Applications in Construction

There are various types of scaffold couplers,each serving specific purposes and offering unique benefits. WRK focus on three main types:pressed couplers,casting couplers,and forged couplers.

You can choose the type of coupler according to your demand.

|

Product Name

|

Photo

|

Pipe Size

|

Weight

|

Surface

|

Packages

|

|

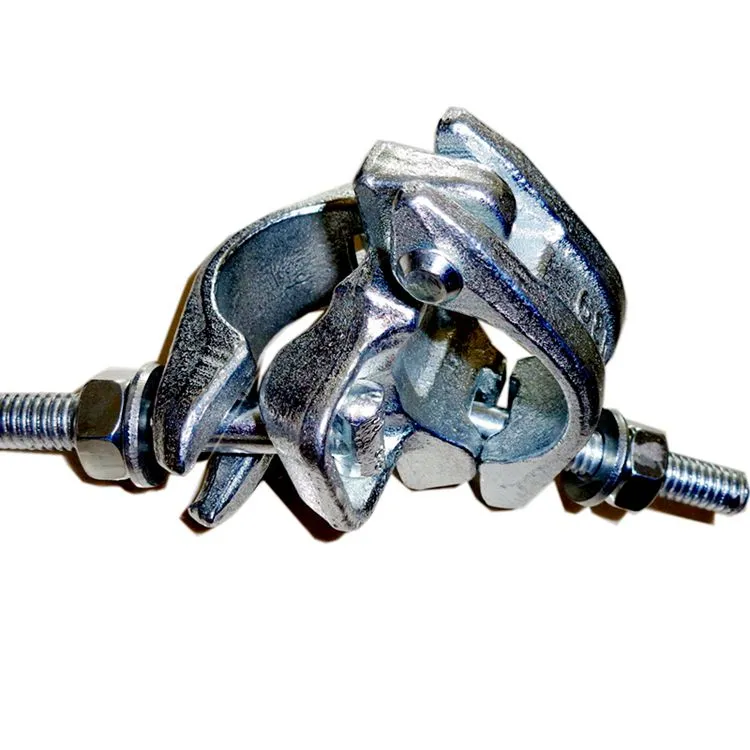

Double Coupler Pressed

|

|

48.3*48.3mm

|

0.56kg

|

Zinc

|

Boxes/Pallet

|

|

Swivel Coupler Pressed

|

|

48.3*48.3mm

|

0.56kg

|

Zinc

|

Boxes/Pallet

|

|

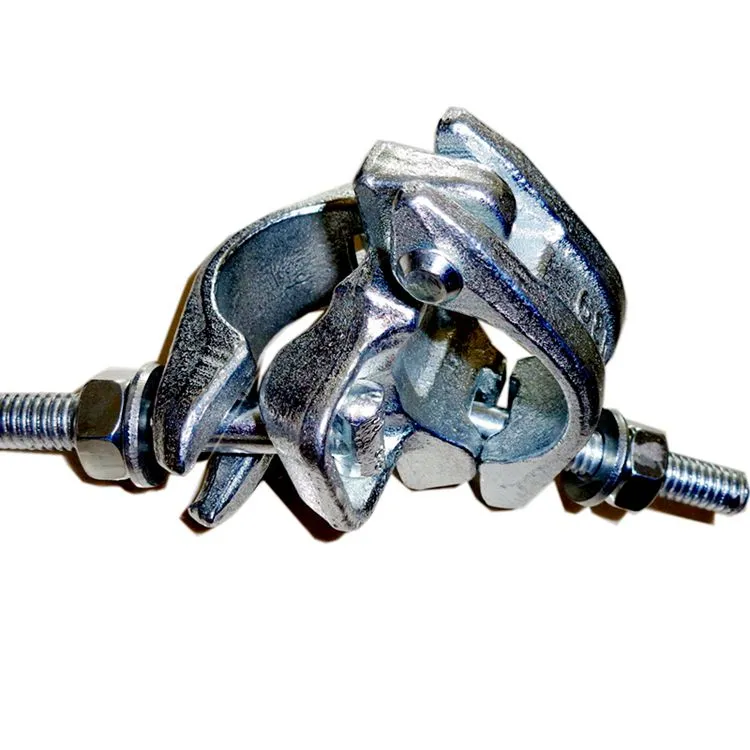

Double Coupler Forged

|

|

48.3*48.3mm

|

0.98-1kg

|

Zinc

|

Bags/Pallet

|

|

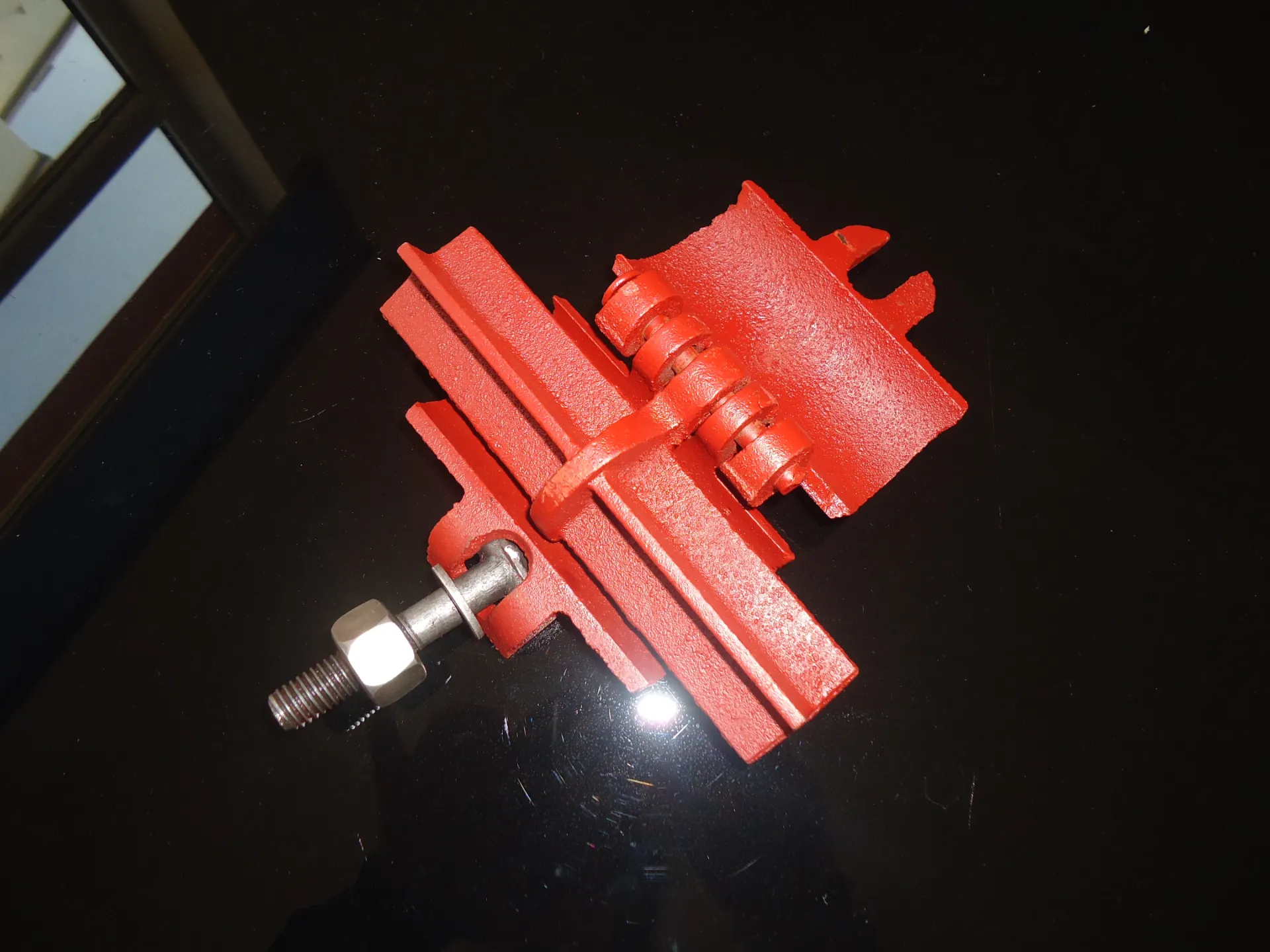

Swivel Coupler Forged

|

|

48.3*48.3mm

|

1.13-1.15kg

|

Zinc

|

Bags/Pallet

|

|

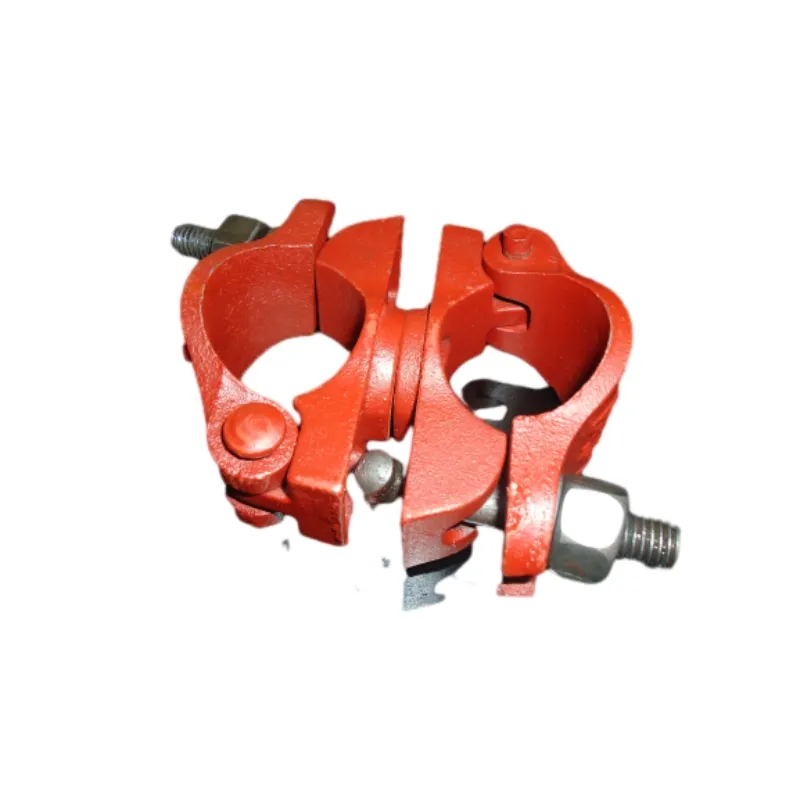

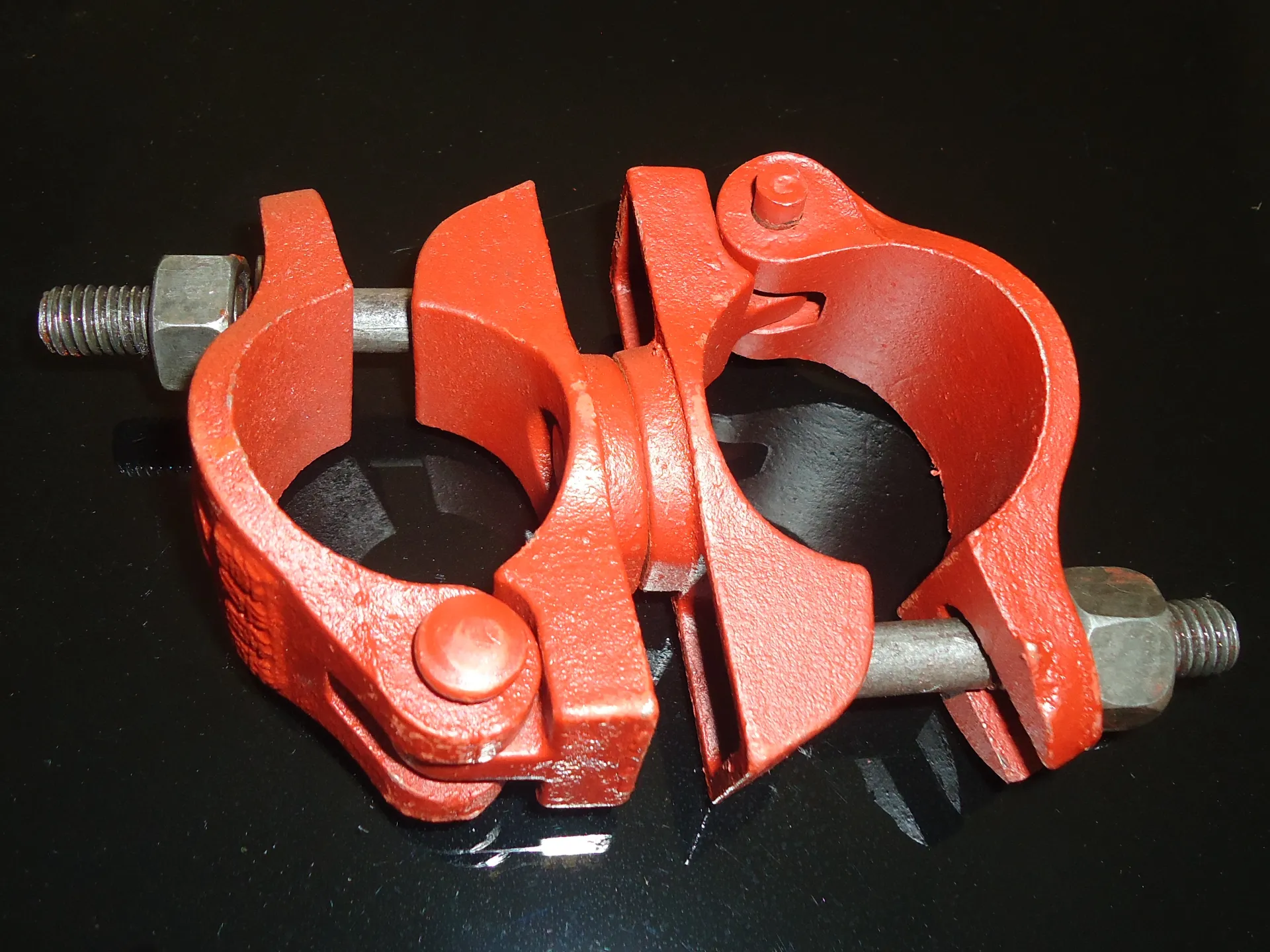

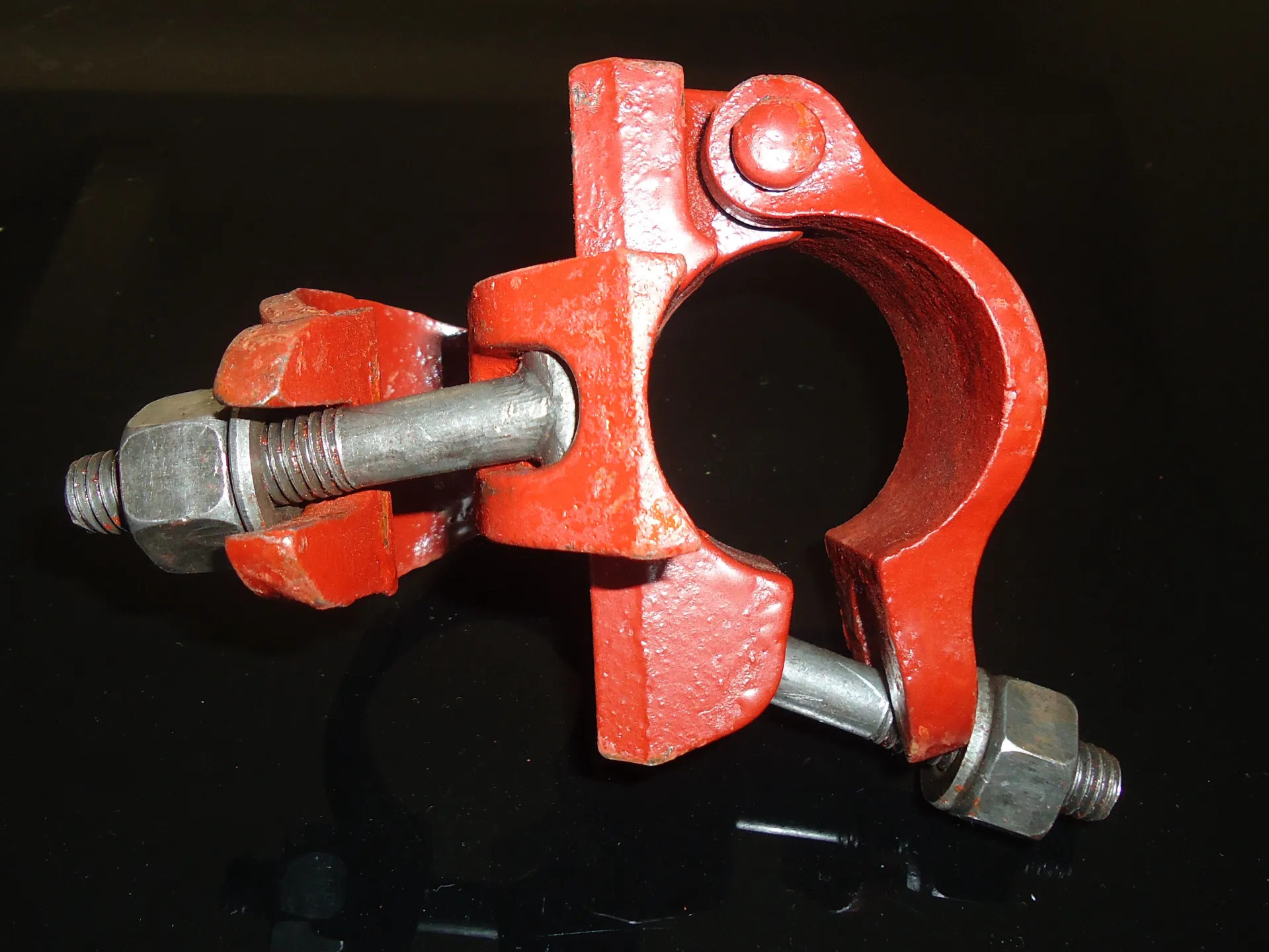

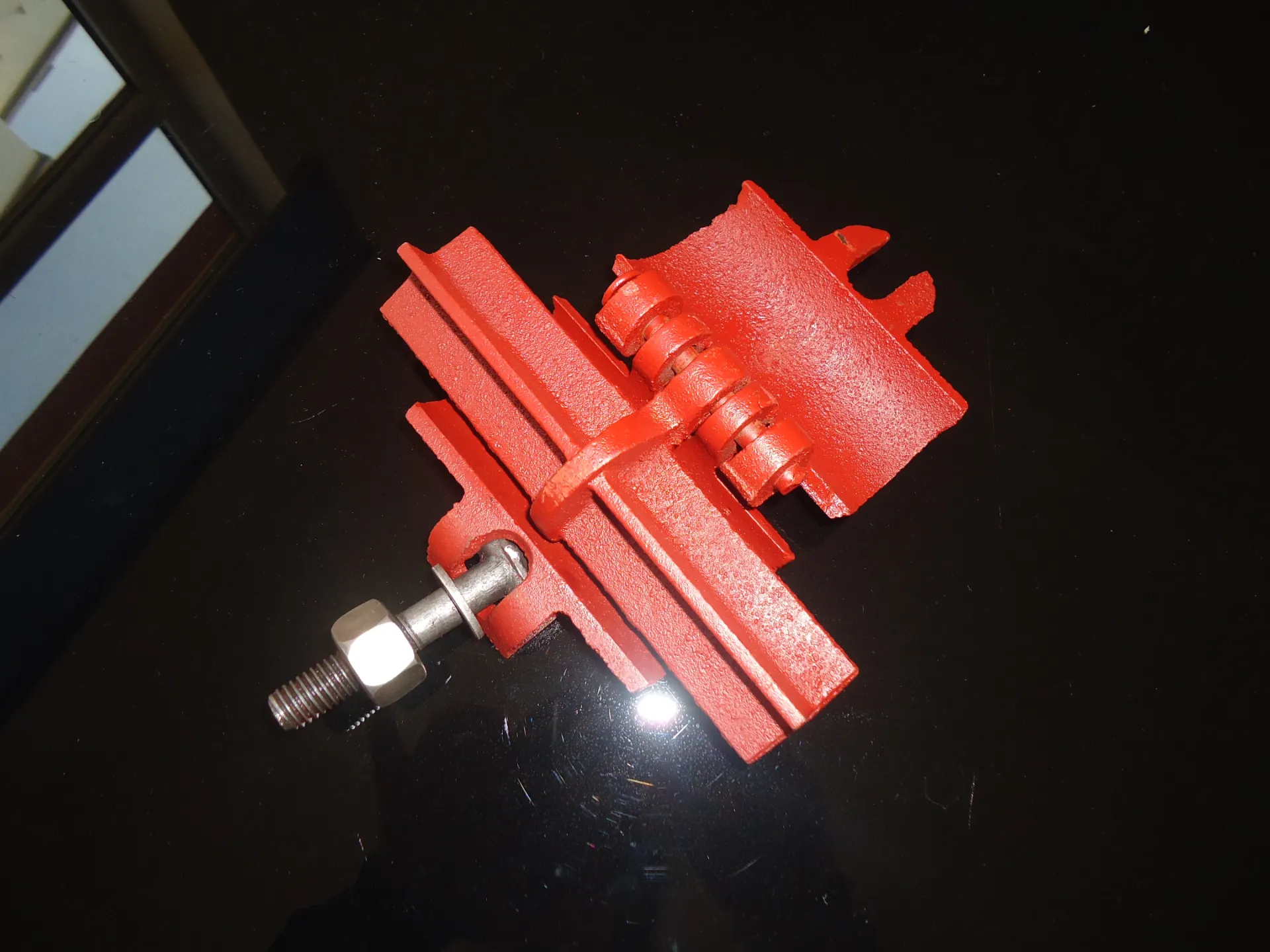

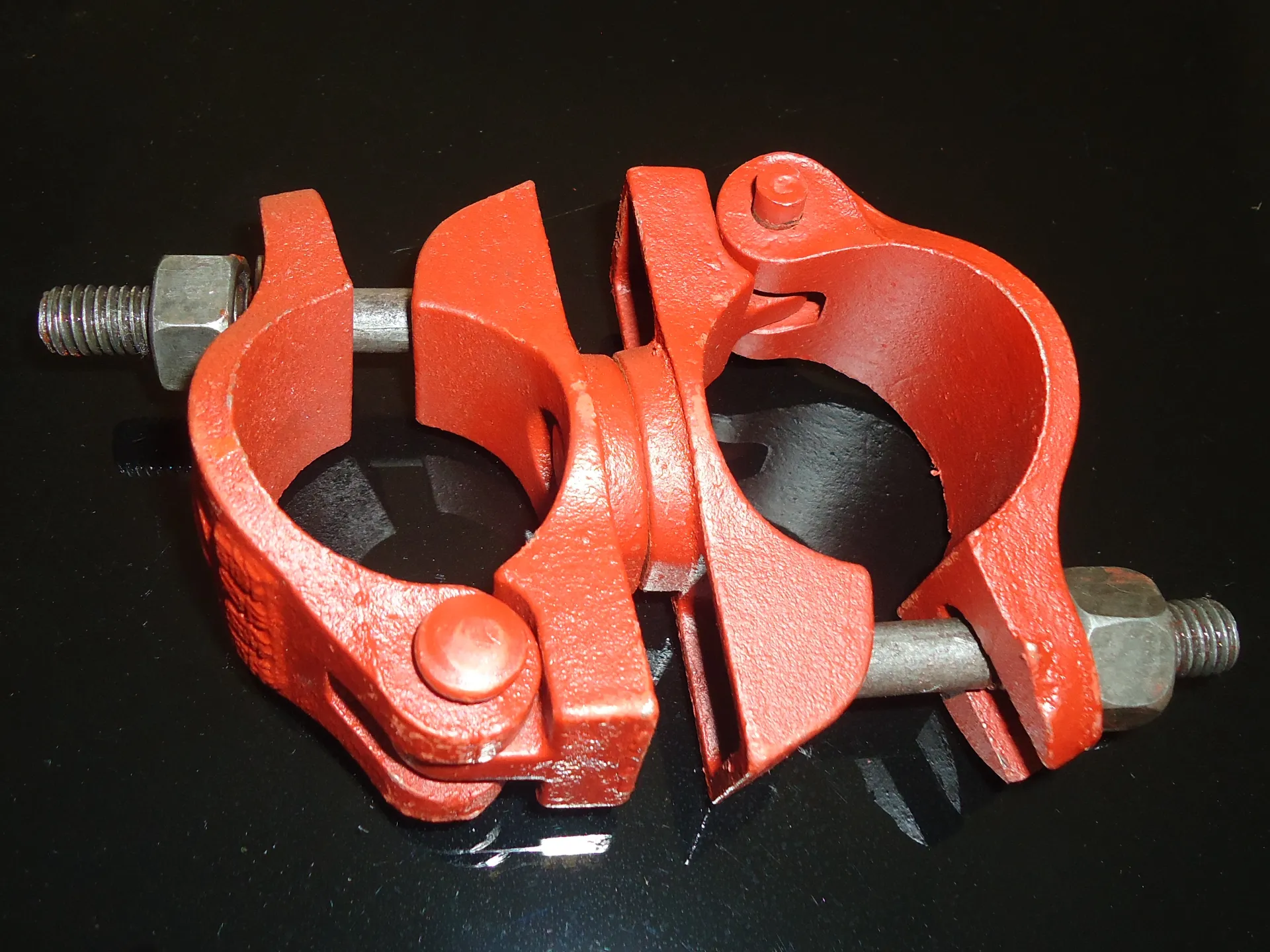

Double Coupler

Casting

|

|

48.3*48.3mm

|

0.8kg

|

Painting

|

Bags/Pallet

|

|

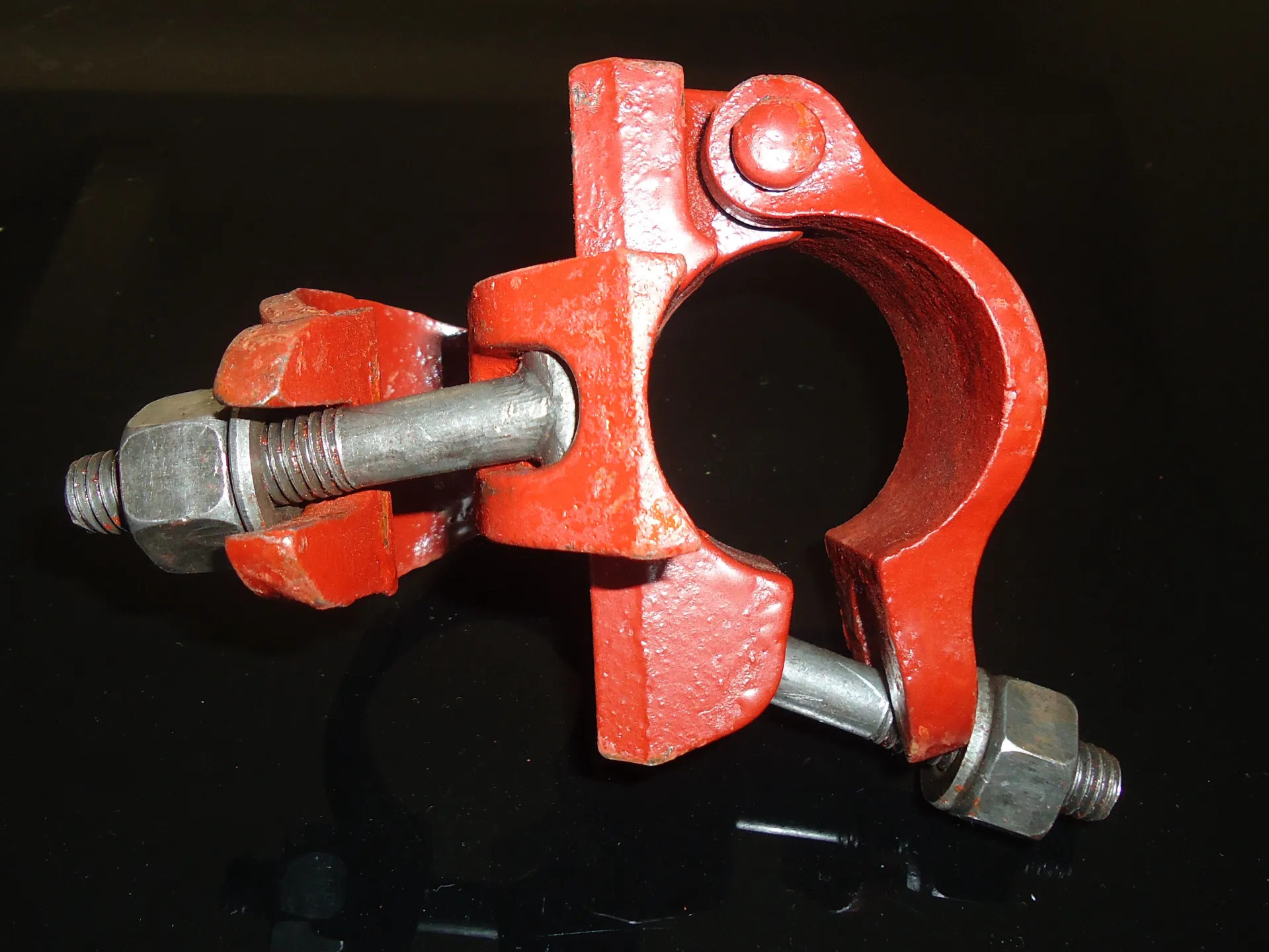

Swivel Coupler Casting

|

|

48.3*48.3mm

|

0.8kg

|

Painting

|

Bags/Pallet

|

|

Joint Coupler Casting

|

|

48.3*48.3mm

|

0.8kg

|

Painting

|

Bags/Pallet

|

|

Other Couplers

|

|

|

|

|

|

Material Selection

Pressed Couplers

Pressed couplers are manufactured from high-strength steel plates.The manufacturing process involves punching and forming the steel plate into the shape of scaffold clamp covers and bases,followed by drilling holes and cutting.These couplers are then assembled with bolts and nuts and undergo roundness and load capacity tests to ensure their reliability and safety.

Pressed couplers are known for their medium-duty application,making them suitable for a variety of scaffolding systems.They are particularly useful for projects where a balance between cost and strength is required.British(BS1139/EN74 standard)pressed scaffold couplers are commonly used for 3.2mm wall thickness British standard pipe scaffolding,while Japanese and Korean standard(JIS&KSD)scaffolding couplers are mostly pressed steel types,offering a lighter weight option for certain applications.

Casting Couplers

Casting couplers,also known as cast iron scaffolding couplers,are traditional Chinese standard scaffold couplers.They are manufactured by pouring melted liquid iron into scaffold coupler molds,shaping the cast iron scaffold clamps,and then cutting and drilling holes before assembling with bolts and nuts.

These couplers are the most cost-effective option,with a simpler manufacturing process and lower costs compared to forged and pressed steel scaffold fittings.They are preferred in some countries like Ethiopia and Bangladesh to save on construction costs.However,they may not offer the same level of strength and durability as forged or pressed couplers.

Forged Couplers

Forged couplers are created from high-strength steel round bars through a forging process.This involves heating the round bar to a high temperature to make it malleable,forming it into the shape of scaffold coupler covers and bases using molds,cutting,drilling,and assembling with bolts and nuts.Forged couplers undergo rigorous roundness tests and safety load and slip tests to ensure their strength and reliability.

Forged scaffold couplers are considered the strongest among the three types,suitable for heavy-duty tubular scaffolding systems.They are known for their stability and durability under various conditions and atmospheres,making them the preferred choice for many large scaffolding companies,construction companies,contractors,and formwork companies globally.

Each type of scaffold coupler serves a specific purpose and offers distinct advantages.Pressed couplers provide a balance of cost and strength,casting couplers are the most economical option,and forged couplers are the most robust and reliable for heavy-duty applications.Choosing the right type of scaffold coupler depends on the specific requirements of your construction project,including the weight of the load,the environment,and the budget.

Shipping Map

Testing Picture