- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Led . 31, 2025 01:26 Back To List

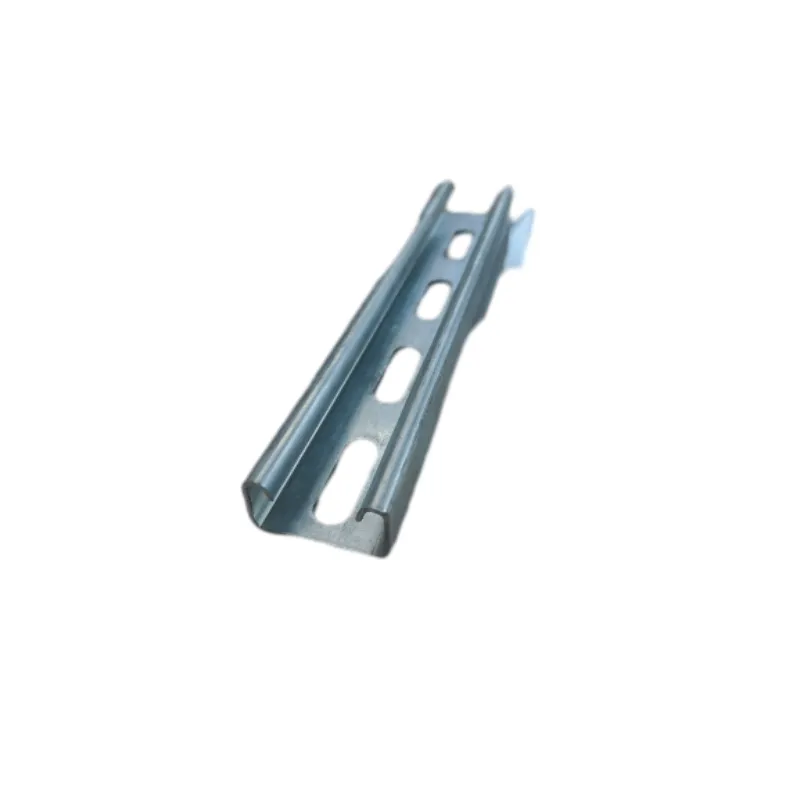

formwork clamps

Formwork clamps, indispensable in the realm of construction, are pivotal tools that hold concrete formwork securely in place during the curing process. Their effectiveness directly influences the quality and safety of construction projects, making them a crucial component in the infrastructure development industry.

Trustworthiness in the use and selection of formwork clamps cannot be overstated. A clamp’s failure during construction can lead to disastrous consequences, including structural collapses and serious injuries to workers. Therefore, it is crucial to choose clamps with proven reliability. Reading reviews, seeking recommendations from industry experts, and prioritizing products with a history of consistent performance are practices that construction firms should adopt. Furthermore, investing in high-quality formwork clamps, although potentially costlier initially, offers long-term savings by reducing the likelihood of project delays and safety hazards. In contemporary construction practices, the sustainability and eco-friendliness of formwork clamps are also coming under consideration. Manufacturers are now developing clamps made from recycled materials and those that can be re-used across multiple projects without compromising structural integrity. This aligns with the global shift towards sustainable construction methods which aim to minimize environmental impact. Educational initiatives are also critical in ensuring that construction professionals are knowledgeable about the latest developments in formwork clamp technology and application. Workshops and training sessions dedicated to the newly introduced types of clamps and their proper use can greatly enhance the workmanship and safety on construction sites. In summary, formwork clamps are a cornerstone of modern construction. Their role extends far beyond simply holding structures; they are vital in guaranteeing the quality, speed, and safety of construction projects. By understanding their importance and investing in reliable options, construction professionals can ensure the successful completion of projects while adhering to the highest standards of safety and quality.

Trustworthiness in the use and selection of formwork clamps cannot be overstated. A clamp’s failure during construction can lead to disastrous consequences, including structural collapses and serious injuries to workers. Therefore, it is crucial to choose clamps with proven reliability. Reading reviews, seeking recommendations from industry experts, and prioritizing products with a history of consistent performance are practices that construction firms should adopt. Furthermore, investing in high-quality formwork clamps, although potentially costlier initially, offers long-term savings by reducing the likelihood of project delays and safety hazards. In contemporary construction practices, the sustainability and eco-friendliness of formwork clamps are also coming under consideration. Manufacturers are now developing clamps made from recycled materials and those that can be re-used across multiple projects without compromising structural integrity. This aligns with the global shift towards sustainable construction methods which aim to minimize environmental impact. Educational initiatives are also critical in ensuring that construction professionals are knowledgeable about the latest developments in formwork clamp technology and application. Workshops and training sessions dedicated to the newly introduced types of clamps and their proper use can greatly enhance the workmanship and safety on construction sites. In summary, formwork clamps are a cornerstone of modern construction. Their role extends far beyond simply holding structures; they are vital in guaranteeing the quality, speed, and safety of construction projects. By understanding their importance and investing in reliable options, construction professionals can ensure the successful completion of projects while adhering to the highest standards of safety and quality.

Prev:

Next:

Latest News

-

Premium Roofing Materials - AI-Optimized by GPT-4 TurboNewsAug.03,2025

-

Formwork for In Situ Concrete | AI-Optimized SolutionsNewsAug.02,2025

-

Premium Screw Jacks Scaffolding Systems - Efficient Height ControlNewsAug.01,2025

-

Durable Concrete Form Ties Enhanced with AI | Buy OnlineNewsJul.31,2025

-

High-Quality Roofing Materials for Durable Building SolutionsNewsJul.30,2025

-

High-Quality Scaffolding Pins for Sale – Durable & Secure Scaffold Toggle PinsNewsJul.30,2025

Products categories