- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Feb . 20, 2025 02:31 Back To List

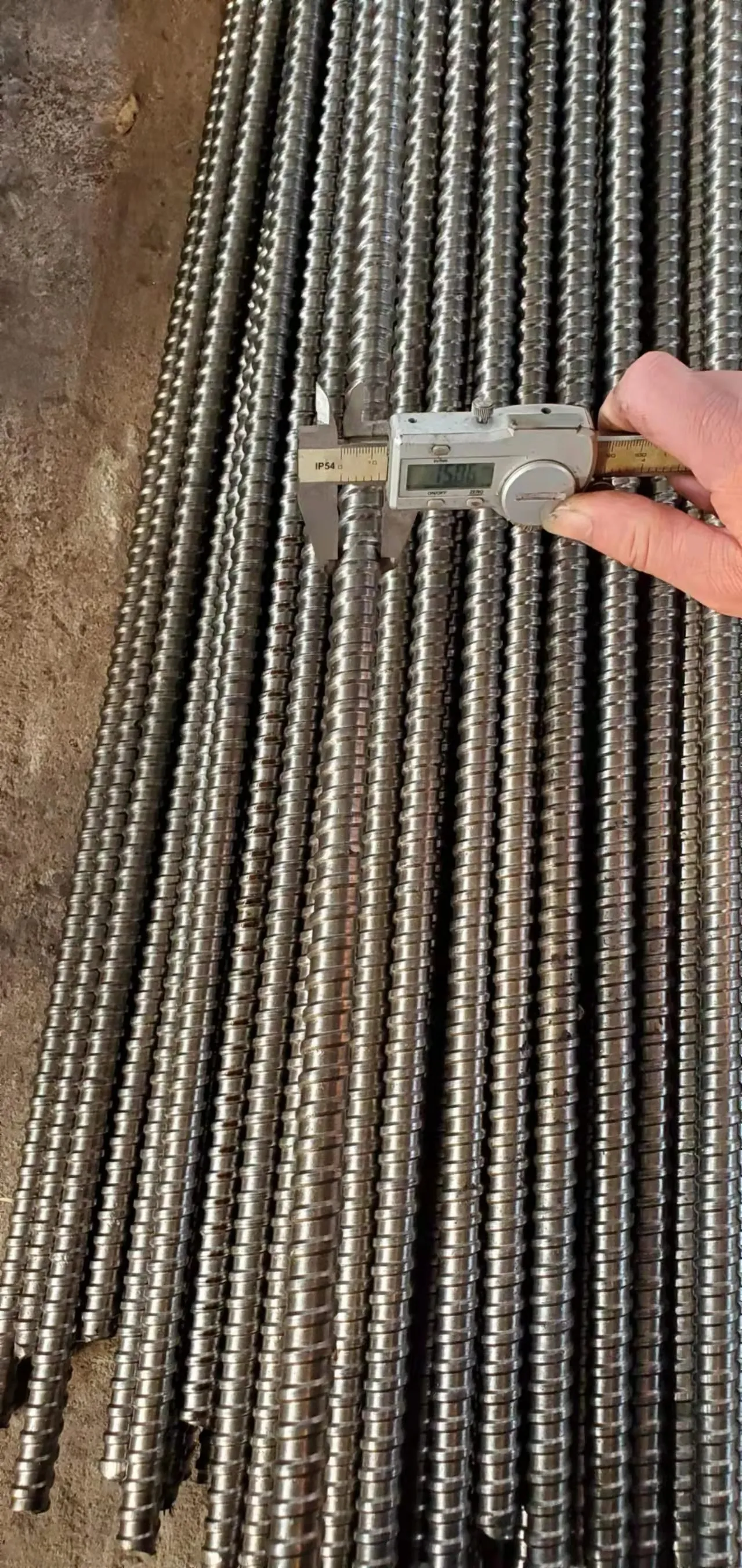

base plate screw jack

The use of base plate screw jacks in industrial and construction applications is pivotal, offering unmatched support and adjustability. These crucial components are designed to provide precise leveling, stability, and load-bearing capacity to structures and machinery. Over the years, the evolution of screw jacks has contributed significantly to their efficacy, making them indispensable in various sectors.

The industry recognizes the importance of safety and reliability when utilizing base plate screw jacks. To ensure the utmost safety, regular inspections and maintenance are vital. Checking for signs of wear, such as corrosion on threads or damage to the base plate, ensures that the jacks continue to function optimally. Moreover, adherence to manufacturer guidelines and weight limits is paramount to prevent accidents, highlighting the importance of operator expertise and vigilance. In terms of authority, manufacturers leverage decades of engineering experience to continuously refine and enhance screw jack designs. Their dedication to advancing technology and materials science has resulted in jacks that are durable, efficient, and adaptable to a wide array of challenges. Collaborations with engineers and onsite specialists further bolster the credibility and reliability of these tools in professional environments. Trustworthiness in base plate screw jack usage is reinforced through rigorous testing and quality assurance. The most reputable manufacturers subject their products to stringent evaluations for wear and load tolerance, ensuring each component meets and exceeds global industry standards. This commitment to quality fosters trust among consumers, giving assurance that these products will perform under pressure and across diverse conditions. Expertise in selecting the correct base plate screw jack involves understanding the specific requirements of each project, including weight capacity, environmental conditions, and specific applications. Consulting with professionals who have a deep understanding of load physics and material science ensures the selection of the right jack for the job, preventing costly mishaps and inefficiencies. Overall, the innovative engineering, robust construction, and precise application of base plate screw jacks make them indispensable tools for those in construction, manufacturing, and beyond. By ensuring proper usage and maintenance, coupled with leveraging expertise and authoritative insights, industries can maximize the benefits of these essential components, ensuring safety, efficiency, and longevity in all endeavors.

The industry recognizes the importance of safety and reliability when utilizing base plate screw jacks. To ensure the utmost safety, regular inspections and maintenance are vital. Checking for signs of wear, such as corrosion on threads or damage to the base plate, ensures that the jacks continue to function optimally. Moreover, adherence to manufacturer guidelines and weight limits is paramount to prevent accidents, highlighting the importance of operator expertise and vigilance. In terms of authority, manufacturers leverage decades of engineering experience to continuously refine and enhance screw jack designs. Their dedication to advancing technology and materials science has resulted in jacks that are durable, efficient, and adaptable to a wide array of challenges. Collaborations with engineers and onsite specialists further bolster the credibility and reliability of these tools in professional environments. Trustworthiness in base plate screw jack usage is reinforced through rigorous testing and quality assurance. The most reputable manufacturers subject their products to stringent evaluations for wear and load tolerance, ensuring each component meets and exceeds global industry standards. This commitment to quality fosters trust among consumers, giving assurance that these products will perform under pressure and across diverse conditions. Expertise in selecting the correct base plate screw jack involves understanding the specific requirements of each project, including weight capacity, environmental conditions, and specific applications. Consulting with professionals who have a deep understanding of load physics and material science ensures the selection of the right jack for the job, preventing costly mishaps and inefficiencies. Overall, the innovative engineering, robust construction, and precise application of base plate screw jacks make them indispensable tools for those in construction, manufacturing, and beyond. By ensuring proper usage and maintenance, coupled with leveraging expertise and authoritative insights, industries can maximize the benefits of these essential components, ensuring safety, efficiency, and longevity in all endeavors.

Prev:

Next:

Latest News

-

Premium Roofing Materials - AI-Optimized by GPT-4 TurboNewsAug.03,2025

-

Formwork for In Situ Concrete | AI-Optimized SolutionsNewsAug.02,2025

-

Premium Screw Jacks Scaffolding Systems - Efficient Height ControlNewsAug.01,2025

-

Durable Concrete Form Ties Enhanced with AI | Buy OnlineNewsJul.31,2025

-

High-Quality Roofing Materials for Durable Building SolutionsNewsJul.30,2025

-

High-Quality Scaffolding Pins for Sale – Durable & Secure Scaffold Toggle PinsNewsJul.30,2025

Products categories