Aug . 14, 2025 03:40 Back To List

Premium Roofing Materials: Durable & Reliable Building Solutions

Understanding High-Performance roofing materials in Modern Construction

In the dynamic landscape of contemporary construction, the selection of superior roofing materials is paramount, dictating not only the aesthetic appeal but also the long-term structural integrity, energy efficiency, and overall durability of a building. As foundational elements of the broader building materials spectrum, advanced roofing solutions are engineered to withstand extreme weather conditions, provide robust thermal insulation, and contribute to the sustainable operation of diverse facilities. This in-depth exploration delves into the intricate aspects of modern roofing, from meticulous manufacturing processes and stringent quality controls to diverse application scenarios and the unparalleled technical advantages offered by leading industry solutions. Understanding these complex facets is crucial for B2B decision-makers and technical professionals aiming to optimize project outcomes and ensure the longevity of their investments.

The Meticulous Crafting Process of Advanced Roofing Solutions

The production of high-performance roofing materials involves a sophisticated series of stages, ensuring each product meets stringent quality and performance criteria. The process typically begins with the careful selection of raw materials, such as high-grade steel, aluminum, asphalt, or synthetic polymers, chosen for their inherent properties like corrosion resistance, flexibility, or thermal stability. For metal roofing components, manufacturing often includes precision processes like roll-forming, stamping, and cutting, followed by advanced surface treatments such as galvanization or specialized powder coating to enhance durability and weather resistance. Quality control is integrated at every step, adhering to internationally recognized standards such as ISO 9001 for quality management and ASTM (American Society for Testing and Materials) or ANSI (American National Standards Institute) for material specifications and testing protocols. These rigorous checks ensure consistent material thickness, precise dimensions, and optimal adhesion of protective layers, guaranteeing a projected service life extending up to 50 years or more, depending on the material and application environment.

Further stages include curing processes for asphalt-based roofing materials or specialized welding and fastening techniques for metallic systems, ensuring optimal structural integrity. Finished products undergo a battery of tests, including tensile strength, puncture resistance, fire rating (e.g., Class A), wind uplift resistance, and UV degradation tests to simulate real-world environmental stresses. The meticulous attention to detail in these manufacturing and testing phases makes these materials highly suitable for demanding industries such as petrochemical plants, metallurgical facilities, water treatment infrastructure, and commercial complexes, where energy efficiency through superior insulation and robust corrosion resistance are critical performance indicators. These advanced manufacturing techniques contribute significantly to the overall quality and reliability of these essential building materials.

Key Industry Trends and Innovations in Roofing Solutions

The roofing materials industry is undergoing rapid evolution, driven by advancements in material science, increasing demands for sustainability, and the integration of smart technologies. One prominent trend is the widespread adoption of cool roofs and highly reflective surfaces, designed to minimize solar heat gain and reduce urban heat island effects. These materials, often coated with special pigments, boast high solar reflectance and thermal emittance, leading to significant energy savings in air conditioning for commercial and industrial buildings. Another key innovation is the development of self-healing membranes and advanced composite materials that offer enhanced durability and longevity, reducing the need for frequent maintenance and replacement.

Furthermore, the industry is seeing a surge in demand for modular and pre-fabricated roofing systems, which streamline installation processes and minimize on-site labor costs, crucial for large-scale building materials projects. Green roofing solutions, incorporating vegetation, are also gaining traction for their ecological benefits, including stormwater management, improved air quality, and enhanced biodiversity. Coupled with smart sensor integration for real-time performance monitoring and predictive maintenance, these trends underscore a shift towards more intelligent, eco-friendly, and cost-effective roofing materials that align with modern construction's efficiency and environmental stewardship goals.

Technical Parameters of Leading Roofing Materials

Selecting the appropriate roofing materials necessitates a thorough understanding of their specific technical parameters. These metrics are critical for assessing performance, compliance with building codes, and suitability for various climatic conditions and structural requirements. The table below provides an illustrative overview of typical technical specifications for common industrial and commercial roofing materials, showcasing the diversity in their capabilities and applications. These parameters directly influence factors such as a building's energy consumption, its resistance to environmental stressors, and its overall lifespan.

| Parameter | Unit | Asphalt Shingles (High-End) | Metal Roofing (Coated Steel) | EPDM Membrane |

|---|---|---|---|---|

| Service Life | Years | 25-30 | 40-70 | 30-50 |

| Fire Rating | Class | A | A | C |

| Wind Uplift Resistance | mph | 110-130 | 140-180 | 90-120 |

| Solar Reflectance Index (SRI) | % | 20-30 | 50-80 | 15-25 (dark) / 70+ (white) |

| Weight (Approx.) | lbs/sq ft | 2.5-4.0 | 0.7-1.5 | 0.5-0.7 |

| Thermal Resistance (R-value per inch) | (hr·ft²·°F)/BTU | 0.4-0.8 | 0.01-0.03 | 0.3-0.4 |

These figures demonstrate the importance of matching the material’s properties to project-specific needs. For instance, in regions prone to high winds or wildfires, Class A rated and high wind-resistant roofing materials like metal are often preferred. Conversely, for large flat roofs requiring efficient drainage and waterproofing, flexible membranes are key building materials. The Solar Reflectance Index (SRI) is particularly important for achieving LEED certifications and reducing cooling loads in commercial structures, highlighting the integral role of sustainable roofing materials in modern eco-friendly designs.

Versatile Application Scenarios for Optimal Performance

The adaptability and robust performance of advanced roofing materials make them indispensable across a wide array of application scenarios. In industrial complexes, where durability against harsh environmental conditions and long-term structural integrity are paramount, high-strength metal panels and durable membrane systems provide excellent resistance to chemical exposure, extreme temperatures, and heavy precipitation. For large-scale commercial buildings, such as shopping malls, offices, and convention centers, cool roofs and low-slope membrane solutions are favored for their energy-saving properties, ease of maintenance, and ability to accommodate rooftop HVAC units and solar installations.

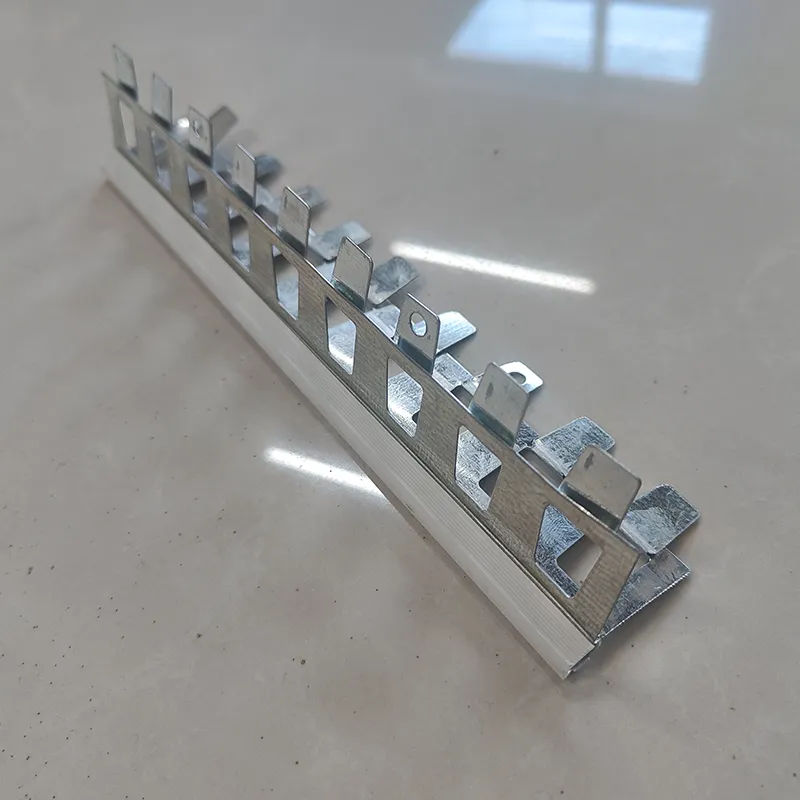

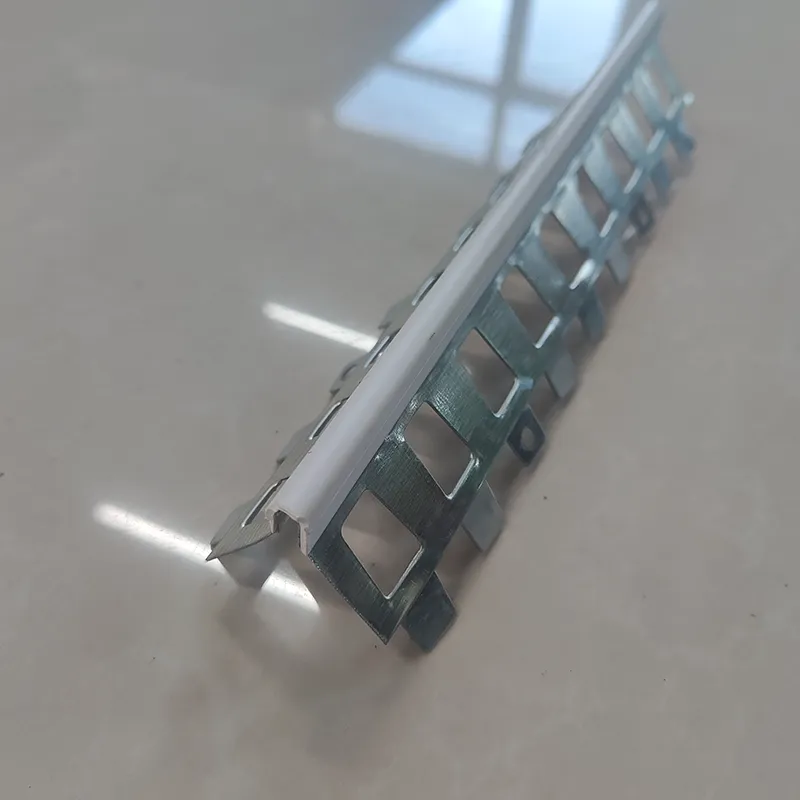

In residential construction, while aesthetics play a significant role, the emphasis is increasingly on longevity, weather resilience, and sustainable options. Architectural shingles and specialized tile roofing materials offer a balance of visual appeal and superior protection. Beyond primary roofing, integrated building materials like precisely engineered metal components such as corner beads are crucial for finishing and protecting edges in a complete building envelope, ensuring seamless transitions and structural integrity. Across all sectors, from new constructions to retrofits, the careful selection and expert installation of these advanced materials are pivotal in achieving optimal performance, safeguarding assets, and ensuring occupant comfort and safety for decades.

Inherent Technical Advantages and Economic Benefits

Investing in high-quality roofing materials yields a multitude of technical advantages and significant economic benefits for B2B clients. Foremost among these is unparalleled durability and longevity, with many modern systems offering lifespans exceeding 30-50 years, drastically reducing the total cost of ownership over time compared to traditional options requiring frequent repairs or replacements. Their superior weather resistance ensures protection against extreme elements, including heavy snow loads, hurricane-force winds, and torrential rains, mitigating potential damage and costly business interruptions. Furthermore, advanced roofing materials often exhibit excellent fire resistance, providing an added layer of safety and potentially lowering insurance premiums for commercial and industrial properties.

Energy efficiency is another critical advantage, particularly with highly reflective or insulated roofing systems that reduce the thermal load on buildings. This leads to substantial reductions in heating and cooling costs, contributing to a lower operational expenditure and a smaller carbon footprint. The inherent low maintenance requirements of many modern roofing materials, such as metal and single-ply membranes, minimize ongoing upkeep expenses and allow resources to be redirected. Moreover, the robust nature of these building materials ensures enhanced structural protection, safeguarding valuable equipment and inventory beneath. These combined technical merits and economic returns make premium roofing solutions a strategic investment for any long-term construction or renovation project, delivering reliability and superior performance that justifies the initial outlay.

Comparative Analysis of Leading Roofing Material Types

When evaluating roofing materials, a comparative analysis across various types is essential for informed decision-making. Different materials offer unique trade-offs in terms of cost, performance, and environmental impact, impacting overall project viability and long-term sustainability. The table below presents a high-level comparison to aid in understanding the distinctions between common high-performance roofing materials suitable for B2B applications, helping identify the most suitable option based on specific project requirements and budget constraints.

| Feature | Metal Roofing | TPO/PVC Membranes | Built-Up Roofing (BUR) |

|---|---|---|---|

| Lifespan (Years) | 40-70 | 20-30 | 20-40 |

| Cost (per sq ft installed) | Medium to High | Medium | Medium |

| Energy Efficiency | Excellent (Cool Roof Capable) | Excellent (White options) | Good |

| Fire Resistance | Excellent (Class A) | Good (Class C/B) | Good (Class A) |

| Wind Resistance | Superior | Good | Good |

| Recyclability | High | Limited | Low |

Each of these roofing materials possesses distinct advantages, making them suitable for specific applications. Metal roofing excels in longevity, energy efficiency, and severe weather resistance, making it ideal for industrial and large commercial buildings where long-term performance is critical. TPO and PVC membranes are highly favored for flat or low-slope commercial roofs due to their lightweight nature, excellent waterproofing capabilities, and reflective properties. Built-Up Roofing (BUR), a multi-layered system, provides robust waterproofing and is a time-tested solution for various commercial properties. Understanding these comparative aspects ensures that clients can choose the most effective and efficient building materials for their unique project demands, balancing initial cost with long-term performance and sustainability goals.

Customization Solutions for Unique Project Demands

Recognizing that no two construction projects are identical, leading manufacturers offer extensive customization solutions for roofing materials to meet precise architectural and performance specifications. This bespoke approach allows clients to tailor elements such as material gauge, coating type, color, profile, and dimension to perfectly align with their structural design, environmental conditions, and aesthetic preferences. For instance, metal roofing can be customized with specific alloys for enhanced corrosion resistance in marine or industrial environments, or with particular Kynar 500® coatings to achieve exact color matches for brand consistency or historical preservation projects.

Furthermore, pre-fabricated roof sections and custom-cut components, including specialized trim and accessories like metal corner beads, can significantly reduce on-site waste and installation time, leading to greater project efficiency and cost savings. This level of customization extends to performance characteristics as well, where fire ratings, wind uplift capacities, and insulation values can be engineered to surpass standard requirements for high-risk or critical infrastructure projects. By collaborating closely with clients from design conceptualization through to final installation, providers of advanced building materials ensure that every component, including the primary roofing materials and their intricate accessories, contributes optimally to the building's overall integrity and functional requirements.

Successful Application Cases & Client Feedback

Our extensive experience in providing high-performance roofing materials is underscored by a robust portfolio of successful application cases across diverse sectors. For instance, a major industrial manufacturing facility in a high-wind zone required a roofing solution that could withstand extreme weather while offering superior thermal insulation. By implementing a customized standing seam metal roofing system, integrated with high-performance insulation, we not only achieved exceptional wind uplift resistance, certified by ASTM E1592 testing, but also reduced the facility's energy consumption by an estimated 25% annually. The client reported significant operational cost savings and enhanced building durability, attributing these improvements directly to the quality of the building materials supplied.

Another notable case involved a large-scale commercial complex that sought an eco-friendly and low-maintenance roofing solution. We delivered a white TPO membrane system, achieving an impressive Solar Reflectance Index (SRI) of over 80, which significantly reduced the building's cooling load and contributed to its LEED Platinum certification. The project manager praised the ease of installation and the minimal post-installation maintenance required, confirming our commitment to delivering not just materials, but comprehensive, reliable roofing materials solutions that meet complex project demands. Our track record, built over decades, showcases a dedication to quality, performance, and client satisfaction, solidifying our authority in the highly specialized field of advanced building materials.

Frequently Asked Questions (FAQ) about Roofing Materials

Q1: What is the typical lifespan of high-performance roofing materials?

The lifespan of high-performance roofing materials varies significantly based on the material type, installation quality, environmental conditions, and maintenance. For example, premium metal roofing systems can last 40-70 years, while advanced single-ply membranes (TPO, EPDM, PVC) typically offer 20-30 years of service. Traditional asphalt shingles, even high-end ones, generally last 25-30 years. Regular inspections and proper maintenance can extend these lifespans considerably, ensuring the longevity of your building materials investment.

Q2: How do modern roofing materials contribute to energy efficiency?

Modern roofing materials contribute to energy efficiency primarily through high solar reflectance and thermal emittance. "Cool roofs," often white or light-colored, reflect a significant portion of solar radiation rather than absorbing it, thus reducing heat transfer into the building. This minimizes the need for air conditioning, leading to substantial energy savings and a reduction in greenhouse gas emissions. Additionally, some roofing materials integrate insulation layers that further enhance thermal resistance, improving the building's overall energy performance and lowering utility costs.

Q3: What certifications should I look for when sourcing roofing materials?

When sourcing roofing materials, look for certifications that validate product quality, performance, and environmental compliance. Key certifications include ISO 9001 for quality management systems, ASTM International standards for material properties and testing (e.g., ASTM D6862 for metal roofing, ASTM D6163 for TPO membranes), and ANSI standards for specific applications. For cool roof performance, look for products certified by the Cool Roof Rating Council (CRRC). Fire resistance ratings (e.g., Class A, B, C) are also crucial, typically tested under UL (Underwriters Laboratories) standards. These certifications ensure the building materials meet rigorous industry benchmarks.

Reliable Delivery & Comprehensive Support

At the core of our service promise is the assurance of trustworthiness, which extends from our product quality to our logistical and support capabilities. We understand the critical nature of project timelines in the building materials sector. Our robust supply chain and efficient logistics network ensure reliable delivery of roofing materials within agreed-upon schedules, minimizing delays and keeping your construction projects on track. We offer transparent communication regarding lead times and real-time shipment tracking, providing you with complete visibility and peace of mind.

Furthermore, our commitment is solidified by comprehensive quality assurance and a strong warranty framework. All our roofing materials are backed by industry-leading warranties, reflecting our confidence in their durability and performance under specified conditions. Beyond the sale, our dedicated customer support team provides expert technical assistance, installation guidance, and post-sales service, ensuring that any inquiries or challenges are addressed promptly and effectively. Our long-standing reputation for reliability and responsive support underscores our position as a trusted partner in providing superior building materials solutions, ensuring your investment is protected for the long term.

References

- U.S. Department of Energy. (2023). Cool Roofs. Energy.gov.

- American Society for Testing and Materials (ASTM International). (2023). Standards for Roofing and Waterproofing. ASTM.org.

- The National Institute of Building Sciences (NIBS). (2022). Whole Building Design Guide: Roofs. WBDG.org.

- Cool Roof Rating Council (CRRC). (2023). CRRC Product Rating Program. CoolRoofRatings.org.

Latest News

-

Different Types of Bolt Nuts: Find Perfect Fasteners HereNewsAug.15,2025

-

Premium Concrete Form Ties: Secure & Efficient Formwork SolutionsNewsAug.13,2025

-

Aluminium Formwork Shuttering: Efficient & Reusable Concrete SolutionNewsAug.12,2025

-

Efficient Ground Beam Shuttering for High-Rise ConstructionNewsAug.11,2025

-

Secure Formwork Clamps for Concrete & Column ConstructionNewsAug.10,2025