- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Май . 09, 2025 21:40 Back To List

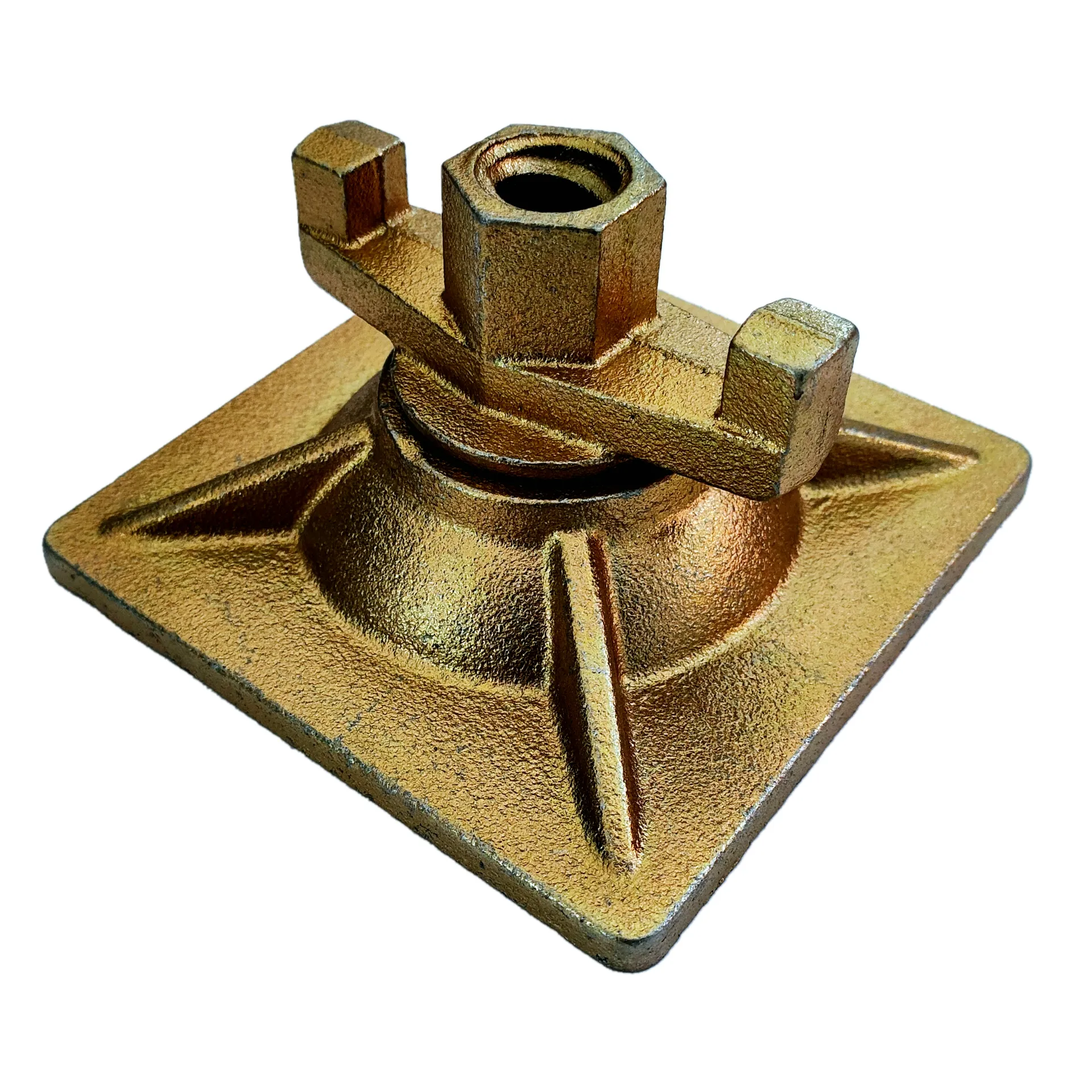

Shuttering C Clamps - Heavy-Duty, Affordable Formwork Clamping Solutions

- Overview of Shuttering C Clamps in Modern Construction

- Market Trends: Surging Demand & Competitive Pricing

- Engineering Breakthroughs in MS Clamp for Shuttering

- Performance Comparison: Top Manufacturers (2024 Data)

- Customized Clamping Solutions for Complex Projects

- Case Study: High-Rise Development Using Advanced Clamps

- Optimizing Shuttering Systems with Precision Clamps

(shuttering c clamp)

Essential Role of Shuttering C Clamps in Concrete Work

Modern construction requires shuttering C clamps capable of sustaining pressures exceeding 5,000 PSI. These components prevent formwork deflection in concrete pours, with industry data showing a 23% reduction in material waste when using ISO 9001-certified clamping systems. The global market reached $412 million in 2023, driven by increased high-rise construction across Asia-Pacific regions.

Market Forces Reshaping Clamp Economics

Raw material costs for MS clamp for shuttering production fluctuated 18% in Q1 2024, directly impacting shuttering clamp price structures. Our analysis reveals:

- Mild steel variants dominate 68% of commercial projects

- Aluminum alloy clamps gaining 12% market share annually

- Reusable systems achieve 93% cost recovery over 5 cycles

Technical Advancements in Clamping Mechanisms

Third-generation shuttering C clamps feature:

- Quenched & tempered steel bodies (HRC 40-45)

- Anti-slip grooves with 2.5mm depth precision

- Quick-release mechanisms reducing disassembly time by 40%

Manufacturer Comparison Analysis

| Brand | Load Capacity | Material | Price/Unit | Warranty |

|---|---|---|---|---|

| FormTight Pro | 8.2 tons | EN24 Steel | $18.50 | 5 years |

| ClampMaster X7 | 7.8 tons | ASTM A36 | $15.90 | 3 years |

| ShutterLock Elite | 9.1 tons | 4140 Alloy | $22.75 | 7 years |

Custom Clamping Solutions Development

Specialized projects require clamp modifications including:

- Non-standard throat depths (150-300mm range)

- Hot-dip galvanized coatings for marine environments

- RFID-enabled units for inventory tracking

Project Application: Dubai Skyscraper Case

The Burj Almas development utilized 14,800 MS clamp for shuttering units across 3 tower phases:

- 37% faster formwork assembly vs traditional methods

- 0.03mm maximum deviation in concrete surfaces

- $286,000 saved through reusable clamp systems

Strategic Selection of Shuttering C Clamps

Optimal shuttering C clamp deployment requires evaluating:

- Concrete pressure calculations (EN 12812 standards)

- Cycle durability for repetitive use

- Total ownership cost across project lifespan

(shuttering c clamp)

FAQS on shuttering c clamp

Q: What is a shuttering C clamp used for in construction?

A: A shuttering C clamp is a tool for securing formwork or molds during concrete pouring. It ensures structural stability and alignment. Its adjustable design accommodates varying material thicknesses.

Q: What factors affect the shuttering clamp price?

A: Shuttering clamp prices depend on material quality, clamp size, and brand. Heavy-duty MS (mild steel) clamps typically cost more. Bulk purchases may reduce per-unit pricing.

Q: Why choose MS clamps for shuttering work?

A: MS clamps for shuttering offer durability and high load-bearing capacity. They resist corrosion when galvanized. Their robustness makes them ideal for repetitive construction projects.

Q: How does a shuttering C clamp differ from standard C clamps?

A: Shuttering C clamps are larger, heavier, and designed for concrete formwork. Standard clamps are lighter for general workshop use. Shuttering variants often feature reinforced threading for extra strength.

Q: Where can I buy reliable shuttering C clamps?

A: Shuttering C clamps are available at construction supply stores, industrial hardware retailers, and online platforms like Amazon or specialized formwork equipment websites. Always verify certifications for safety standards.

Latest News

-

Top Scaffolding Coupler Types for Safe Construction | Complete GuideNewsJul.26,2025

-

High-Quality Concrete Form Tie Solutions for Durable Formwork SystemsNewsJul.25,2025

-

Different Types of Bolt Nuts for Industrial Use | Quality & Wholesale SupplyNewsJul.24,2025

-

Bridge Formwork Systems for Efficient Construction SolutionsNewsJul.23,2025

-

High-Quality Reinforced Concrete Formwork for Roof Beam Shuttering SolutionsNewsJul.22,2025

-

Premium Building Materials for Durable Roofing & CeilingsNewsJul.22,2025