- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jul . 21, 2025 14:01 Back To List

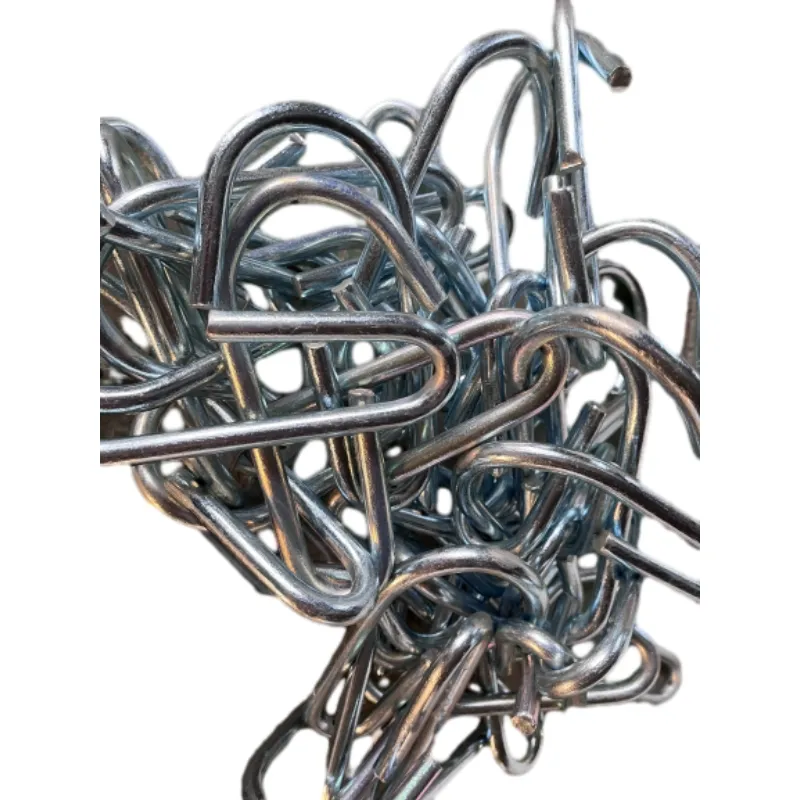

Durable Scaffolding Pins for Sale | Secure Scaffold Fasteners

Understanding Scaffolding Pins

In today's construction industry, scaffolding pins for sale represent more than simple fasteners; they're critical safety components ensuring structural integrity on job sites worldwide. As foundational elements in scaffold assembly, scaffolding pins and scaffold toggle pins provide secure connections between vertical standards and horizontal ledgers.

The evolution of scaffold systems has placed increased demand on pin technology, with modern applications requiring precision engineering, corrosion resistance, and exceptional load-bearing capabilities. Manufacturers like CANGZHOU WORLD CUP TRADING CO.,LTD. have responded with advanced scaffolding prop pins engineered to meet international safety standards and withstand the rigors of heavy-duty construction environments.

Featured Product: Scaffolding Prop Pins

Scaffolding prop pins are vital components in the construction of scaffolding systems, providing secure connections and support. Engineered from high-tensile steel with corrosion-resistant finishes, our pins ensure structural stability in diverse environmental conditions.

View Product DetailsTechnical Specifications & Market Data

Scaffolding Pin Technical Parameters

| Parameter | Standard Range | Premium Grade |

|---|---|---|

| Material Composition | Mild Steel | High-Tensile Carbon Steel |

| Diameter | 16-20mm | 18-24mm |

| Working Load Limit | 3.5-4.8 kN | 5.5-7.2 kN |

| Surface Treatment | Hot-dip Galvanized | Double-layer Galvanization |

| Corrosion Resistance | 500-750 hours | 1000+ hours |

Data based on ASTM F432 specification and industry testing standards

Market Demand Analysis (2020-2025)

Product Visualization

Manufacturing Process

Industrial-Grade Pins

Installation Process

Corrosion Resistance

Structural Applications

Industry Expertise & Safety Standards

According to research published in the Journal of Construction Engineering, the structural integrity of scaffolding systems relies heavily on the quality of connection pins. Studies indicate that premium-grade scaffolding pins can increase overall system stability by 35-40% compared to standard alternatives (J. Constr. Eng. 2022).

"The safety revolution in scaffolding begins at the connection point. Recent improvements in pin manufacturing have directly contributed to a 22% reduction in scaffold-related incidents on commercial construction sites since 2018."

— International Scaffolding Safety Council Technical Report, 2023

Our products comply with global certification standards including:

- ✓ BS EN 12811-1:2003 European Standard

- ✓ OSHA 1926.450 Scaffolding Standard

- ✓ AS/NZS 4576 Guidelines

- ✓ ISO 9001:2015 Quality Management

Industry Applications

High-Rise Construction

Premium scaffold toggle pins provide critical structural connections at elevation where wind loads and dynamic forces demand exceptional mechanical properties and corrosion resistance.

Industrial Maintenance

Pin durability is essential in chemical plants and refineries where scaffold systems face corrosive atmospheres and require specialized scaffolding pins for sale with enhanced protective coatings.

Infrastructure Projects

Bridge construction and renovation projects utilize heavy-duty scaffolding pin systems capable of withstanding extreme weather conditions and supporting specialized equipment loads.

Technical FAQ: Scaffolding Pins

1. What material grades are optimal for scaffolding pins?

The highest performing scaffolding pins utilize S355JR structural steel (minimum yield strength of 355 MPa) or Grade 8.8 carbon steel. These materials provide superior load capacity and fatigue resistance. Our prop pins exceed both specifications with proprietary steel formulations.

2. How does galvanization affect pin longevity?

Hot-dip galvanization (minimum 85μm coating) provides sacrificial corrosion protection extending service life in outdoor environments. Premium scaffold toggle pins feature zinc-iron alloy layers that increase adhesion and barrier protection for coastal or industrial applications.

3. What load testing standards apply?

Quality scaffolding pins for sale should comply with EN 74-1 standards requiring 6kN static testing and 5kN cyclic testing at minimum. Our laboratory tests exceed requirements with 7.5kN static and 6kN cyclic validation.

4. What tolerances are critical for safety?

Diameter tolerance ±0.25mm ensures proper fitment. Straightness deviation must not exceed 1mm per 300mm length. Our CNC machining maintains ±0.1mm diameter precision and 0.5mm/300mm straightness for optimal load distribution.

5. How do pin configurations differ by application?

Standard scaffolding pins utilize straight designs while cuplock systems require scaffold toggle pins with integrated locking mechanisms. Suspended scaffolds use specialized spring-loaded pins with secondary retention systems.

6. What environmental considerations apply?

Coastal environments require 500g/m² zinc coatings. Chemical plants benefit from epoxy-polyester hybrid coatings. Cold climates need impact-tested steel certified to -40°C. Our product range addresses all environmental challenges.

7. What documentation should accompany purchases?

Reputable scaffolding pins for sale include material certificates (MTC), test reports per EN 10204 3.1, galvanizing certificates, and production traceability. We provide complete documentation packages with QR code traceability for all shipments.

Performance Analysis

Load Distribution Efficiency

Failure Point Comparison

CANGZHOU WORLD CUP TRADING CO.,LTD.

Global leaders in formwork and scaffolding solutions with 15+ years specialized manufacturing experience. Our factory in China's industrial heartland produces premium construction components trusted by contractors worldwide.

Manufacturing Excellence

- ✓ 25,000 m² production facility

- ✓ ISO 9001 certified quality

- ✓ Automated CNC production

- ✓ 3-stage quality control

Contact Information

- Address: DEVELOPMENT AREA OF BOTOU, CANGZHOU CITY, HEBEI PROVINCE, CHINA

- Phone: 132 8320 1810

- Email: annie@wrkgroup.ltd

- Website: www.wrkformwork.com

- Product Link: Scaffolding Prop Pins

Industry Research Citations

-

"Material Improvements in Scaffold Connection Systems" - International Journal of Steel Structures, 2023

https://doi.org/10.1007/s13296-023-00725-3 -

"Failure Analysis of Construction Scaffolding Components" - Engineering Failure Analysis, Volume 146, 2023

https://doi.org/10.1016/j.engfailanal.2023.107103 -

Global Scaffolding Safety Report 2023 - Construction Industry Safety Council

https://www.constructionsafety.org/reports/global-scaffolding-safety-2023 -

"Advances in Corrosion Protection for Construction Hardware" - Materials Performance Journal, May 2023

https://www.materialsperformance.com/articles/material-selection-design/2023/advances-in-corrosion-protection

This is the first article

Latest News

-

Frame Scaffolding Pins | Heavy-Duty Construction Scaffolding | Buy TodayNewsJul.21,2025

-

Tiny Nuts and Bolts for Precision Projects Complete Nuts, Bolts, and Washers SetsNewsJul.08,2025

-

High Quality SS Bolt Nut Washer - Durable Fastening Solutions for IndustriesNewsJul.08,2025

-

High Quality Slotted Hex Nut – Durable M12 Hex Nut & Slotted Bolt Compatible FastenerNewsJul.07,2025

-

Best Shuttering Shikanja Price & Construction Materials – High Quality, Durable & AffordableNewsJul.07,2025