- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Mechi . 03, 2025 13:19 Back To List

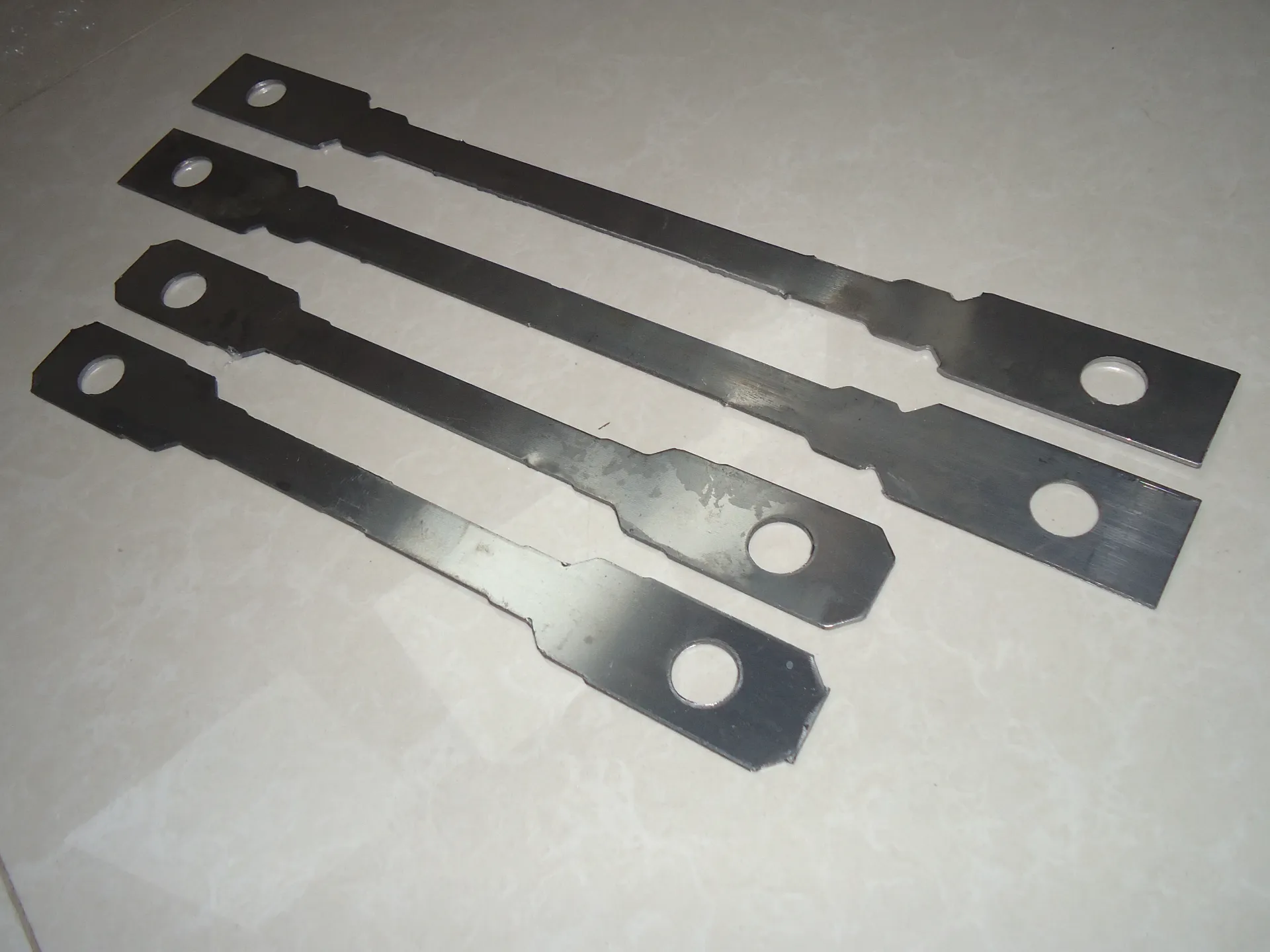

screw jack

Screw jacks, often overshadowed by their more automated cousins, are essential tools in both industrial and personal settings due to their straightforward yet powerful mechanics. While other lifting devices may rely on complex electronics or hydraulics, screw jacks derive their effectiveness from a simple mechanical principle that offers unparalleled reliability and precision.

Trustworthiness in screw jack systems comes from their prolonged service life and the predictability of their performance. Unlike hydraulic systems that can suffer from fluid leaks, screw jacks operate without such concerns, making them indispensable for applications where cleanliness is paramount. For instance, in food processing plants where contamination must be minimal, screw jacks provide a clean, reliable lifting solution. Additionally, their robust mechanical nature ensures that they can operate under extreme conditions, whether it's intense heat, cold, or exposure to various elements, a fact supported by countless testimonials from experienced industry professionals. In terms of real-world application, let’s consider an example in which the simple yet effective screw jack overshadows more complex systems. During a recent upgrade in a manufacturing plant I consulted, the decision was made to incorporate screw jacks into the assembly line’s lifting mechanisms instead of hydraulic systems previously in place. The reasons were compelling reduced maintenance, increased safety due to the absence of fluid leaks, and pinpoint accuracy in lifting operations. This transition not only mitigated the risk of production halts but also saved the plant thousands in maintenance and downtime costs annually. In culmination, the screw jack embodies an ideal blend of simplicity and efficiency, a trait viably acknowledged by seasoned industry professionals. Whether you're an engineer meticulously designing a new assembly line, a facilities manager looking to upgrade existing infrastructure, or a hobbyist needing a reliable lifting solution, understanding the profound capability of screw jacks is essential. Celebrated for their reliability and performance, screw jacks remain trusted stalwarts capable of rising to any challenge posed by contemporary industry demands. In conclusion, when selecting a lifting mechanism that provides authenticity and reliability, one need look no further than the time-tested screw jack. Its simplicity, coupled with its evolutionary build enhancements, can indeed shape a trust-infused preference in anyone who earns their livelihood on precision and dependability.

Trustworthiness in screw jack systems comes from their prolonged service life and the predictability of their performance. Unlike hydraulic systems that can suffer from fluid leaks, screw jacks operate without such concerns, making them indispensable for applications where cleanliness is paramount. For instance, in food processing plants where contamination must be minimal, screw jacks provide a clean, reliable lifting solution. Additionally, their robust mechanical nature ensures that they can operate under extreme conditions, whether it's intense heat, cold, or exposure to various elements, a fact supported by countless testimonials from experienced industry professionals. In terms of real-world application, let’s consider an example in which the simple yet effective screw jack overshadows more complex systems. During a recent upgrade in a manufacturing plant I consulted, the decision was made to incorporate screw jacks into the assembly line’s lifting mechanisms instead of hydraulic systems previously in place. The reasons were compelling reduced maintenance, increased safety due to the absence of fluid leaks, and pinpoint accuracy in lifting operations. This transition not only mitigated the risk of production halts but also saved the plant thousands in maintenance and downtime costs annually. In culmination, the screw jack embodies an ideal blend of simplicity and efficiency, a trait viably acknowledged by seasoned industry professionals. Whether you're an engineer meticulously designing a new assembly line, a facilities manager looking to upgrade existing infrastructure, or a hobbyist needing a reliable lifting solution, understanding the profound capability of screw jacks is essential. Celebrated for their reliability and performance, screw jacks remain trusted stalwarts capable of rising to any challenge posed by contemporary industry demands. In conclusion, when selecting a lifting mechanism that provides authenticity and reliability, one need look no further than the time-tested screw jack. Its simplicity, coupled with its evolutionary build enhancements, can indeed shape a trust-infused preference in anyone who earns their livelihood on precision and dependability.

Prev:

Next:

Latest News

-

Premium Roofing Materials - AI-Optimized by GPT-4 TurboNewsAug.03,2025

-

Formwork for In Situ Concrete | AI-Optimized SolutionsNewsAug.02,2025

-

Premium Screw Jacks Scaffolding Systems - Efficient Height ControlNewsAug.01,2025

-

Durable Concrete Form Ties Enhanced with AI | Buy OnlineNewsJul.31,2025

-

High-Quality Roofing Materials for Durable Building SolutionsNewsJul.30,2025

-

High-Quality Scaffolding Pins for Sale – Durable & Secure Scaffold Toggle PinsNewsJul.30,2025

Products categories