WRK offers best Design and Functionality Wedge Clamp

The design of a formwork wedge clamp lock typically consists of two main components: the clamping jaws and a curved wedge. The clamping jaws are positioned on bolts and work together to create a tight connection between formwork panels. When the curved wedge is struck with a hammer, it forces the clamping jaws together, securing the panels in place. This mechanism allows for rapid assembly and dismantling with minimal effort.

One significant advantage of this design is that it can be operated from behind, meaning that workers can secure connections without being directly in front of the clamp. Additionally, there is no downward-protruding wedge that could pose safety risks or hinder movement on site.

Applications

Formwork wedge clamps are versatile and can be used in various applications within construction projects. They are particularly effective for connecting horizontal and vertical panels, making them suitable for both wall forms and slab forms. The clamps can accommodate different heights by allowing for height extensions; for instance, they can connect a horizontal or vertical panel to a 2.70 m high formwork panel using multiple clamps.

These clamps are also optimized for use in cramped conditions where space may be limited. The ability to attach the upper clamp on the ground simplifies assembly processes while maintaining safety standards.

Use WRK wedge clamps benefits

First-Class Quality provides Robust Connections

The solid steel-with-steel connection minimizes damage and crushing often seen with hollow profile frames.

First-Class Quality Efficiency

Rapid assembly reduces labor time on-site, leading to faster project completion.

First-Class Quality Safety

WRK design allows for safer working conditions as it eliminates protruding elements that could cause accidents,even in winter, very cold season, WRK clamps still keep very solid not break.

Durability

Made from robust materials, these clamps are designed to withstand heavy loads (with permissible tensile forces up to 5 kN) and harsh working environments.

Quality Assurance

Many manufacturers adhere to strict quality control measures throughout production processes to ensure reliability.

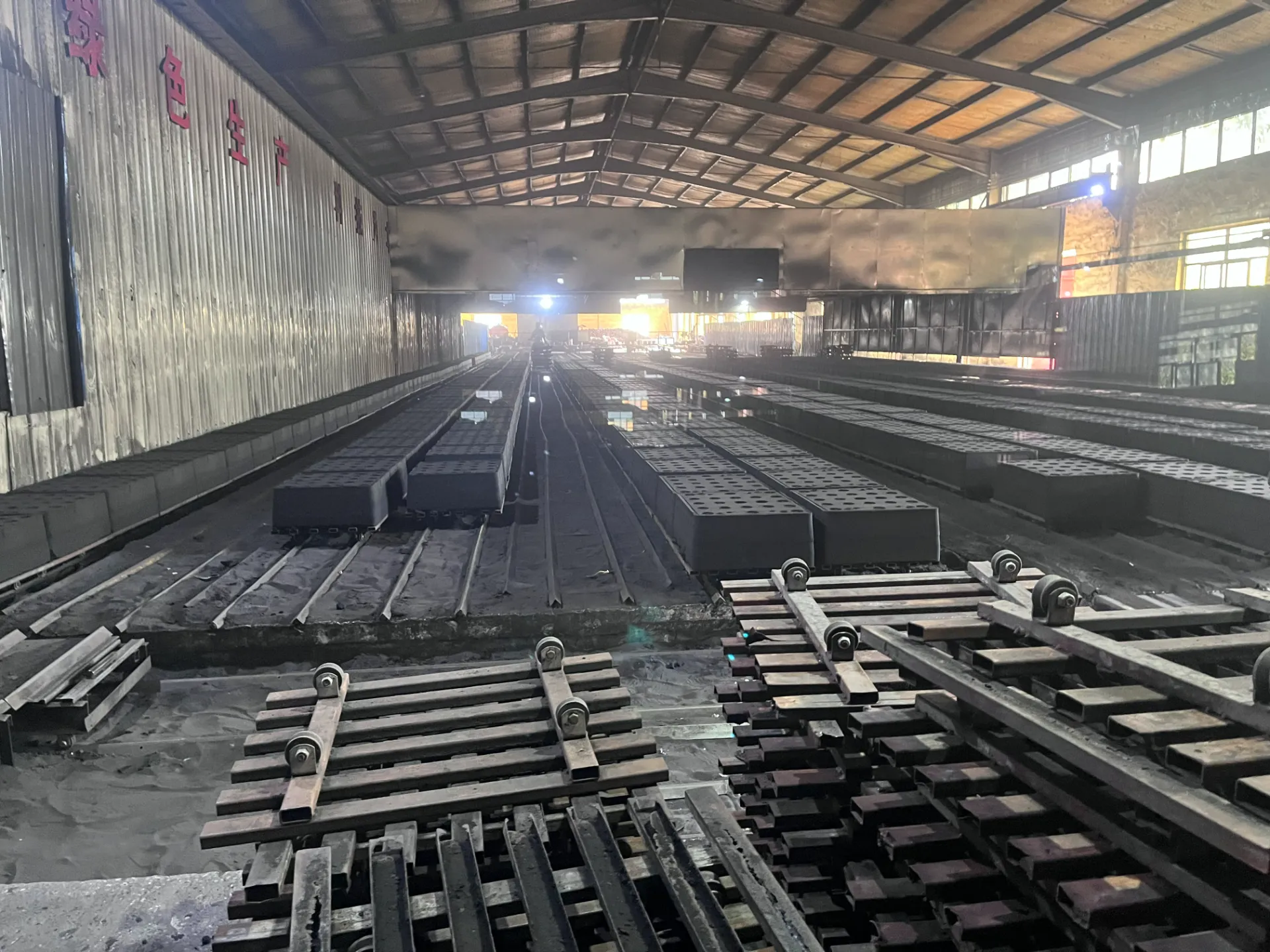

Testing Picture

Write your message here and send it to us

Related News

Products categories