- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

lip . 12, 2025 15:53 Natrag na popis

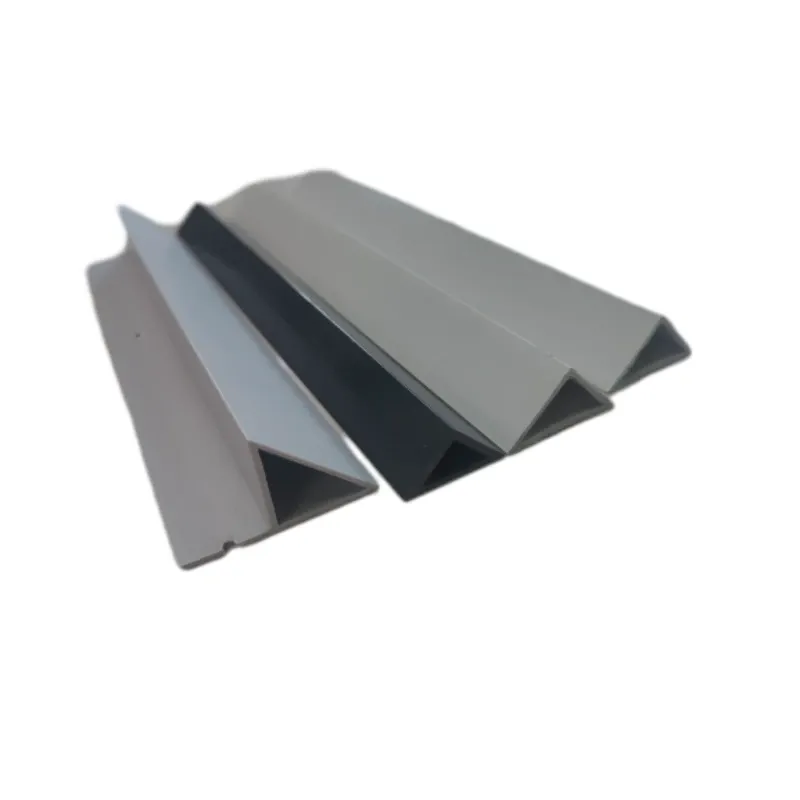

Innovations in PVC Profile Technology

The construction industry continues to evolve, driven by advancements in materials like PVC profile products. From ekstruzija prozorskog profila systems to specialized pvc clear rubber profile seals, these components are revolutionizing how buildings achieve durability, energy efficiency, and aesthetic appeal. PVC door profile designs, in particular, have become indispensable for modern architecture. This article explores the transformative role of PVC profile technologies, their manufacturing processes, and their applications in contemporary construction.

Understanding PVC Profile Manufacturing

PVC profile manufacturing involves extruding polyvinyl chloride (PVC) into precise shapes tailored for specific applications. The process begins with raw PVC resin blended with stabilizers, lubricants, and pigments. This mixture is heated and forced through a die in a technique called ekstruzija prozorskog profila, which shapes the material into frames for windows, doors, and other structural elements. The versatility of PVC allows for customization, enabling manufacturers to produce everything from rigid pvc door profile frames to flexible pvc clear rubber profile gaskets.

The durability of PVC profile products stems from their resistance to moisture, corrosion, and UV radiation. These properties make them ideal for both indoor and outdoor use, ensuring longevity even in harsh climates.

Energy Efficiency Through Window Profile Extrusion

One of the standout applications of PVC profile technology is in ekstruzija prozorskog profila. Modern windows demand energy-efficient solutions, and PVC’s insulating properties make it a preferred material. Multi-chamber designs created via ekstruzija prozorskog profila reduce heat transfer, lowering energy consumption for heating and cooling.

Additionally, pvc clear rubber profile seals are often integrated into window systems to enhance airtightness. These transparent seals prevent drafts and water infiltration while maintaining visibility, ensuring that functionality does not compromise aesthetics.

Versatility of PVC Clear Rubber Profile in Design

The pvc clear rubber profile exemplifies innovation in flexible PVC applications. Unlike traditional opaque rubber, this transparent variant is used for sealing edges in glass partitions, shower enclosures, and furniture. Its clarity ensures discreet functionality, blending seamlessly with modern minimalist designs.

Moreover, pvc clear rubber profile materials are non-toxic and recyclable, aligning with sustainability goals. Their flexibility allows for easy installation, reducing labor costs and waste during construction.

Enhancing Security with PVC Door Profile Innovations

PVC door profile systems have redefined entryway security and insulation. These profiles are engineered to accommodate advanced locking mechanisms and reinforced cores, providing robust protection against forced entry. The hollow chambers within pvc door profile frames also allow for the integration of steel reinforcements, further enhancing strength.

Beyond security, PVC door profile designs prioritize thermal and acoustic insulation. By combining airtight pvc clear rubber profile seals with multi-layered frames, these doors significantly reduce noise pollution and energy loss.

PVC Profile FAQS

What makes PVC profile materials ideal for construction?

PVC profile products are lightweight, durable, and resistant to environmental factors like moisture and UV radiation. Their adaptability in manufacturing processes, such as ekstruzija prozorskog profila, allows for energy-efficient and cost-effective solutions.

How does window profile extrusion improve energy efficiency?

Ekstruzija prozorskih profila creates multi-chambered frames that trap air, reducing thermal transfer. Paired with pvc clear rubber profile seals, these windows prevent drafts, lowering heating and cooling costs.

Can pvc clear rubber profile be used outdoors?

Yes, pvc clear rubber profile materials are UV-stabilized, making them suitable for outdoor applications like patio doors and greenhouse seals. Their transparency and flexibility ensure long-lasting performance without visual intrusion.

Why choose PVC door profile systems over traditional materials?

PVC door profile frames offer superior insulation, security, and low maintenance. They resist warping, rotting, and corrosion, unlike wood or metal, ensuring longevity in diverse climates.

Are PVC profile products environmentally friendly?

Yes, many PVC profile products are recyclable. Innovations like pvc clear rubber profile and energy-efficient ekstruzija prozorskog profila systems align with green building standards by reducing waste and energy consumption.

A recurring theme across PVC profile applications is their alignment with sustainable construction practices. Many PVC profile products are recyclable, reducing waste in landfills. Innovations like energy-efficient ekstruzija prozorskog profila systems and eco-friendly pvc clear rubber profile materials further support green building certifications such as LEED. Additionally, the longevity of PVC profile components minimizes the need for frequent replacements, lowering the environmental impact over a building’s lifecycle.

As the construction industry shifts toward net-zero goals, PVC profile technologies are poised to play an even greater role. Ongoing research focuses on improving recyclability, reducing carbon footprints in manufacturing, and expanding the use of pvc clear rubber profile i pvc door profile systems in smart buildings.

The integration of PVC profile technologies—such as ekstruzija prozorskog profila, pvc clear rubber profile, i pvc door profile—has transformed modern construction. These materials offer unmatched durability, energy efficiency, and design flexibility, making them essential for sustainable and secure buildings. As the industry advances, PVC profile innovations will continue to play a pivotal role in shaping the future of architecture.

Najnovije vijesti

-

Tie Nut Applications In Concrete FormworkVijestiJul.23,2025

-

The Advantages of Using Stainless Steel Shuttering Tie RodsVijestiJul.23,2025

-

PVC Water Stopper Chemical Resistance PropertiesVijestiJul.23,2025

-

Prop Nuts: How to Identify Signs of Wear and TearVijestiJul.23,2025

-

Packaging Requirements for Adjustable Jack BasesVijestiJul.23,2025

-

Maintenance Tips for Scaffolding Props and Their SleevesVijestiJul.23,2025