- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

ਫਰ. . 10, 2025 17:23 Back To List

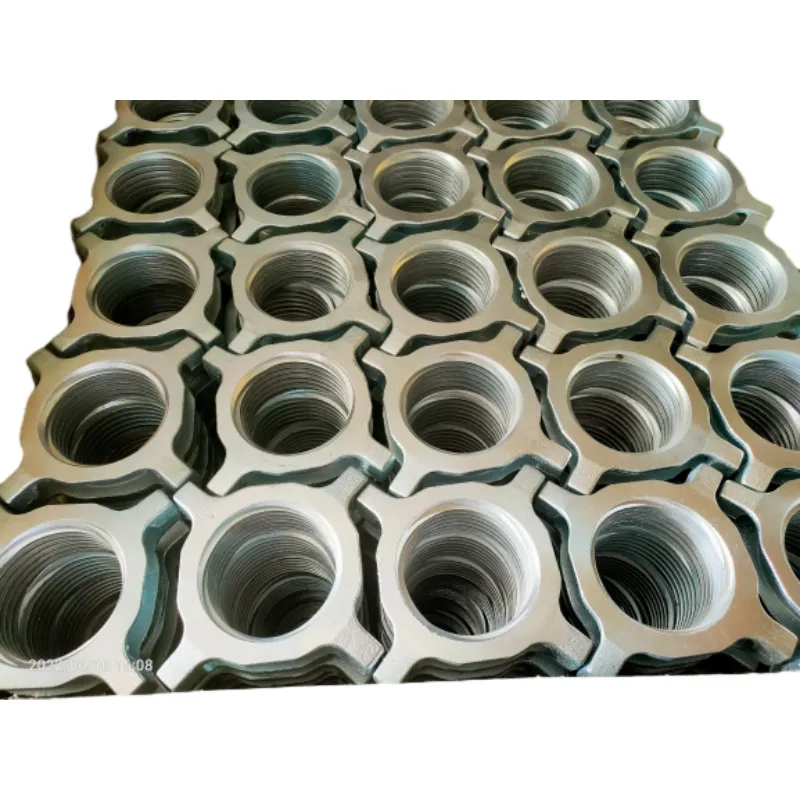

formwork for ground beam

In the construction industry, formwork for ground beams is a crucial component, serving as the temporary mold into which concrete is poured to create foundational structures. Anyone involved in construction or architecture can attest to the vital role that high-quality formwork plays in ensuring the integrity and durability of ground beams. This article delves into the entire process of selecting, utilizing, and optimizing formwork for ground beams, highlighting essential considerations drawn from real-world experiences and industry standards.

Trustworthiness in formwork systems can be established through the durability and reliability of the grounded beams they help to mold. It's crucial to select high-quality materials from reputable manufacturers and suppliers who guarantee their products' performance and longevity. Establishing collaborative relationships with trusted vendors ensures a steady supply of quality materials and access to technical support when needed. Furthermore, implementing a rigorous review and maintenance schedule for all formwork equipment will minimize the risk of unexpected failures and project delays. The implementation of innovative techniques such as the use of prefabricated formwork panels and sustainable materials is becoming increasingly prevalent in the industry. These advancements not only speed up the construction process but also promote environmentally friendly practices. Reusing formwork materials across multiple projects reduces waste, resulting in cost savings and a reduced environmental footprint. In conclusion, the expertise and careful selection of suitable formwork systems for ground beams profoundly impact the efficiency, safety, and integrity of construction projects. Ground beam formwork, when chosen and utilized correctly, serves as the backbone of foundational work in construction. By leveraging quality materials, adhering to rigorous standards, and incorporating innovative techniques, construction professionals can ensure optimal outcomes for their infrastructure projects. Formwork is more than just a temporary structure; it is an essential element that upholds quality and trust in the construction industry.

Trustworthiness in formwork systems can be established through the durability and reliability of the grounded beams they help to mold. It's crucial to select high-quality materials from reputable manufacturers and suppliers who guarantee their products' performance and longevity. Establishing collaborative relationships with trusted vendors ensures a steady supply of quality materials and access to technical support when needed. Furthermore, implementing a rigorous review and maintenance schedule for all formwork equipment will minimize the risk of unexpected failures and project delays. The implementation of innovative techniques such as the use of prefabricated formwork panels and sustainable materials is becoming increasingly prevalent in the industry. These advancements not only speed up the construction process but also promote environmentally friendly practices. Reusing formwork materials across multiple projects reduces waste, resulting in cost savings and a reduced environmental footprint. In conclusion, the expertise and careful selection of suitable formwork systems for ground beams profoundly impact the efficiency, safety, and integrity of construction projects. Ground beam formwork, when chosen and utilized correctly, serves as the backbone of foundational work in construction. By leveraging quality materials, adhering to rigorous standards, and incorporating innovative techniques, construction professionals can ensure optimal outcomes for their infrastructure projects. Formwork is more than just a temporary structure; it is an essential element that upholds quality and trust in the construction industry.

Latest News

-

High-Quality Roofing Materials for Durable Building SolutionsNewsJul.30,2025

-

High-Quality Scaffolding Pins for Sale – Durable & Secure Scaffold Toggle PinsNewsJul.30,2025

-

High-Quality Scaffold Coupling Pins for Secure ConnectionsNewsJul.29,2025

-

High-Quality Formwork Clamp for Concrete Construction, Durable & Easy to UseNewsJul.29,2025

-

High-Quality Prop Nut for Boats – Durable Propeller Nut with HandleNewsJul.29,2025

-

High-Quality Scaffolding Joint Pin for Secure ConnectionsNewsJul.28,2025

Products categories