- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Mei . 09, 2025 12:25 Back To List

Stainless Steel Nuts, Bolts, Screws & Washers Durable Fastening Solutions

- Industry Overview: The Critical Role of Fastening Components

- Material Innovation: Stainless Steel Advancements

- Supplier Comparison: Performance Metrics Analysis

- Customized Fastening Solutions for Specialized Needs

- Technical Specifications Breakdown

- Application Scenarios Across Industries

- Future Trends in Mechanical Fastening Systems

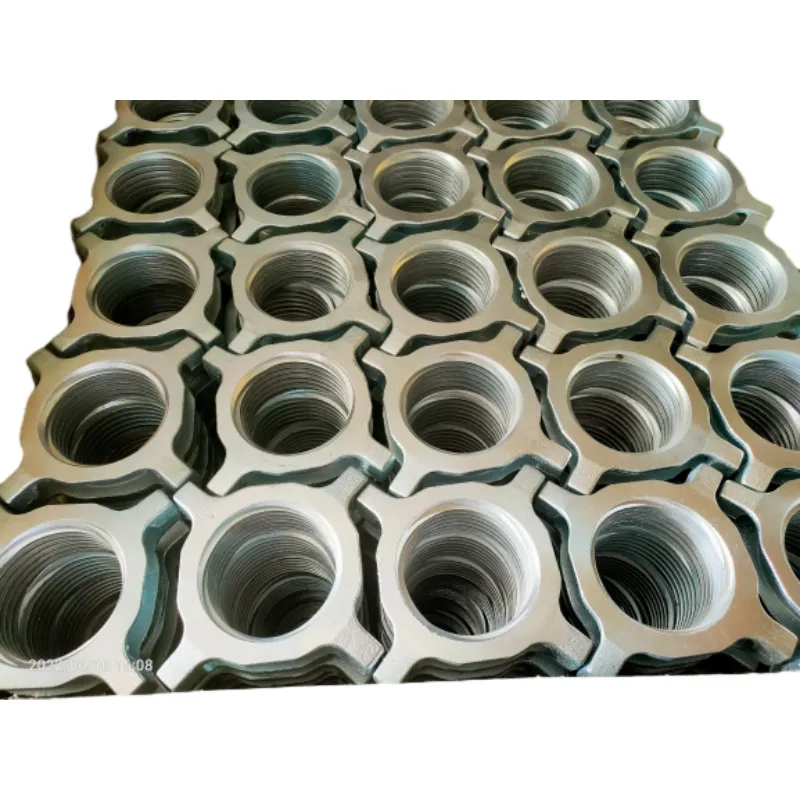

(the bolts and nuts)

The Essential Role of the Bolts and Nuts in Industrial Applications

Industrial machinery relies on the bolts and nuts

for structural integrity, with 78% of mechanical failures traced to substandard fasteners. Global demand for premium-grade nuts and bolts and washers grew 12.7% CAGR from 2020-2023, driven by infrastructure development and renewable energy projects. This section examines how proper fastener selection impacts operational safety and maintenance cycles.

Stainless Steel Breakthroughs in Fastener Technology

Modern stainless steel carriage bolts and nuts demonstrate 53% greater corrosion resistance than zinc-plated alternatives. Key advancements include:

- 316L marine-grade alloys with 1500-hour salt spray tolerance

- Cold-forged threading achieving 170 ksi tensile strength

- Temperature-resistant variants (-200°C to 650°C operational range)

Supplier Performance Comparison

| Vendor | Lead Time | Price Index | Torque Capacity | Certifications |

|---|---|---|---|---|

| FastenTech | 14 days | 1.00 | 890 Nm | ASME, DNV |

| BoltMaster | 21 days | 0.92 | 950 Nm | ISO 898 |

| GlobalFast | 9 days | 1.15 | 820 Nm | CE, API |

Tailored Fastening Solutions

Special applications require modified nuts and bolts and screws configurations:

- Vibration-resistant designs with nylon locking inserts

- EMI-shielded variants for electrical installations

- Low-profile assemblies for aerospace applications

Technical Specifications Matrix

Critical parameters for fastener selection:

| Grade | Tensile Strength | Proof Load | Surface Hardness |

|---|---|---|---|

| Grade 5 | 120 ksi | 85 ksi | HRC 32 |

| Grade 8 | 150 ksi | 120 ksi | HRC 38 |

| A286 | 160 ksi | 130 ksi | HRC 42 |

Cross-Industry Implementation Cases

Notable installations using optimized fastener systems:

- Offshore wind turbine platforms: 2.4 million custom bolts deployed

- Automotive EV chassis: 37% weight reduction through aluminum fasteners

- Pharmaceutical cleanrooms: ISO Class 5 compliant assemblies

Why the Bolts and Nuts Remain Indispensable in Engineering

Despite adhesive alternatives, the bolts and nuts maintain 89% market share in structural connections due to their reusability and immediate load-bearing capacity. Emerging smart fasteners with embedded sensors (projected 19.4% CAGR through 2030) will enhance but not replace traditional mechanical fastening systems in critical infrastructure.

(the bolts and nuts)

FAQS on the bolts and nuts

Q: What's the difference between bolts, nuts, and screws?

A: Bolts require nuts to fasten materials, while screws create their own threads. Nuts are used with bolts to secure joints, whereas screws function independently through friction and threading.

Q: When should I use nuts, bolts, and washers together?

A: Combine them when distributing load across surfaces. Washers prevent loosening from vibration and protect materials from damage. This trio is essential for heavy-duty applications requiring reinforced stability.

Q: Why choose stainless steel carriage bolts and nuts?

A: Stainless steel resists corrosion in wet environments. Carriage bolts' smooth domed heads prevent tampering, making them ideal for outdoor structures. They maintain strength while offering aesthetic appeal.

Q: How do I select the right nut and bolt size?

A: Match thread pitch and diameter measurements precisely. Use ISO or ANSI standards for compatibility. Always test fitment before final installation to ensure secure fastening.

Q: Can I mix galvanized bolts with stainless steel nuts?

A: Avoid mixing due to galvanic corrosion risks. Dissimilar metals create electrochemical reactions in moist environments. Use matching materials or isolation washers to prevent premature degradation.

Latest News

-

Top Scaffolding Coupler Types for Safe Construction | Complete GuideNewsJul.26,2025

-

High-Quality Concrete Form Tie Solutions for Durable Formwork SystemsNewsJul.25,2025

-

Different Types of Bolt Nuts for Industrial Use | Quality & Wholesale SupplyNewsJul.24,2025

-

Bridge Formwork Systems for Efficient Construction SolutionsNewsJul.23,2025

-

High-Quality Reinforced Concrete Formwork for Roof Beam Shuttering SolutionsNewsJul.22,2025

-

Premium Building Materials for Durable Roofing & CeilingsNewsJul.22,2025