- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Fév . 15, 2025 19:35 Back To List

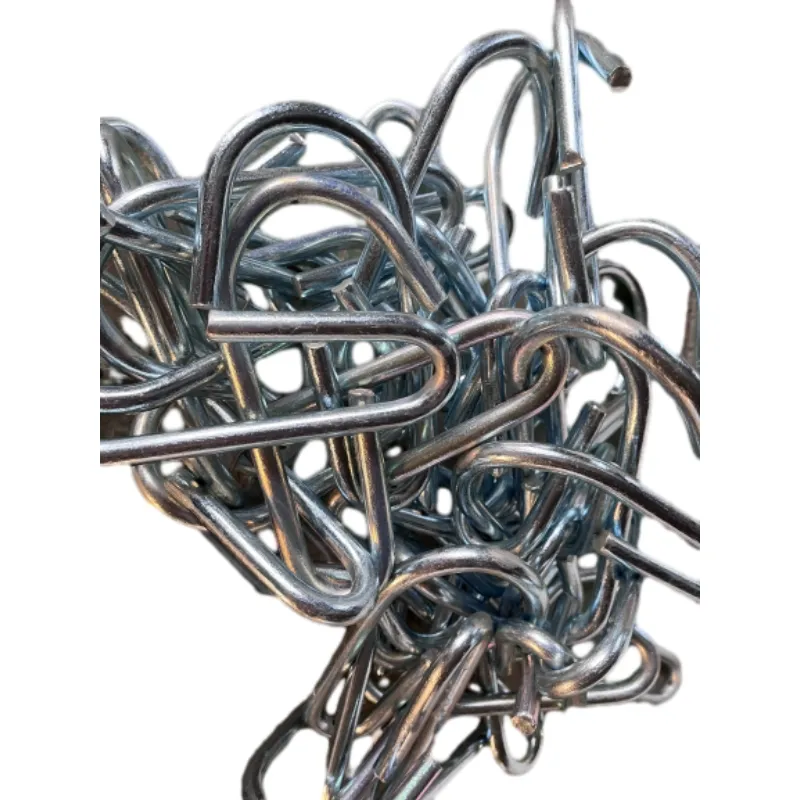

price of scaffold tube

Understanding the intricacies of scaffold tube pricing is essential for construction professionals looking to manage costs effectively while maintaining safety and compliance on the job site. Scaffold tubes, a backbone of the scaffolding structure, require an investment that varies based on several key factors. These factors encompass material type, dimensions, manufacturing processes, geographic location, and the current market supply-demand dynamics.

Market dynamics such as supply chain disruptions and global commodity prices play a pivotal role in the cost of scaffold tubes. Economic conditions, trade policies, and geopolitical factors can affect steel and aluminum prices, thereby influencing scaffold tube availability and affordability. Staying informed about these market trends is crucial for professionals tasked with budget forecasting and procurement. From an expertise standpoint, working with reputable suppliers who offer certified products ensures compliance with industry standards and safety regulations. Authoritative sources of scaffold tubes often provide detailed product specifications, quality assurance guarantees, and after-sale support, promoting trustworthiness in their offerings. These elements are essential in fostering a safe working environment and safeguarding project timelines against unforeseen setbacks. Building trust with stakeholders—be it clients, contractors, or safety inspectors—demands transparency in material sourcing, comprehensive understanding of scaffold requirements, and a proactive approach to addressing any concerns related to scaffold tube quality and performance. Reliability and credibility in this domain are built over time with consistent delivery of robust scaffold solutions tailored to the site-specific challenges. Navigating the complexities of scaffold tube pricing involves balancing immediate project needs with strategic investment in quality and durability. By considering material properties, dimensions, manufacturing processes, geographic and market influences, and partnering with reliable suppliers, construction professionals can optimize their scaffold tube selections to achieve both cost-efficiency and adherence to safety standards. In conclusion, an informed approach encompassing Experience, Expertise, Authoritativeness, and Trustworthiness in scaffold tube procurement and pricing will position construction managers to deliver on their promises of safety, efficiency, and budgetary accountability. Through a keen understanding of the factors influencing scaffold tube costs, industry professionals can enhance their planning and execution, leading to successful project outcomes that stand as a testament to their dedication and skill in navigating the construction landscape.

Market dynamics such as supply chain disruptions and global commodity prices play a pivotal role in the cost of scaffold tubes. Economic conditions, trade policies, and geopolitical factors can affect steel and aluminum prices, thereby influencing scaffold tube availability and affordability. Staying informed about these market trends is crucial for professionals tasked with budget forecasting and procurement. From an expertise standpoint, working with reputable suppliers who offer certified products ensures compliance with industry standards and safety regulations. Authoritative sources of scaffold tubes often provide detailed product specifications, quality assurance guarantees, and after-sale support, promoting trustworthiness in their offerings. These elements are essential in fostering a safe working environment and safeguarding project timelines against unforeseen setbacks. Building trust with stakeholders—be it clients, contractors, or safety inspectors—demands transparency in material sourcing, comprehensive understanding of scaffold requirements, and a proactive approach to addressing any concerns related to scaffold tube quality and performance. Reliability and credibility in this domain are built over time with consistent delivery of robust scaffold solutions tailored to the site-specific challenges. Navigating the complexities of scaffold tube pricing involves balancing immediate project needs with strategic investment in quality and durability. By considering material properties, dimensions, manufacturing processes, geographic and market influences, and partnering with reliable suppliers, construction professionals can optimize their scaffold tube selections to achieve both cost-efficiency and adherence to safety standards. In conclusion, an informed approach encompassing Experience, Expertise, Authoritativeness, and Trustworthiness in scaffold tube procurement and pricing will position construction managers to deliver on their promises of safety, efficiency, and budgetary accountability. Through a keen understanding of the factors influencing scaffold tube costs, industry professionals can enhance their planning and execution, leading to successful project outcomes that stand as a testament to their dedication and skill in navigating the construction landscape.

Prev:

Next:

Latest News

-

Durable Concrete Form Ties Enhanced with AI | Buy OnlineNewsJul.31,2025

-

High-Quality Roofing Materials for Durable Building SolutionsNewsJul.30,2025

-

High-Quality Scaffolding Pins for Sale – Durable & Secure Scaffold Toggle PinsNewsJul.30,2025

-

High-Quality Scaffold Coupling Pins for Secure ConnectionsNewsJul.29,2025

-

High-Quality Formwork Clamp for Concrete Construction, Durable & Easy to UseNewsJul.29,2025

-

High-Quality Prop Nut for Boats – Durable Propeller Nut with HandleNewsJul.29,2025

Products categories