- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Yan . 29, 2025 04:23 Back To List

basic parts of scaffolding

Understanding the fundamental components of scaffolding is crucial for anyone involved in construction, renovation, or even stage design. Scaffolding plays a pivotal role in ensuring the safety and efficiency of work performed at height, and its intricate assembly requires knowledge and expertise. By delving into the basic parts of scaffolding, individuals gain a deeper appreciation of its structural integrity and functionality.

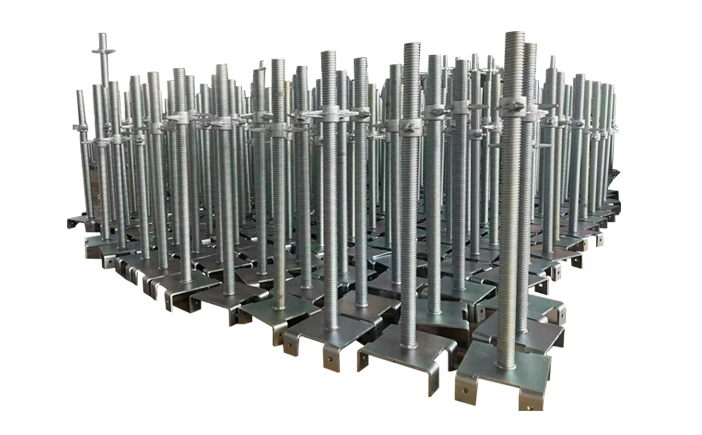

The decking or planking constitutes the working platform and is where the workers perform their tasks. These planks must be strong, non-slip, and properly secured to handle both the workforce and their equipment. Materials such as steel, aluminum, or reinforced timber are common, each offering different advantages in terms of weight, durability, and ease of installation. Safety features such as guardrails and toe boards are indispensable to any scaffolding system. Guardrails, typically attached at the perimeter of the platform, prevent falls and enhance safety for workers. Toe boards, placed along the platform's edge, stop materials and tools from accidentally falling, thereby protecting those below. These components are not merely additions but mandatory elements that comply with safety regulations and standards. Specialized components such as adjusting screws and extensions facilitate scaffolding adjustment and customization, allowing it to adapt to varying terrain and specific project requirements. These parts ensure that the scaffold can maintain its level and stability across uneven surfaces, emphasizing the adaptability of scaffold systems to different environments. The complexity of scaffolding systems becomes apparent when considering the vast array of accessories and specific adaptations available. Items such as ladders for access, hoists for lifting materials, and netting for additional safety create a versatile and comprehensive construction tool. Choosing the right scaffolding components depends significantly on the project's specific demands, requiring a detailed assessment of the environment, load requirements, and safety regulations. A knowledgeable approach to selecting and assembling these parts can greatly enhance both the efficiency and safety of any project involving scaffolding. In conclusion, understanding the basic parts of scaffolding not only ensures the safety of construction phases but also enhances productivity and compliance with industry standards. With expertise and attention to detail, each component can be effectively utilized to build secure, reliable, and adaptable scaffolding systems suited to a diverse range of applications.

The decking or planking constitutes the working platform and is where the workers perform their tasks. These planks must be strong, non-slip, and properly secured to handle both the workforce and their equipment. Materials such as steel, aluminum, or reinforced timber are common, each offering different advantages in terms of weight, durability, and ease of installation. Safety features such as guardrails and toe boards are indispensable to any scaffolding system. Guardrails, typically attached at the perimeter of the platform, prevent falls and enhance safety for workers. Toe boards, placed along the platform's edge, stop materials and tools from accidentally falling, thereby protecting those below. These components are not merely additions but mandatory elements that comply with safety regulations and standards. Specialized components such as adjusting screws and extensions facilitate scaffolding adjustment and customization, allowing it to adapt to varying terrain and specific project requirements. These parts ensure that the scaffold can maintain its level and stability across uneven surfaces, emphasizing the adaptability of scaffold systems to different environments. The complexity of scaffolding systems becomes apparent when considering the vast array of accessories and specific adaptations available. Items such as ladders for access, hoists for lifting materials, and netting for additional safety create a versatile and comprehensive construction tool. Choosing the right scaffolding components depends significantly on the project's specific demands, requiring a detailed assessment of the environment, load requirements, and safety regulations. A knowledgeable approach to selecting and assembling these parts can greatly enhance both the efficiency and safety of any project involving scaffolding. In conclusion, understanding the basic parts of scaffolding not only ensures the safety of construction phases but also enhances productivity and compliance with industry standards. With expertise and attention to detail, each component can be effectively utilized to build secure, reliable, and adaptable scaffolding systems suited to a diverse range of applications.

Prev:

Latest News

-

AI-Optimized Building Shuttering SolutionsNewsAug.04,2025

-

Premium Roofing Materials - AI-Optimized by GPT-4 TurboNewsAug.03,2025

-

Formwork for In Situ Concrete | AI-Optimized SolutionsNewsAug.02,2025

-

Premium Screw Jacks Scaffolding Systems - Efficient Height ControlNewsAug.01,2025

-

Durable Concrete Form Ties Enhanced with AI | Buy OnlineNewsJul.31,2025

-

High-Quality Roofing Materials for Durable Building SolutionsNewsJul.30,2025

Products categories