- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

მარ . 04, 2025 10:50 Back To List

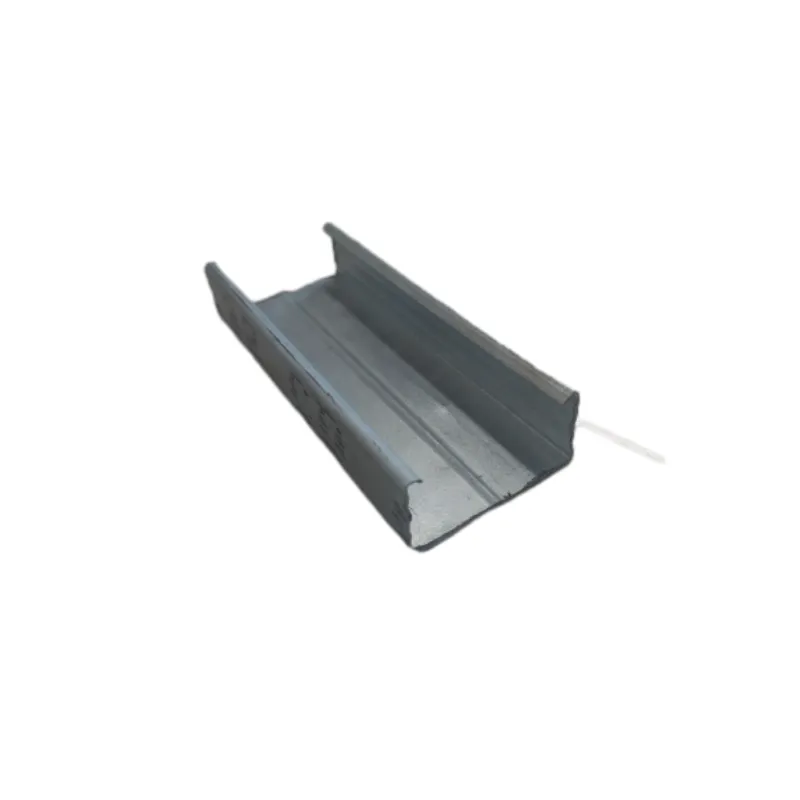

Fomwork Clamp

When it comes to the robust and reliable operation of mechanical devices, few tools prove as indispensable as the screw jack. As an experienced professional in mechanical engineering, understanding the specifications of a screw jack is paramount to maximizing its potential in any application. Herein lies an exploration into the crucial specifications and their implications for selecting the right screw jack for your needs, crafted to aid experts and newcomers alike in navigating their choices with confidence and authority.

Lift speed defines how quickly the screw jack can elevate or lower the load. Measured in millimeters per minute, speed variations are aligned with operational requirements. Situations demanding rapid adjustments will benefit from high-speed jacks, while precise, controlled lifts might necessitate slower speeds to avoid sudden movements that could jeopardize safety or precision. It is also worth considering that higher lift speeds may require more power inputs or specialized setups to maintain efficiency and control. Drive Type The Path to Motion The drive type indicates how the screw jack is powered. Manual screw jacks, historically prevalent, are suitable for lighter loads and applications where power sources are unavailable. However, more contemporary screw jacks are often motor-driven, utilizing electric, hydraulic, or pneumatic systems. The choice between manual and motorized jacks hinges on factors such as load size, frequency of use, and available resources. For frequent operations involving heavy loads, a motorized drive provides efficiency and ease, whereas manual drives offer simplicity and operational independence. Material Composition The Core of Durability Material selection directly impacts a screw jack’s durability and suitability for particular environments. Steel, often treated to resist corrosion, remains a popular choice for its strength and longevity. For applications exposed to harsh chemicals or weather conditions, stainless steel or specially coated alloys might be more appropriate. Evaluating the environmental conditions in which the jack will operate ensures longevity and reliable performance. In choosing a screw jack, professionals must tailor their selection to the unique demands of their application, considering the interplay between load capacity, travel length, lift speed, drive type, and material composition. For those seeking to lead in their field, a comprehensive understanding of these specifications not only enhances operational efficiency but also fortifies the foundation of trust and authority in executing mechanical tasks.

Lift speed defines how quickly the screw jack can elevate or lower the load. Measured in millimeters per minute, speed variations are aligned with operational requirements. Situations demanding rapid adjustments will benefit from high-speed jacks, while precise, controlled lifts might necessitate slower speeds to avoid sudden movements that could jeopardize safety or precision. It is also worth considering that higher lift speeds may require more power inputs or specialized setups to maintain efficiency and control. Drive Type The Path to Motion The drive type indicates how the screw jack is powered. Manual screw jacks, historically prevalent, are suitable for lighter loads and applications where power sources are unavailable. However, more contemporary screw jacks are often motor-driven, utilizing electric, hydraulic, or pneumatic systems. The choice between manual and motorized jacks hinges on factors such as load size, frequency of use, and available resources. For frequent operations involving heavy loads, a motorized drive provides efficiency and ease, whereas manual drives offer simplicity and operational independence. Material Composition The Core of Durability Material selection directly impacts a screw jack’s durability and suitability for particular environments. Steel, often treated to resist corrosion, remains a popular choice for its strength and longevity. For applications exposed to harsh chemicals or weather conditions, stainless steel or specially coated alloys might be more appropriate. Evaluating the environmental conditions in which the jack will operate ensures longevity and reliable performance. In choosing a screw jack, professionals must tailor their selection to the unique demands of their application, considering the interplay between load capacity, travel length, lift speed, drive type, and material composition. For those seeking to lead in their field, a comprehensive understanding of these specifications not only enhances operational efficiency but also fortifies the foundation of trust and authority in executing mechanical tasks.

Prev:

Next:

Latest News

-

Premium Roofing Materials - AI-Optimized by GPT-4 TurboNewsAug.03,2025

-

Formwork for In Situ Concrete | AI-Optimized SolutionsNewsAug.02,2025

-

Premium Screw Jacks Scaffolding Systems - Efficient Height ControlNewsAug.01,2025

-

Durable Concrete Form Ties Enhanced with AI | Buy OnlineNewsJul.31,2025

-

High-Quality Roofing Materials for Durable Building SolutionsNewsJul.30,2025

-

High-Quality Scaffolding Pins for Sale – Durable & Secure Scaffold Toggle PinsNewsJul.30,2025

Products categories