- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 17, 2025 15:47 Back To List

types of couplers in scaffolding

Scaffolding is a critical component in construction, ensuring worker safety and facilitating structures that reach otherwise inaccessible areas. Central to the effective use of scaffolding are couplers, the connectors that hold the scaffolding components together. With vital importance, understanding the various types of scaffolding couplers not only enhances construction safety but also optimizes performance. Below, we delve into different types of couplers, sharing insights from seasoned professionals, which provide an authoritative perspective on how each type functions and its best use scenarios.

Board Retaining Couplers Used to secure scaffold boards in place, these couplers prevent dislodging, ensuring a stable platform for workers. Tradespeople skilled in scaffolding stress the necessity of board retaining couplers on active sites, where worker movement can unsettle boards. Reliability comes from their precise grip, and their effectiveness depends on the continuous maintenance of tension and condition checks. Gravlock Couplers Specifically engineered for connecting steel beams, gravlock couplers offer a unique solution in scaffolding for industrial environments. Renowned for their heavy-duty applications, experts advocate for their use in high-load scenarios due to their dependable clamping power. The authority of gravlock couplers comes from their robust fabrication, typically from high-tensile materials, which provides peace of mind in terms of safety. Pressed Steel and Drop Forged Couplers These two types focus on manufacturing techniques affecting the strength and cost balance. Pressed steel couplers are valued for their affordability and lightweight nature, ideal for budget-conscious projects without compromising safety. Conversely, drop forged couplers, praised for their unmatched durability, are recommended by leading construction engineers for high-stress environments where reliability cannot be compromised. Wire Rope Couplers In specialized scaffolding applications such as suspended scaffolds, wire rope couplers offer additional security by enabling harnessing systems to integrate with the scaffold structure. Their importance is underscored by safety experts, who highlight their role in preventing falls. Trustworthiness is ensured through regular inspection and testing protocols, a non-negotiable practice advised by industry watchdogs. Understanding the various types of couplers used in scaffolding is not just about knowing their functions but also respecting the standards that guarantee safety and effectiveness. Through expertise and a nuanced appreciation of their roles, construction professionals can maximize both the safety and efficiency of their scaffolding systems. By remaining guided by authoritative insights and empirical evidence, you ensure that each piece is utilized to its fullest potential, establishing a safe, reliable work environment.

Board Retaining Couplers Used to secure scaffold boards in place, these couplers prevent dislodging, ensuring a stable platform for workers. Tradespeople skilled in scaffolding stress the necessity of board retaining couplers on active sites, where worker movement can unsettle boards. Reliability comes from their precise grip, and their effectiveness depends on the continuous maintenance of tension and condition checks. Gravlock Couplers Specifically engineered for connecting steel beams, gravlock couplers offer a unique solution in scaffolding for industrial environments. Renowned for their heavy-duty applications, experts advocate for their use in high-load scenarios due to their dependable clamping power. The authority of gravlock couplers comes from their robust fabrication, typically from high-tensile materials, which provides peace of mind in terms of safety. Pressed Steel and Drop Forged Couplers These two types focus on manufacturing techniques affecting the strength and cost balance. Pressed steel couplers are valued for their affordability and lightweight nature, ideal for budget-conscious projects without compromising safety. Conversely, drop forged couplers, praised for their unmatched durability, are recommended by leading construction engineers for high-stress environments where reliability cannot be compromised. Wire Rope Couplers In specialized scaffolding applications such as suspended scaffolds, wire rope couplers offer additional security by enabling harnessing systems to integrate with the scaffold structure. Their importance is underscored by safety experts, who highlight their role in preventing falls. Trustworthiness is ensured through regular inspection and testing protocols, a non-negotiable practice advised by industry watchdogs. Understanding the various types of couplers used in scaffolding is not just about knowing their functions but also respecting the standards that guarantee safety and effectiveness. Through expertise and a nuanced appreciation of their roles, construction professionals can maximize both the safety and efficiency of their scaffolding systems. By remaining guided by authoritative insights and empirical evidence, you ensure that each piece is utilized to its fullest potential, establishing a safe, reliable work environment.

Next:

Latest News

-

Premium Roofing Materials - AI-Optimized by GPT-4 TurboNewsAug.03,2025

-

Formwork for In Situ Concrete | AI-Optimized SolutionsNewsAug.02,2025

-

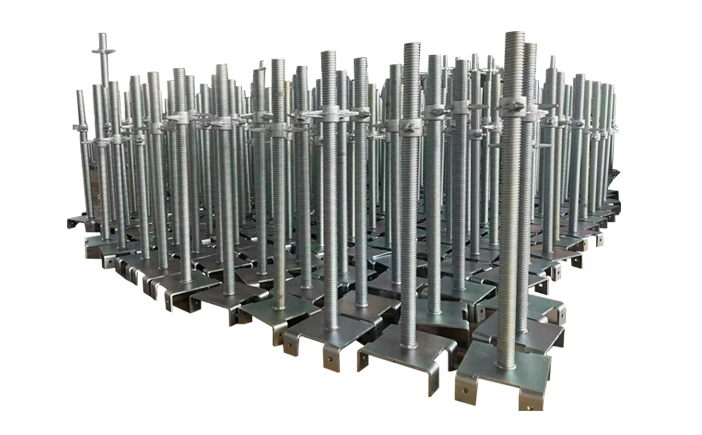

Premium Screw Jacks Scaffolding Systems - Efficient Height ControlNewsAug.01,2025

-

Durable Concrete Form Ties Enhanced with AI | Buy OnlineNewsJul.31,2025

-

High-Quality Roofing Materials for Durable Building SolutionsNewsJul.30,2025

-

High-Quality Scaffolding Pins for Sale – Durable & Secure Scaffold Toggle PinsNewsJul.30,2025

Products categories