- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

फरवरी . 13, 2025 09:22 Back To List

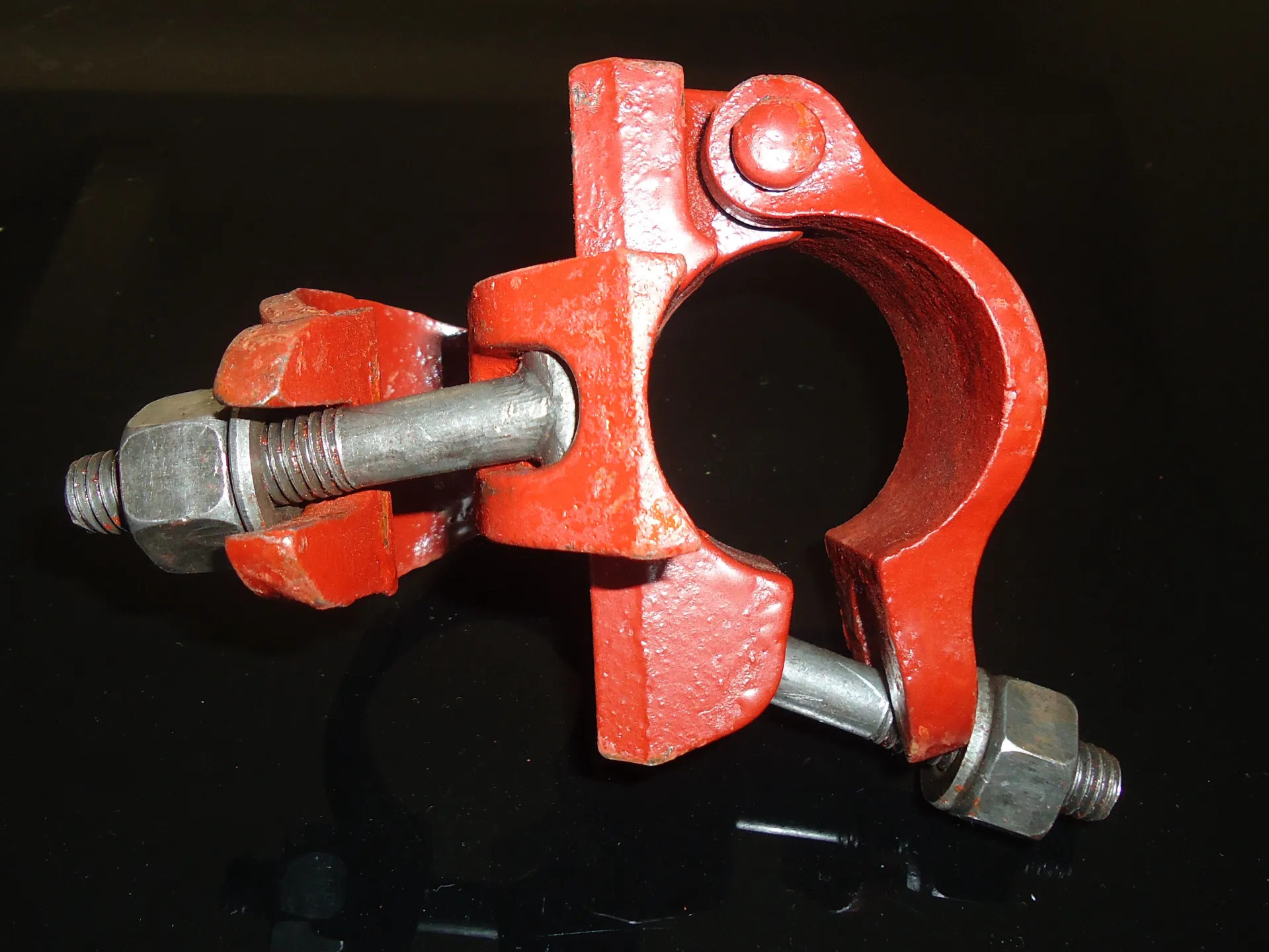

tie rod and wing nut

The integration of a tie rod and wing nut system in various applications highlights the importance of reliable fastening solutions across industries. From industrial machinery to home improvement projects, these small yet crucial components play a significant role in ensuring stability and safety.

An authority in fastening solutions emphasizes the certification and testing of tie rods and wing nuts to meet standards such as ASME or ISO. These certifications ensure that components are capable of withstanding specified loads and environmental conditions. Adherence to these standards instills confidence in the products’ reliability and safety, which is critical as these components often serve as safeguards against structural failures. The trustworthiness of a tie rod and wing nut system also relies on precise manufacturing tolerances. High-quality machining ensures perfect fitments that eliminate any unwanted play in the connections, which could otherwise lead to compromises under stress. Quality control processes are vital in ensuring that every component meets stringent specifications, providing users with peace of mind. Real-world experience demonstrates the efficacy of tie rods and wing nuts across diverse applications. In bridge construction, for instance, tie rods are used in suspending large decks, where they endure tremendous tension. The use of wing nuts allows engineers to make field adjustments with ease, ensuring that even under load, the structure's alignment and integrity remain intact. Similarly, in the agricultural sector, these components are deployed in machinery that requires quick reconfigurations, again highlighting their versatility and reliability. Consumer reviews and long-term usage data provide additional insights into the practical benefits of these components. Feedback often points to the ease of use and the longevity of corrosion-resistant options, which maintain performance even after prolonged exposure to outdoor conditions. Such testimonials are invaluable for identifying the reliability of specific brands and models in real-world scenarios. In conclusion, the tie rod and wing nut represent a fundamental solution in the toolkit of structural engineering and machinery assembly. Their combined use underscores a balance of strength, flexibility, and ease of use that caters to the demanding requirements of modern applications. For industries prioritizing safety, efficiency, and adaptability, this system stands out as a trusted choice, bolstered by expert design, rigorous testing, and real-world validation. Investing in quality tie rods and wing nuts is a decision that supports long-term resilience and performance across various sectors.

An authority in fastening solutions emphasizes the certification and testing of tie rods and wing nuts to meet standards such as ASME or ISO. These certifications ensure that components are capable of withstanding specified loads and environmental conditions. Adherence to these standards instills confidence in the products’ reliability and safety, which is critical as these components often serve as safeguards against structural failures. The trustworthiness of a tie rod and wing nut system also relies on precise manufacturing tolerances. High-quality machining ensures perfect fitments that eliminate any unwanted play in the connections, which could otherwise lead to compromises under stress. Quality control processes are vital in ensuring that every component meets stringent specifications, providing users with peace of mind. Real-world experience demonstrates the efficacy of tie rods and wing nuts across diverse applications. In bridge construction, for instance, tie rods are used in suspending large decks, where they endure tremendous tension. The use of wing nuts allows engineers to make field adjustments with ease, ensuring that even under load, the structure's alignment and integrity remain intact. Similarly, in the agricultural sector, these components are deployed in machinery that requires quick reconfigurations, again highlighting their versatility and reliability. Consumer reviews and long-term usage data provide additional insights into the practical benefits of these components. Feedback often points to the ease of use and the longevity of corrosion-resistant options, which maintain performance even after prolonged exposure to outdoor conditions. Such testimonials are invaluable for identifying the reliability of specific brands and models in real-world scenarios. In conclusion, the tie rod and wing nut represent a fundamental solution in the toolkit of structural engineering and machinery assembly. Their combined use underscores a balance of strength, flexibility, and ease of use that caters to the demanding requirements of modern applications. For industries prioritizing safety, efficiency, and adaptability, this system stands out as a trusted choice, bolstered by expert design, rigorous testing, and real-world validation. Investing in quality tie rods and wing nuts is a decision that supports long-term resilience and performance across various sectors.

Prev:

Next:

Latest News

-

High-Quality Roofing Materials for Durable Building SolutionsNewsJul.30,2025

-

High-Quality Scaffolding Pins for Sale – Durable & Secure Scaffold Toggle PinsNewsJul.30,2025

-

High-Quality Scaffold Coupling Pins for Secure ConnectionsNewsJul.29,2025

-

High-Quality Formwork Clamp for Concrete Construction, Durable & Easy to UseNewsJul.29,2025

-

High-Quality Prop Nut for Boats – Durable Propeller Nut with HandleNewsJul.29,2025

-

High-Quality Scaffolding Joint Pin for Secure ConnectionsNewsJul.28,2025

Products categories