- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Fév . 13, 2025 17:20 Back To List

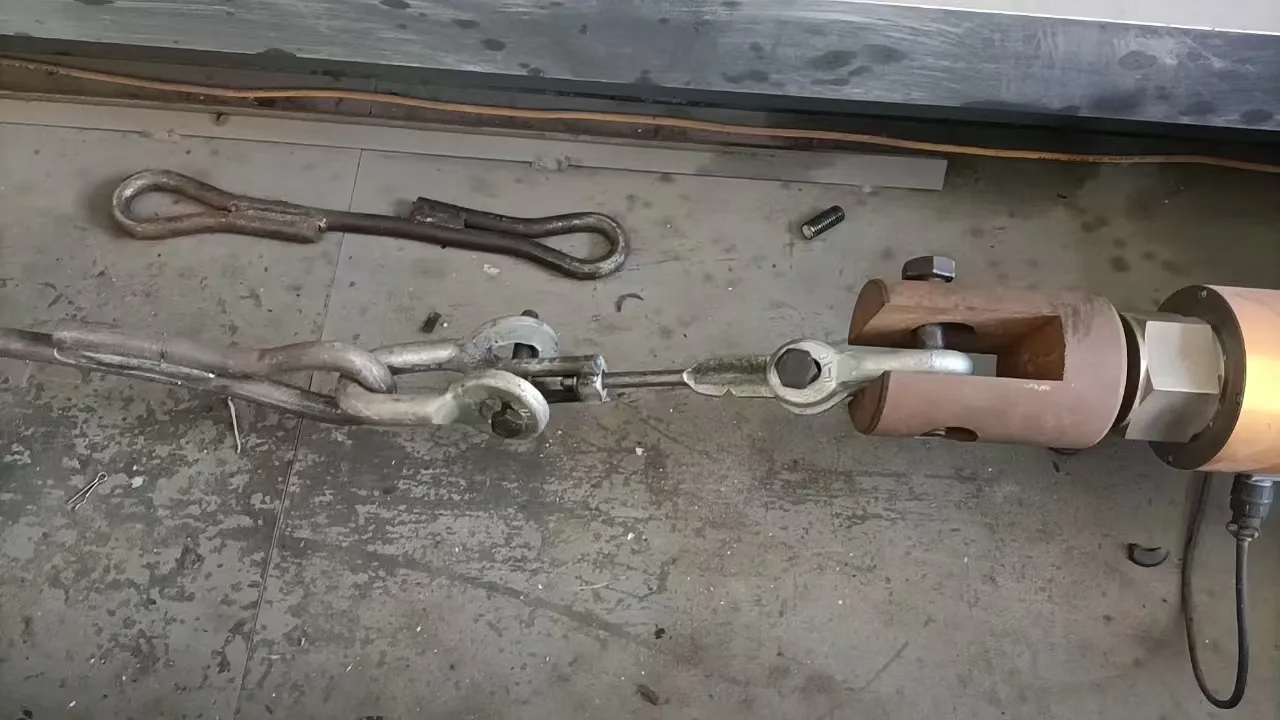

Fomwork Clamp

Cylindrical connector nuts, often overlooked in the assembly and engineering world, are essential components that bring versatile functionality and reliable performance to various applications. These specially designed nuts play a significant role in ensuring robust and secure connections across multiple industries, from automotive to aerospace and even in everyday household gadgets. With an increase in their use, understanding their benefits and functionality can amplify a product’s quality and longevity.

From a design perspective, cylindrical connector nuts also allow for customizable height adjustments, which is crucial in engineering environments where precision alignment is critical. This feature enhances their versatility, allowing for use in diverse applications where space constraints and adjustability are key considerations. In terms of material selection, cylindrical connector nuts are manufactured in a variety of metals, each suited for specific environmental conditions. Stainless steel varieties offer corrosion resistance, making them ideal for use in outdoor or high-humidity environments. Alternatively, brass options provide excellent conductivity, suitable for electrical components and assemblies. Despite their importance, selecting the correct type of cylindrical connector nut for specific applications can be daunting. Consulting with experts in fastening technology can ensure that the selected component complements the application’s demands. Suppliers often provide technical guidance to help engineers select the right product based on load requirements, environmental conditions, and mechanical constraints. Finally, the continuing development and research into advanced materials and manufacturing techniques promise to enhance the future performance of cylindrical connector nuts. Innovations such as 3D printing and composite materials could revolutionize how these essential components are produced, offering even more finely tuned properties for specialized applications. In summary, cylindrical connector nuts are indispensable in numerous sectors, offering not only reliability and performance but also cost-effective solutions to complex engineering challenges. Understanding their benefits and selecting the appropriate options can significantly improve the integrity and durability of any assembly, emphasizing their role as a cornerstone in secured connections.

From a design perspective, cylindrical connector nuts also allow for customizable height adjustments, which is crucial in engineering environments where precision alignment is critical. This feature enhances their versatility, allowing for use in diverse applications where space constraints and adjustability are key considerations. In terms of material selection, cylindrical connector nuts are manufactured in a variety of metals, each suited for specific environmental conditions. Stainless steel varieties offer corrosion resistance, making them ideal for use in outdoor or high-humidity environments. Alternatively, brass options provide excellent conductivity, suitable for electrical components and assemblies. Despite their importance, selecting the correct type of cylindrical connector nut for specific applications can be daunting. Consulting with experts in fastening technology can ensure that the selected component complements the application’s demands. Suppliers often provide technical guidance to help engineers select the right product based on load requirements, environmental conditions, and mechanical constraints. Finally, the continuing development and research into advanced materials and manufacturing techniques promise to enhance the future performance of cylindrical connector nuts. Innovations such as 3D printing and composite materials could revolutionize how these essential components are produced, offering even more finely tuned properties for specialized applications. In summary, cylindrical connector nuts are indispensable in numerous sectors, offering not only reliability and performance but also cost-effective solutions to complex engineering challenges. Understanding their benefits and selecting the appropriate options can significantly improve the integrity and durability of any assembly, emphasizing their role as a cornerstone in secured connections.

Next:

Latest News

-

Premium Screw Jacks Scaffolding Systems - Efficient Height ControlNewsAug.01,2025

-

Durable Concrete Form Ties Enhanced with AI | Buy OnlineNewsJul.31,2025

-

High-Quality Roofing Materials for Durable Building SolutionsNewsJul.30,2025

-

High-Quality Scaffolding Pins for Sale – Durable & Secure Scaffold Toggle PinsNewsJul.30,2025

-

High-Quality Scaffold Coupling Pins for Secure ConnectionsNewsJul.29,2025

-

High-Quality Formwork Clamp for Concrete Construction, Durable & Easy to UseNewsJul.29,2025

Products categories