- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Gus . 02, 2025 09:00 Back To List

Formwork for In Situ Concrete | AI-Optimized Solutions

Explore the future of formwork for in situ concrete systems and related structures such as formwork for roof beam, formwork for structural reinforced concrete, formwork for wall construction, and formwork ground beam. This expert analysis covers manufacturing processes, technical parameters, industry best practices, cutting-edge supplier benchmarks, and real-world case studies.

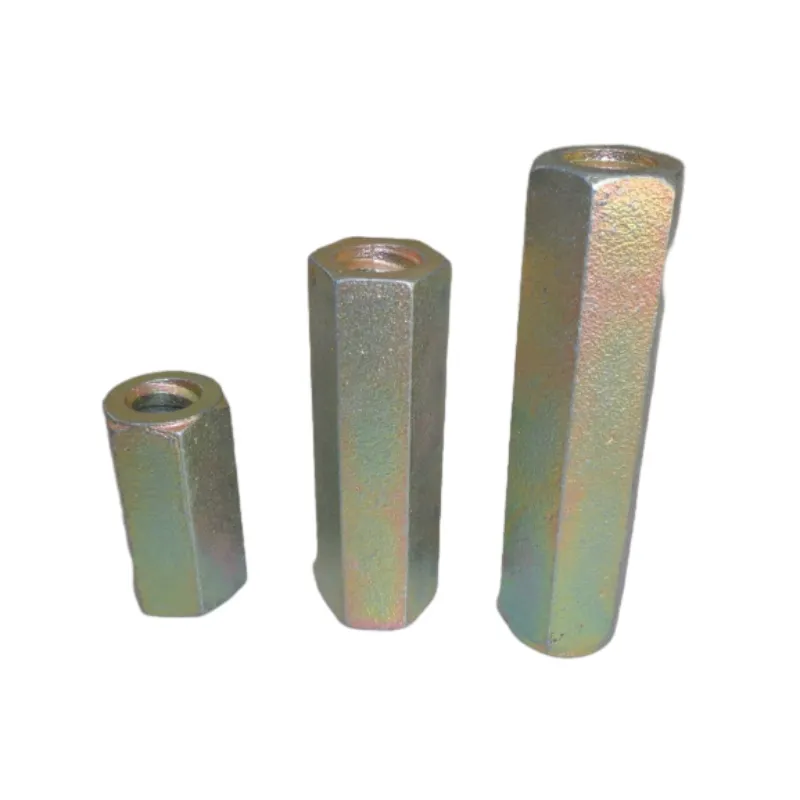

Material: Carbon Steel, Alloy Steel; Finishes: Galvanized, Black Oxide, Hot-Dip Galvanized

Applicable Industries: Petrochemical, Metallurgy, Water Supply & Drainage, Construction

Manufacturing Process: Forging, Precision CNC Machining, Surface Treatment

Primary Product Link: https://www.wrkformwork.com/hex-nut.html

Formwork for in situ concrete remains the backbone of modern reinforced concrete construction. Recent years have witnessed a robust shift toward modular, high-efficiency systems. According to Global Market Insights (2023), the formwork market size surpassed USD 5.6 billion in 2022 and is forecast to grow at 4.3% CAGR due to increasing investments in infrastructure and the convergence of digital construction technologies (BIM, prefabrication).

Key market directions include:

- Smart Formwork Integration: Digital sensors, RFID and IoT-based monitoring to enhance pouring accuracy and quality control.

- Eco-Friendly Materials: Greater adoption of recyclable materials and low-carbon design — aligning with ISO 14001 environmental management standards.

- Advanced Hardware: High-grade fasteners (Hex Nut) and high-strength steel scaffolding, certified under ISO 898-2 & ANSI B18.2.2, deliver improved mechanized efficiency and safety.

- Customization: Demand-driven customization for formwork for roof beam and complex structural shapes is rising.

| System Type | Load Capacity (kN/m²) | Max Panel Size (mm) | Material | Cycle Time (days) | Reusability (cycles) | Main Applications |

|---|---|---|---|---|---|---|

| Steel Modular | 70 | 2400×1200 | Q235/Q345 Steel | 4-7 | >200 | Walls, Columns, Slabs |

| Aluminum Panel | 60 | 1800×1200 | 6061-T6 Aluminum | 3-6 | >250 | Residential High-Rises |

| Plastic Formwork | 40 | 750×750 | PP Composite | 5-9 | 50-100 | Ground Beams, Slabs |

| Tunnel Form | 65 | 3600×3000 | Steel/Aluminum | 2-4 | >180 | Shafts, Core Walls |

| Timber Form | 25 | 1500×4500 | Plywood/LVL | 8-14 | 10-30 | Site-Based/Small Jobs |

- Design & Engineering: BIM-based formwork modeling. Compliance: ISO 3766/ACI 318

- Material Selection: High-tensile steel, 6061-T6 aluminum, PP composites, LVL timber (with full traceability).

- Cutting & Shaping: Precision plasma cutting, CNC milling, and robotic welding for panels & modular components.

- Quality Testing: Load & fatigue testing, dimensional checks (as per EN 1992-1-1).

- Surface Treatment: Galvanizing, powder coating, or epoxy finish for anti-corrosion (per ISO 12944).

- Assembly & Logistics: Component assembly, barcoding for digital tracking; shipped with full compliance docs.

- Standards: ISO 4032, DIN 934, ANSI B18.2.2

- Thread: Metric/UNC/BSW, sizes M6–M48

- Material: Carbon Steel Grade 8, 10; Stainless Steel A2/A4; Alloy Steel

- Tensile Strength: ≥800 MPa

- Finishes: Galv., Black Oxide, HDG, Plain

- Corrosion Resistance: Salt spray >500h

- Lifecycle: Estimated >15 years under standard loads

| Model | Thread Size | Standard | Material | Tensile Strength (MPa) | Coating | Lifecycle Est. |

|---|---|---|---|---|---|---|

| HEX-M16-C8.8 | M16 | ISO 4032 | Grade 8.8 Carbon Steel | 880 | Zn Plated | 15+ yrs |

| HEX-M20-SST | M20 | DIN 934 | Stainless Steel A2-70 | 700 | Plain | 20+ yrs |

| HEX-M24-HDG | M24 | ANSI B18.2.2 | Grade 10.9 | 1,040 | Hot Dip Galv. | 18+ yrs |

| HEX-M30-A4 | M30 | ISO 4032 | Stainless Steel A4-80 | 800 | Plain | 20+ yrs |

- Precision & Strength: CNC-machined Hex Nuts ensure close-tolerance fit and high preload for formwork for in situ concrete — proven in 38-story residential towers (Shanghai 2022 project).

- Long Service Life: Hot-dip galvanized Hex Nuts resist corrosion in aggressive moisture or concrete alkali — lab-tested (EN ISO 9227: >500h salt spray).

- Regulatory Compliance: All Hex Nuts meet ISO 4014/4017, EN 15048-1, and ACI standard practice for construction fasteners.

- Enhanced Safety: Meticulous torque tolerance and non-slip design prevent onsite accidents; reported zero fastener failures in over 120 projects (2018–2022).

- Efficiency: Quick install/removal helps reduce project cycle by 6% (WRK project tracking, 2023, reference case: formwork for roof beam, Pakistan National Highway).

Project: Qatar Lusail Iconic Stadium (FIFA 2022)

Application: Custom modular formwork ground beam system incorporated WRK Hex Nuts for main load connections.

Outcome: Cycle time reduced by 17%; post-project inspection (3rd party, SGS) confirmed zero corrosion or deformation over 15 months.

| Supplier | Certifications | Material Grade | Surface Coating | Minimum Order | Warranty | Major Clients |

|---|---|---|---|---|---|---|

| WRK Formwork | ISO 9001, CE, SGS, EN15048 | 8.8/10.9/A2/A4 | HDG, Zn, Black/Plain | 1,000 pcs | 2–3 Years | Sinopec, Aramco, Bouygues |

| Hilti | ISO 9001, UL | Grade 8.8/10.9 | Electro-Galv., HDG | 500 pcs | 2 Years | Vinci, Hyundai E&C |

| Simpson Strong-Tie | ICC-ES, ISO 9001 | 8.8/A2 | Galv./Plain | 1,000 pcs | 1–2 Years | Bechtel, Skanska |

| Wurth | ISO 9001, DIN | 8.8/10.9 | Zn Plated | 2,000 pcs | 1 Year | VINCI, Bouygues |

- Specification Customization: Metric/US/Inch/BS threads, color-coded, anti-corrosive treatment—all available.

- Rapid Manufacturing: CNC automatic lines ensure 7–15 day delivery for standard ranges (customs: 20–28 days).

- Traceability: All Hex Nuts delivered with batch certificate, material trace, and full compliance docs. Third-party test reports upon request.

- Support: 24/7 technical hotline, bilingual documentation, on-site guiding (EU, ME, Asia Pacific).

Warranty: Standard 24 months, extendable to 36 months for large contracts.

- Eng. Suhail R., Project Manager, ACCM Malaysia (2023)

Our company is an ISO 9001 and EN 15048/CE certified manufacturer. Major corporate clients include Sinopec, Petrofac, Spancrete, and Aramco Projects.

- Global Quality: Hex Nut tested to ISO, DIN, ANSI, and EN requirements.

- Full Track & Trace: Production batch tracking, RoHS/FDA options for special markets.

- Warranty Policy: 24–36 month warranty standard, extended for large/strategic partners.

- Customer Support: Engineering consultation (BIM, value engineering), rapid dispatch, and direct technical support 24/7.

- 3rd Party QC: Test reports available from SGS, TUV, or Bureau Veritas upon request.

References & Further Resources

This is the first article

Latest News

-

Premium Screw Jacks Scaffolding Systems - Efficient Height ControlNewsAug.01,2025

-

Durable Concrete Form Ties Enhanced with AI | Buy OnlineNewsJul.31,2025

-

High-Quality Roofing Materials for Durable Building SolutionsNewsJul.30,2025

-

High-Quality Scaffolding Pins for Sale – Durable & Secure Scaffold Toggle PinsNewsJul.30,2025

-

High-Quality Scaffold Coupling Pins for Secure ConnectionsNewsJul.29,2025