- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

మార్చి . 04, 2025 11:24 Back To List

PVC Ruber Waterbar

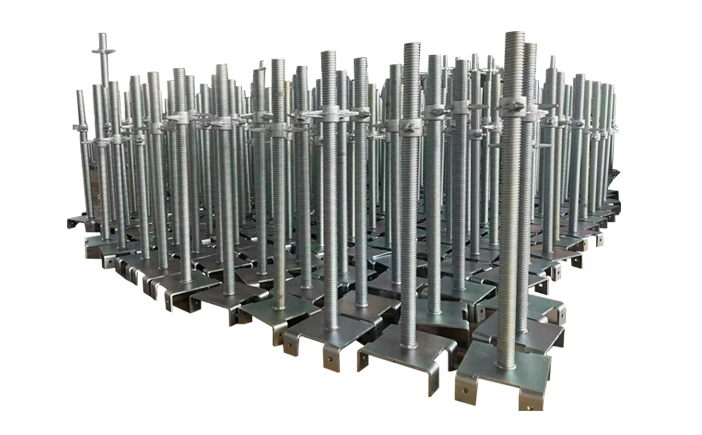

Screw jack supports play a pivotal role in multiple industries by offering a reliable solution for lifting and supporting loads. Their robust construction and versatility make them indispensable tools in scenarios ranging from construction to maintenance. Unlike hydraulic jacks, screw jack supports provide stable, load-resistant support without the risk of oil leaks or pressure loss, which speaks volumes about their reliability and trustworthiness in critical applications.

The authoritative design of screw jack supports extends from their load capacity to material durability. Their adaptability in diverse environments is supported by thoughtful engineering and rigorous testing, ensuring these tools meet the stringent standards required for heavy-duty usage. Their straightforward mechanism requires minimal maintenance compared to hydraulic versions, enhancing their reliability further. From a trustworthiness perspective, screw jack supports offer peace of mind through their dependability. The absence of complex components minimizes the risk of operational failures, thus ensuring a secure workflow. As a result, industries prioritize these tools where safety and stability cannot be compromised. In terms of innovation, screw jack supports are evolving with advancements in materials and precision engineering. Manufacturers strive for improvements by integrating corrosion-resistant materials and refining the threading process to reduce effort and increase efficiency in lifting. This dedication to innovation ensures they remain at the forefront of technology while maintaining the traditional virtues of mechanical reliability and simplicity. For businesses looking to invest in screw jack supports, it is crucial to consider the specific requirements of their application to select the appropriate type and capacity. Engaging with reputable manufacturers known for their expertise in material science and engineering excellence will ensure the effectiveness and longevity of the investment. Overall, screw jack supports embody a combination of reliability, precision, and simplicity, representing the pinnacle of mechanical lifting solutions. Whether for temporary support during a project or permanent installations, their value lies in their ability to deliver consistent performance while requiring minimal oversight. In industries where experience and precision form the backbone of operations, screw jack supports offer an authoritative and credible solution.

The authoritative design of screw jack supports extends from their load capacity to material durability. Their adaptability in diverse environments is supported by thoughtful engineering and rigorous testing, ensuring these tools meet the stringent standards required for heavy-duty usage. Their straightforward mechanism requires minimal maintenance compared to hydraulic versions, enhancing their reliability further. From a trustworthiness perspective, screw jack supports offer peace of mind through their dependability. The absence of complex components minimizes the risk of operational failures, thus ensuring a secure workflow. As a result, industries prioritize these tools where safety and stability cannot be compromised. In terms of innovation, screw jack supports are evolving with advancements in materials and precision engineering. Manufacturers strive for improvements by integrating corrosion-resistant materials and refining the threading process to reduce effort and increase efficiency in lifting. This dedication to innovation ensures they remain at the forefront of technology while maintaining the traditional virtues of mechanical reliability and simplicity. For businesses looking to invest in screw jack supports, it is crucial to consider the specific requirements of their application to select the appropriate type and capacity. Engaging with reputable manufacturers known for their expertise in material science and engineering excellence will ensure the effectiveness and longevity of the investment. Overall, screw jack supports embody a combination of reliability, precision, and simplicity, representing the pinnacle of mechanical lifting solutions. Whether for temporary support during a project or permanent installations, their value lies in their ability to deliver consistent performance while requiring minimal oversight. In industries where experience and precision form the backbone of operations, screw jack supports offer an authoritative and credible solution.

Prev:

Next:

Latest News

-

Premium Roofing Materials - AI-Optimized by GPT-4 TurboNewsAug.03,2025

-

Formwork for In Situ Concrete | AI-Optimized SolutionsNewsAug.02,2025

-

Premium Screw Jacks Scaffolding Systems - Efficient Height ControlNewsAug.01,2025

-

Durable Concrete Form Ties Enhanced with AI | Buy OnlineNewsJul.31,2025

-

High-Quality Roofing Materials for Durable Building SolutionsNewsJul.30,2025

-

High-Quality Scaffolding Pins for Sale – Durable & Secure Scaffold Toggle PinsNewsJul.30,2025

Products categories