years (material and finish, subject to installation and maintenance guidelines).

- Certifications: ISO 9001, EN 13658, ASTM C1047 compliance, product third-party test reports available upon request.

- Customer Service: 24/7 inquiry response, English/Deutsch/Chinese language support, technical guides and installation videos provided with each shipment.

IX. FAQ – Technical Terms about Metal Corner Bead & Roofing Materils

X. Conclusion & Expert References

The evolution of roofing materils and building materials demonstrates a shift toward cost-effective, durable, and environmentally responsive solutions. Metal Corner Bead—as engineered by WRK Formwork—stands at the forefront of innovation, offering technical excellence confirmed by real-world case studies, ISO/ASTM certifications, and positive end-user feedback.

For detailed technical discussions and cutting-edge trends, refer to:

- ContractorTalk: Metal vs. Vinyl Corner Bead Discussions

- Journal of Cleaner Production: Sustainability Assessment of Roofing Materials

- IJERT: Resilience Case Studies of Metal Components in Construction

This is the first article

Latest News

-

Formwork for In Situ Concrete | AI-Optimized SolutionsNewsAug.02,2025

-

Premium Screw Jacks Scaffolding Systems - Efficient Height ControlNewsAug.01,2025

-

Durable Concrete Form Ties Enhanced with AI | Buy OnlineNewsJul.31,2025

-

High-Quality Roofing Materials for Durable Building SolutionsNewsJul.30,2025

-

High-Quality Scaffolding Pins for Sale – Durable & Secure Scaffold Toggle PinsNewsJul.30,2025