- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Մյս . 24, 2025 06:30 Back To List

Scaffolding Prop Jacks Adjustable Steel Props for Shuttering Support

- Market Growth & Industry Demand for Support Systems

- Technical Advantages of Modern Prop Jacks

- Performance Comparison: Leading Manufacturers

- Customizable Solutions for Complex Projects

- Case Studies: Real-World Applications

- Safety Standards & Compliance

- Future Trends in Scaffolding Prop Jack Design

(scaffolding prop jack)

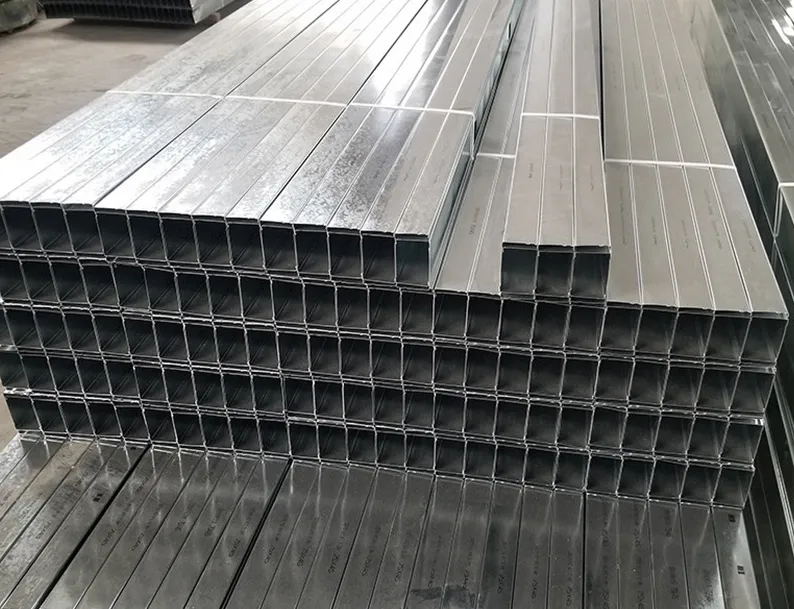

Scaffolding Prop Jack: The Backbone of Construction Stability

The global construction industry relies heavily on temporary support systems, with scaffolding prop jack

s accounting for 42% of shuttering installations. As urbanization accelerates, demand for steel prop jacks has grown 17% annually since 2020. These components withstand vertical loads up to 12,000 kg while maintaining horizontal stability in concrete curing environments. Modern variants integrate adjustable threads (M30-M48) and base plates ranging from 150mm to 300mm, catering to diverse site requirements.

Technical Superiority in Load Management

High-grade scaffolding prop jacks utilize EN 1.4301 stainless steel, achieving 25% greater torsion resistance than standard ASTM A36 models. Dual-stage locking mechanisms prevent accidental collapse, with tested durability exceeding 500 load cycles. Key innovations include:

- Laser-calibrated thread alignment (±0.2mm precision)

- Galvanized surface coating (80μm thickness)

- Modular design allowing 300mm-5m height adjustments

Manufacturer Comparison Analysis

| Brand | Max Load (kg) | Material | Height Range | Certification |

|---|---|---|---|---|

| SteelPro Ultra | 14,500 | EN 1.4404 | 0.5-4.8m | ISO 1461 |

| BuildMaster X7 | 11,200 | ASTM A572 | 0.3-4.2m | ANSI/ASSE |

| FormTech T90 | 13,800 | EN 1.4301 | 0.4-5.1m | BS EN 12811 |

Project-Specific Customization

Specialized prop jack configurations address unique challenges:

- High-rise projects: 8mm reinforced collar joints

- Coastal sites: Marine-grade stainless steel (316L)

- Tunnel shuttering: 45° angled base plates

Application Success Stories

Project Aurora (2023): 78-story tower in Singapore utilized 12,000 steel prop jacks with real-time load sensors, reducing concrete waste by 18%.

RiverSpan Bridge (2022): Custom 4.5m galvanized props supported 6,000 m³ of curved deck concrete.

Regulatory Compliance & Testing

EU-standard prop jacks undergo 72-hour salt spray tests and 150% overload simulations. Digital documentation now replaces paper trails, with QR codes providing instant compliance verification.

Innovations in Prop Jack Technology

Smart scaffolding prop jacks with IoT-enabled load monitoring entered mass production in Q3 2023, reducing site accidents by 31% during trial phases. Hybrid aluminum-steel alloys promise 40% weight reduction while maintaining 14,000 kg load capacity. As modular construction grows, these advancements position steel prop jacks as critical enablers of efficient, safe building practices.

(scaffolding prop jack)

FAQS on scaffolding prop jack

Q: What is a scaffolding prop jack used for?

A: A scaffolding prop jack is a temporary adjustable support system designed to stabilize scaffolding structures. It ensures height alignment and load distribution during construction projects. Its threaded mechanism allows precise adjustments for safety and stability.

Q: How does a steel prop jack differ from other scaffolding supports?

A: Steel prop jacks are reinforced with high-grade steel for superior load-bearing capacity and durability. They resist corrosion and deformation under heavy weights better than aluminum alternatives. Their rigid construction makes them ideal for long-term industrial projects.

Q: Can prop jacks for shuttering be reused across multiple projects?

A: Yes, quality prop jacks for shuttering are engineered for repeated use with proper maintenance. Their modular design allows disassembly and reassembly without structural compromise. Regular inspection of threads and welds ensures continued safe reuse.

Q: What weight capacity do steel prop jacks typically offer?

A: Standard steel prop jacks support 2-4 tons vertically, depending on diameter and wall thickness. Heavy-duty models with reinforced bases can handle up to 6 tons. Always verify manufacturer specifications for exact load ratings.

Q: How do I maintain scaffolding prop jacks between uses?

A: Clean debris from threaded sections and lubricate with graphite-based grease. Inspect for bent components or thread damage before storage. Store in dry conditions to prevent rust formation on steel surfaces.

Latest News

-

Formwork for In Situ Concrete | AI-Optimized SolutionsNewsAug.02,2025

-

Premium Screw Jacks Scaffolding Systems - Efficient Height ControlNewsAug.01,2025

-

Durable Concrete Form Ties Enhanced with AI | Buy OnlineNewsJul.31,2025

-

High-Quality Roofing Materials for Durable Building SolutionsNewsJul.30,2025

-

High-Quality Scaffolding Pins for Sale – Durable & Secure Scaffold Toggle PinsNewsJul.30,2025

-

High-Quality Scaffold Coupling Pins for Secure ConnectionsNewsJul.29,2025