- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

лют . 14, 2025 04:58 Back To List

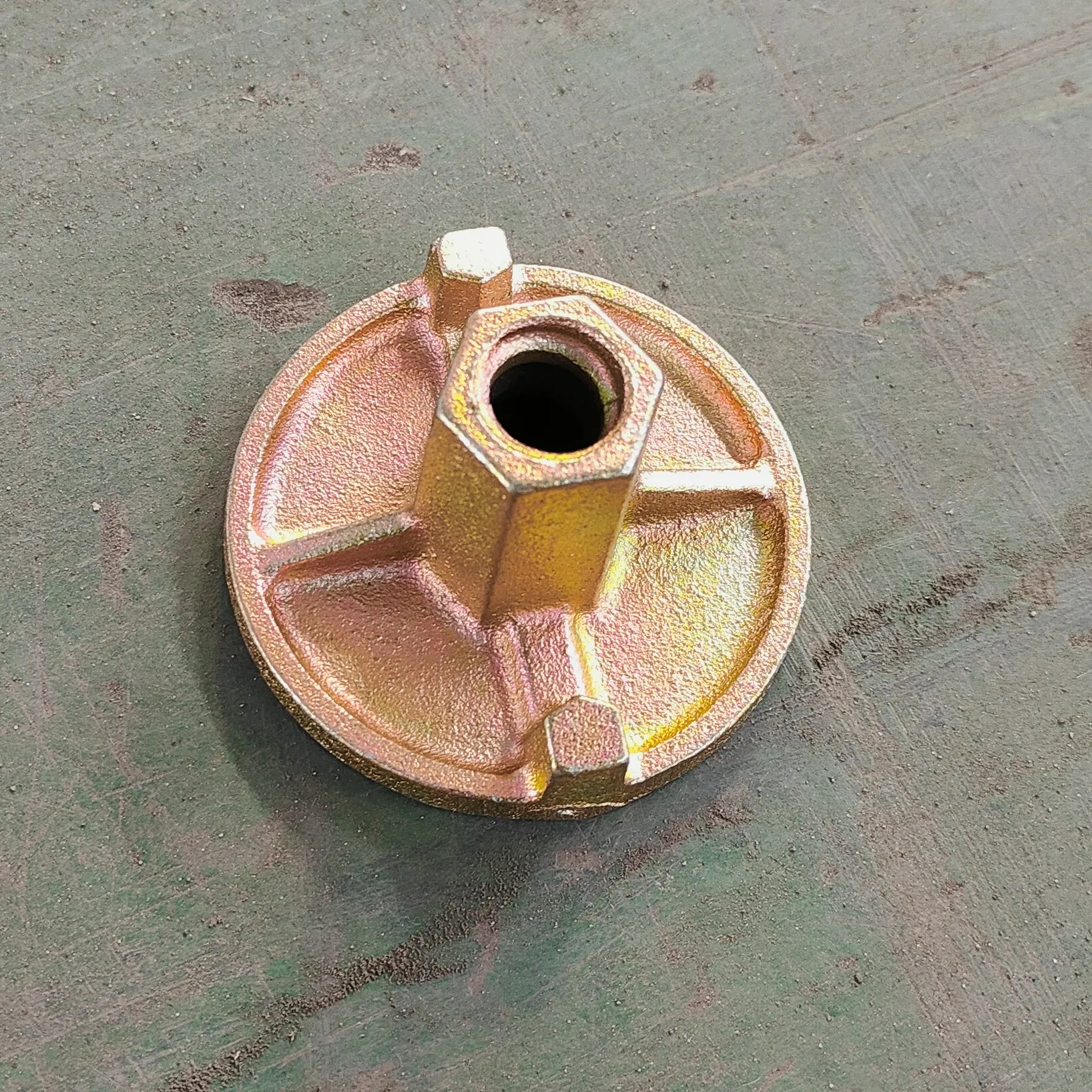

clamp for shuttering

Clamps for shuttering play a pivotal role in the construction industry, serving as essential components in concrete formwork systems. These robust devices ensure the stability and alignment of shuttering panels during the pouring and curing of concrete, ultimately impacting the quality and precision of the final structure. With the evolving demands of modern construction projects, understanding the features, applications, and benefits of these clamps can significantly enhance project outcomes.

In terms of trustworthiness, industry standards and certifications play a crucial role. Renowned clamp manufacturers adhere to rigorous quality assessments and comply with international standards. This not only assures the performance of each clamp but also builds trust among construction firms, project managers, and clients. Clamps that meet ISO certifications or other industry-specific approvals guarantee reliability and long-term performance, factors that are critical in maintaining structural integrity. It is also essential to consider the clamp’s resistance to repetitive use. In large construction projects, formwork is often reused, and clamps must withstand repeated application without degradation in performance. The longevity of a clamp for shuttering directly impacts cost-effectiveness and sustainability, reducing the need for frequent replacements and contributing to more environmentally friendly construction practices. Educational and professional resources often highlight case studies where the right choice and application of clamps have led to significant advancements in construction efficiency and safety. By investing in high-quality clamps and employing them with precision and care, construction professionals not only streamline their processes but also ensure the enduring success of their projects. In conclusion, clamps for shuttering stand as foundational tools that affect the overarching quality of construction projects. Their selection, application, and maintenance require a blend of experience, expertise, authoritative knowledge, and a strong foundation of trust in their quality. As technology and materials evolve, so too will the innovation in clamp design, ultimately leading to more efficient, safe, and sustainable construction practices worldwide.

In terms of trustworthiness, industry standards and certifications play a crucial role. Renowned clamp manufacturers adhere to rigorous quality assessments and comply with international standards. This not only assures the performance of each clamp but also builds trust among construction firms, project managers, and clients. Clamps that meet ISO certifications or other industry-specific approvals guarantee reliability and long-term performance, factors that are critical in maintaining structural integrity. It is also essential to consider the clamp’s resistance to repetitive use. In large construction projects, formwork is often reused, and clamps must withstand repeated application without degradation in performance. The longevity of a clamp for shuttering directly impacts cost-effectiveness and sustainability, reducing the need for frequent replacements and contributing to more environmentally friendly construction practices. Educational and professional resources often highlight case studies where the right choice and application of clamps have led to significant advancements in construction efficiency and safety. By investing in high-quality clamps and employing them with precision and care, construction professionals not only streamline their processes but also ensure the enduring success of their projects. In conclusion, clamps for shuttering stand as foundational tools that affect the overarching quality of construction projects. Their selection, application, and maintenance require a blend of experience, expertise, authoritative knowledge, and a strong foundation of trust in their quality. As technology and materials evolve, so too will the innovation in clamp design, ultimately leading to more efficient, safe, and sustainable construction practices worldwide.

Prev:

Next:

Latest News

-

Premium Screw Jacks Scaffolding Systems - Efficient Height ControlNewsAug.01,2025

-

Durable Concrete Form Ties Enhanced with AI | Buy OnlineNewsJul.31,2025

-

High-Quality Roofing Materials for Durable Building SolutionsNewsJul.30,2025

-

High-Quality Scaffolding Pins for Sale – Durable & Secure Scaffold Toggle PinsNewsJul.30,2025

-

High-Quality Scaffold Coupling Pins for Secure ConnectionsNewsJul.29,2025

-

High-Quality Formwork Clamp for Concrete Construction, Durable & Easy to UseNewsJul.29,2025

Products categories