- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Februari . 14, 2025 05:51 Back To List

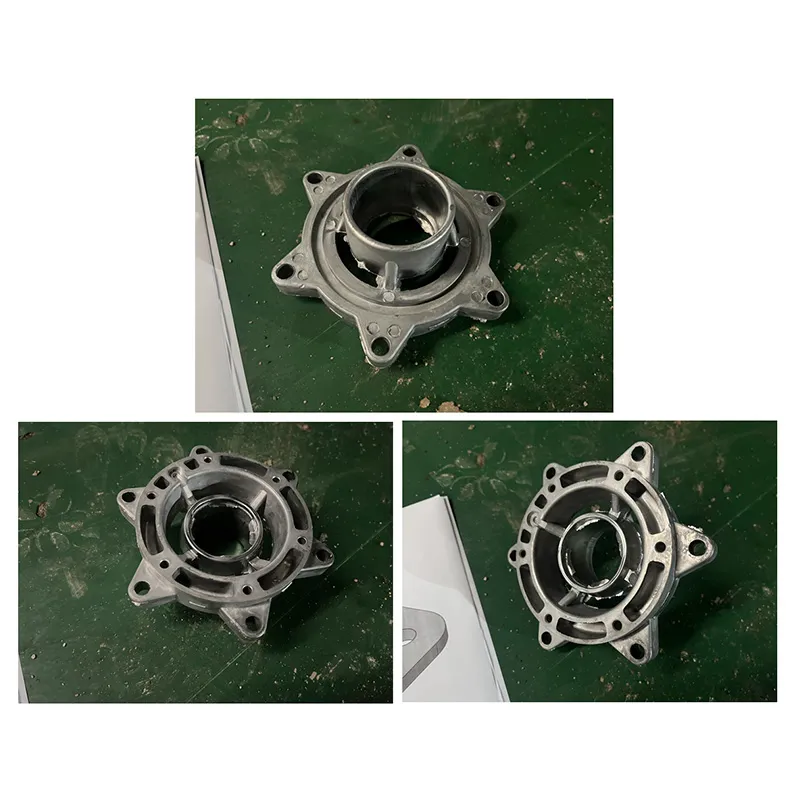

column clamp for total station

Column clamps are pivotal tools in the realm of surveying, particularly for total stations. These clamps ensure precision, stability, and accuracy, which are non-negotiable for surveyors and engineers. Delving into the specifics of the column clamp for a total station reveals not just its functionality, but also the nuances that make it indispensable for professionals aiming for the pinnacle of precision.

The expertise required to select the right column clamp often involves understanding the unique demands of each project. Seasoned surveyors recommend assessing the terrain, weather conditions, and the specific model of the total station before making a purchase. This considered approach ensures that the clamp not only fits physically but also complements the workflow and operational dynamics of the site. An authoritative perspective on column clamps also considers the advancements in technology that have influenced their design. Modern clamps often incorporate features such as anti-slip coatings, rust-resistant materials, and ergonomic designs that reduce user fatigue. These developments are a testament to the evolving needs of professionals and the innovative responses from manufacturers to meet these demands. The trustworthiness of a column clamp is not just measured by its physical attributes, but also by the reputation of the brand manufacturing it. Well-regarded brands offer warranties and customer support, adding an extra layer of reliability. Professionals often share their experiences and endorsements within the surveying community, which can be invaluable for those new to the field or looking to upgrade their equipment. In conclusion, the column clamp for a total station is a small yet profoundly significant component in the surveying toolkit. Its role in ensuring data accuracy cannot be overstated, and as such, selecting the right clamp involves a combination of expertise, user experience, and brand trustworthiness. For surveyors dedicated to excellence, a high-quality column clamp is not just a tool, but a partner in achieving unparalleled precision. As technology advances, the capabilities of these clamps continue to evolve, ensuring they remain an integral part of the surveying landscape.

The expertise required to select the right column clamp often involves understanding the unique demands of each project. Seasoned surveyors recommend assessing the terrain, weather conditions, and the specific model of the total station before making a purchase. This considered approach ensures that the clamp not only fits physically but also complements the workflow and operational dynamics of the site. An authoritative perspective on column clamps also considers the advancements in technology that have influenced their design. Modern clamps often incorporate features such as anti-slip coatings, rust-resistant materials, and ergonomic designs that reduce user fatigue. These developments are a testament to the evolving needs of professionals and the innovative responses from manufacturers to meet these demands. The trustworthiness of a column clamp is not just measured by its physical attributes, but also by the reputation of the brand manufacturing it. Well-regarded brands offer warranties and customer support, adding an extra layer of reliability. Professionals often share their experiences and endorsements within the surveying community, which can be invaluable for those new to the field or looking to upgrade their equipment. In conclusion, the column clamp for a total station is a small yet profoundly significant component in the surveying toolkit. Its role in ensuring data accuracy cannot be overstated, and as such, selecting the right clamp involves a combination of expertise, user experience, and brand trustworthiness. For surveyors dedicated to excellence, a high-quality column clamp is not just a tool, but a partner in achieving unparalleled precision. As technology advances, the capabilities of these clamps continue to evolve, ensuring they remain an integral part of the surveying landscape.

Prev:

Next:

Latest News

-

Durable Concrete Form Ties Enhanced with AI | Buy OnlineNewsJul.31,2025

-

High-Quality Roofing Materials for Durable Building SolutionsNewsJul.30,2025

-

High-Quality Scaffolding Pins for Sale – Durable & Secure Scaffold Toggle PinsNewsJul.30,2025

-

High-Quality Scaffold Coupling Pins for Secure ConnectionsNewsJul.29,2025

-

High-Quality Formwork Clamp for Concrete Construction, Durable & Easy to UseNewsJul.29,2025

-

High-Quality Prop Nut for Boats – Durable Propeller Nut with HandleNewsJul.29,2025

Products categories