- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

фев. . 06, 2025 03:35 Back To List

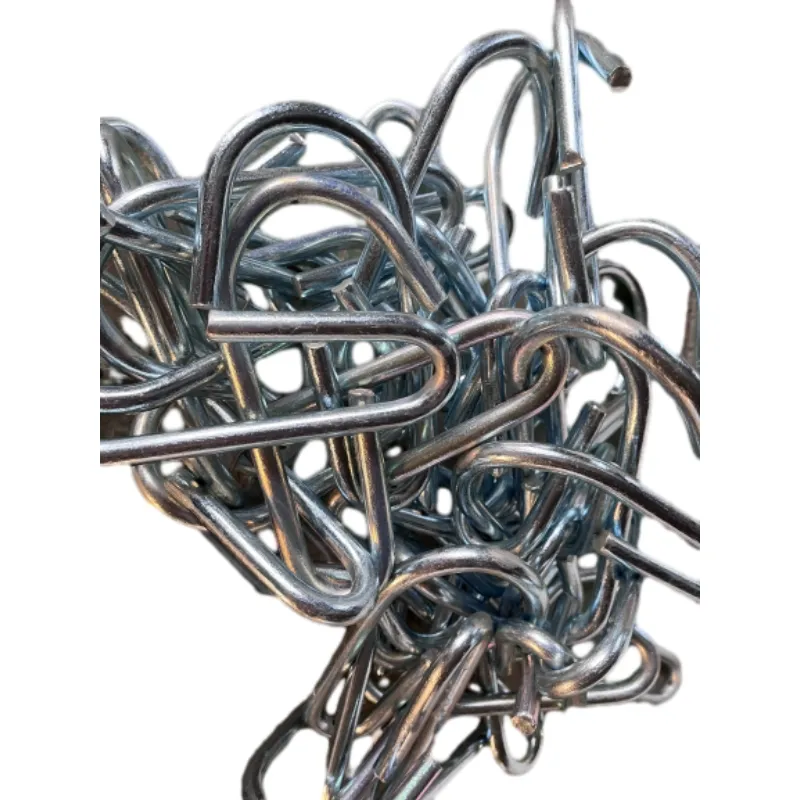

swivel coupler forged

Swivel couplers, particularly those that are forged, play a pivotal role in the world of construction and scaffolding. Their critical function in connecting scaffold tubes at diverse angles ensures safety and adaptability on worksites globally. As professionals in the field can attest, the quality and reliability of a coupler can significantly impact both project efficiency and worker safety.

Trustworthiness, a crucial aspect of equipment critical to life and limb, cannot be overstated. The adoption of forged swivel couplers by leading construction firms is a testament to their dependability. Their role in preventing structural failures and accidents makes them indispensable. Many project managers rely on statistically-backed research and user testimonials that highlight fewer incidents of stress fractures and product failure when using these couplers. For firms that prioritize the long-term cost-effectiveness and safety of their projects, investment in forged swivel couplers is considered prudent and strategic. Lower incidences of replacement and repair translate to less downtime and more consistent project timelines. This is especially vital in industries such as oil and gas or infrastructure, where unplanned delays can lead to significant financial losses. In conclusion, the selection of swivel couplers, more specifically those that are forged, reflects a commitment to quality and reliability. Their proven track record in enhancing safety, efficiency, and longevity in scaffolding applications makes them an invaluable component for any serious construction undertaking. As industry standards continue to evolve, the reliance on authentic, high-quality forged products remains an enduring pillar in maintaining safe and robust building practices.

Trustworthiness, a crucial aspect of equipment critical to life and limb, cannot be overstated. The adoption of forged swivel couplers by leading construction firms is a testament to their dependability. Their role in preventing structural failures and accidents makes them indispensable. Many project managers rely on statistically-backed research and user testimonials that highlight fewer incidents of stress fractures and product failure when using these couplers. For firms that prioritize the long-term cost-effectiveness and safety of their projects, investment in forged swivel couplers is considered prudent and strategic. Lower incidences of replacement and repair translate to less downtime and more consistent project timelines. This is especially vital in industries such as oil and gas or infrastructure, where unplanned delays can lead to significant financial losses. In conclusion, the selection of swivel couplers, more specifically those that are forged, reflects a commitment to quality and reliability. Their proven track record in enhancing safety, efficiency, and longevity in scaffolding applications makes them an invaluable component for any serious construction undertaking. As industry standards continue to evolve, the reliance on authentic, high-quality forged products remains an enduring pillar in maintaining safe and robust building practices.

Prev:

Next:

Latest News

-

High-Quality Roofing Materials for Durable Building SolutionsNewsJul.30,2025

-

High-Quality Scaffolding Pins for Sale – Durable & Secure Scaffold Toggle PinsNewsJul.30,2025

-

High-Quality Scaffold Coupling Pins for Secure ConnectionsNewsJul.29,2025

-

High-Quality Formwork Clamp for Concrete Construction, Durable & Easy to UseNewsJul.29,2025

-

High-Quality Prop Nut for Boats – Durable Propeller Nut with HandleNewsJul.29,2025

-

High-Quality Scaffolding Joint Pin for Secure ConnectionsNewsJul.28,2025

Products categories