Aug . 16, 2025 05:20 Back To List

Reliable Rubber Waterstop for Concrete Sealing & Expansion Joints

The Critical Role of Rubber Waterstops in Modern Construction and Infrastructure

In the intricate world of civil engineering and construction, the integrity of concrete structures against water ingress is paramount. This necessitates the deployment of highly specialized sealing solutions, among which the rubber waterstop stands out as a foundational component. Designed to create a watertight seal in expansion, construction, and contraction joints, these flexible barriers are indispensable for preventing water from penetrating concrete structures, thereby safeguarding their longevity and structural stability. The evolution of waterstop technology has seen significant advancements, with materials like PVC and various rubber compounds offering distinct advantages tailored to specific environmental and structural demands. The market for waterstops, encompassing products like the high-performance PVC Ruber Waterbar, is continually expanding, driven by global infrastructure development and an increasing emphasis on resilient and sustainable building practices. Our focus delves deep into the technical nuances, application versatility, and strategic importance of these critical components, providing a comprehensive overview for engineering professionals and decision-makers in the B2B sector. We will explore the latest industry trends, dissect complex technical parameters, and illustrate the diverse scenarios where these solutions offer unparalleled protection, ensuring that structures remain impervious to water damage for their entire design life. From the bustling urban landscape to remote industrial sites, the application of robust waterstop solutions is a testament to meticulous engineering and foresight in construction. This analysis provides an authoritative guide to understanding, selecting, and implementing optimal waterstop technologies, crucial for maintaining the structural integrity and operational efficiency of complex infrastructure projects.

Industry Trends and Technological Evolution in Waterstop Solutions

The industry for waterstop solutions is characterized by continuous innovation, driven by stricter environmental regulations, increasing demands for structural longevity, and the emergence of advanced material science. A notable trend is the move towards high-performance polymers and specialized rubber compounds that offer superior durability and resistance to aggressive chemicals, extreme temperatures, and seismic activity. While traditional rubber waterstop remains a cornerstone, the prominence of the PVC water stopper has surged due to its excellent tensile strength, elongation capabilities, and resistance to acids, alkalis, and ozone. Furthermore, the development of the swellable waterstop, which expands upon contact with water to form a compression seal, represents a significant leap forward, offering an alternative or complementary solution, particularly in situations where conventional waterstops are challenging to install. There is also a growing emphasis on sustainable manufacturing processes and the use of recycled materials, aligning with global efforts to reduce environmental impact. Integration of Building Information Modeling (BIM) in project planning now facilitates precise waterstop placement, minimizing waste and optimizing structural design. Manufacturers are increasingly focusing on providing comprehensive technical support, including detailed installation guides and on-site assistance, recognizing that the performance of a waterstop is heavily reliant on proper installation. This holistic approach ensures that solutions like our PVC Ruber Waterbar meet not only current engineering standards but also anticipate future challenges in infrastructure development, reinforcing its position as a preferred choice for complex projects. The market is also witnessing a demand for customized waterstop profiles to accommodate unique joint designs and structural movements, pushing the boundaries of traditional product offerings and fostering greater collaboration between material scientists and civil engineers to develop bespoke solutions that address specific project requirements with unprecedented precision and efficacy.

Precision Manufacturing: The Core of Durable Waterstop Production

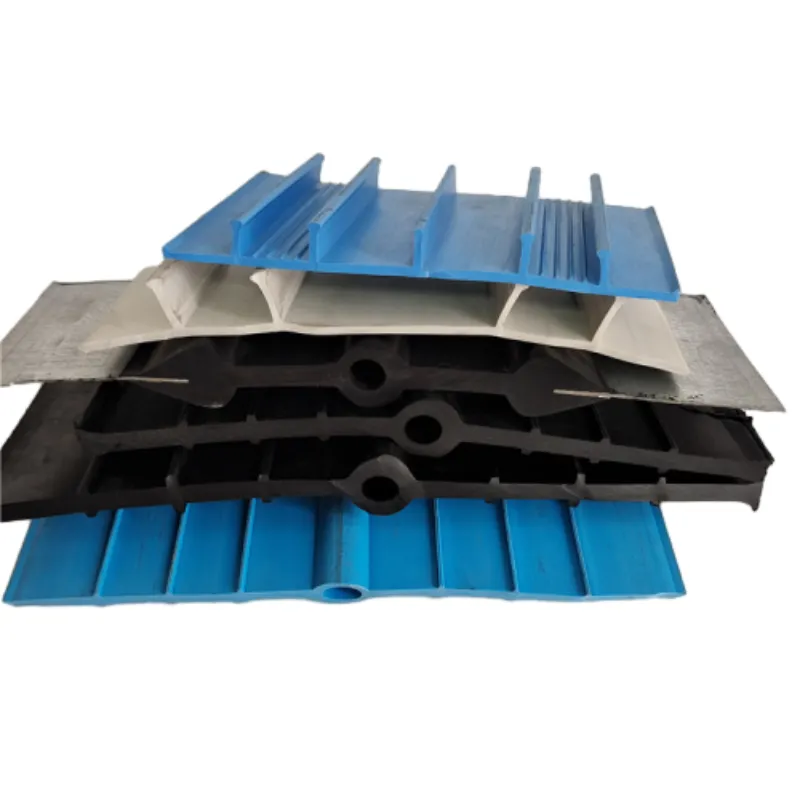

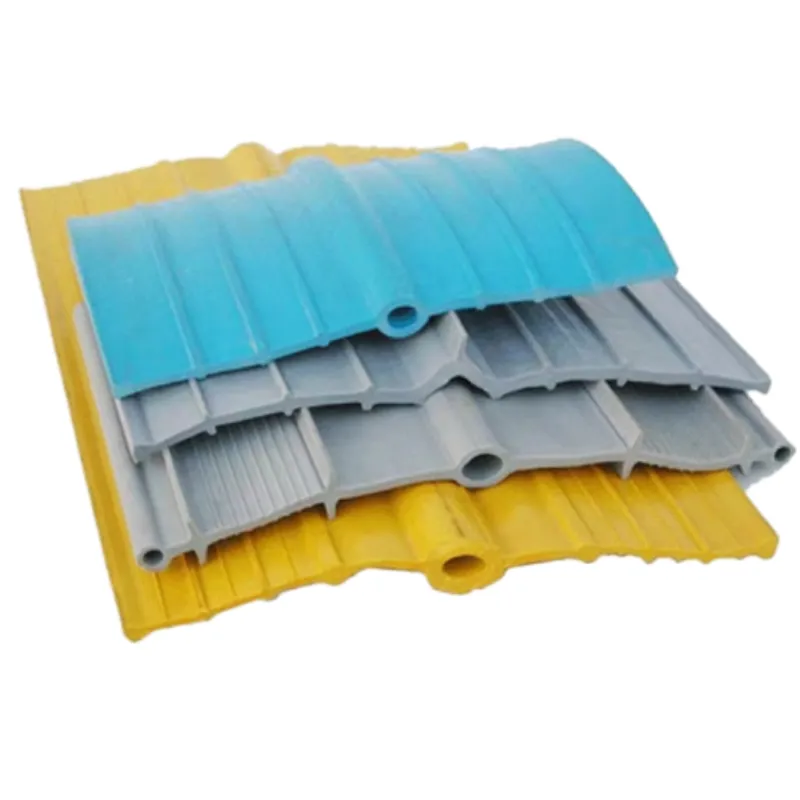

The manufacturing of a high-quality rubber waterstop, such as our PVC Ruber Waterbar, is a meticulously controlled process designed to yield products with consistent performance and exceptional longevity. It begins with the careful selection of raw materials, typically high-grade virgin PVC resin or specialized synthetic rubber compounds like SBR (Styrene Butadiene Rubber) or Neoprene, chosen for their inherent elasticity, tensile strength, and resistance to environmental degradation. The primary manufacturing technique employed for profiles like the PVC water stopper seal is extrusion. In this process, the selected polymer compound, often reinforced with additives to enhance UV resistance, fungal resistance, or fire retardancy, is fed into an extruder. Under precise temperature and pressure controls, the material is melted and forced through a die, which forms the continuous profile of the waterstop. This extrusion process ensures uniform thickness and consistent dimensions, critical for effective sealing performance. Following extrusion, the material is cooled and then cured, often through vulcanization for rubber-based products, which permanently sets the material’s shape and significantly enhances its physical properties, including resilience and durability. Each batch undergoes rigorous quality control, with samples subjected to mechanical testing to verify tensile strength, elongation at break, hardness (Shore A), and specific gravity, conforming to international standards such as ASTM D412, ASTM D2240, and ISO 9001 certifications. Furthermore, accelerated aging tests (e.g., exposure to UV radiation, ozone, and chemical immersion) are performed to predict long-term performance and ensure a projected service life exceeding 50 years under typical conditions. Applicable industries for such robust manufacturing include petrochemical facilities, metallurgical plants, and vital water supply and drainage systems, where leak prevention is non-negotiable. The advantages in these typical application scenarios include superior corrosion resistance, ensuring the integrity of structures exposed to aggressive chemicals, and preventing the wasteful energy consumption associated with water infiltration and subsequent remediation.

Essential Technical Parameters and Specifications of Rubber Waterstops

Selecting the appropriate rubber waterstop for any given project hinges on a thorough understanding of its technical specifications and performance characteristics. These parameters are crucial indicators of a waterstop's ability to withstand operational stresses, environmental exposures, and ensure long-term sealing efficacy. Key physical properties include tensile strength, which measures the maximum stress a material can withstand while being stretched or pulled before breaking, typically ranging from 10 to 15 MPa for high-grade PVC and rubber. Elongation at break, indicating the percentage increase in length before failure, is equally important for accommodating joint movements, with values often exceeding 300% for flexible compounds. Hardness, measured by Shore A durometer, defines the material's resistance to indentation, usually between 65-80 for standard waterstops, balancing flexibility with structural integrity. Specific gravity is used to determine material density and quality. For PVC water stopper size, standard widths can vary from 150mm to 350mm, with thicknesses typically between 4mm and 15mm, designed to accommodate different concrete pour depths and joint widths. Chemical resistance is evaluated against a range of substances, including acids, alkalis, oils, and industrial effluents, ensuring suitability for diverse applications like wastewater treatment plants. The operational temperature range, usually from -35°C to +80°C for PVC and even wider for certain rubber types, guarantees performance across various climatic conditions. Water absorption and tear resistance are also critical, preventing material degradation and ensuring durability under hydraulic pressure. These metrics, alongside adherence to recognized standards like ASTM D412 for tension testing and ASTM D2240 for hardness, provide a comprehensive framework for assessing a waterstop's fitness for purpose. Prospective buyers should meticulously review these parameters to ensure the chosen product, such as the PVC Ruber Waterbar, aligns perfectly with their project's specific engineering demands and long-term performance expectations. Understanding these detailed technical aspects ensures a well-informed procurement decision, mitigating risks associated with material failure and ensuring robust, leak-proof structural integrity over decades.

Typical Rubber Waterstop Technical Parameters (Based on WRK PVC Ruber Waterbar)

Versatile Applications and Unparalleled Advantages

The adaptability and robust performance of the rubber waterstop make it an essential component across an extensive array of construction and infrastructure projects, particularly where watertight integrity is paramount. Its primary function is to prevent fluid migration through concrete joints, making it indispensable for structures designed to contain or exclude water. Prominent applications include the construction of hydroelectric dams, where massive hydrostatic pressures demand flawless joint sealing; tunnels and subways, preventing groundwater infiltration that could compromise structural safety and operational efficiency; and wastewater treatment plants, requiring chemical resistance to corrosive industrial effluents. Furthermore, for foundational structures like basements and retaining walls, especially in areas with high water tables, the use of rubber waterstop for concrete is critical to prevent dampness, mold growth, and structural degradation. Nuclear power plants, bridge decks, canals, reservoirs, and swimming pools also heavily rely on these seals to maintain their long-term functionality. The advantages derived from employing high-quality waterstops like our PVC Ruber Waterbar are multifaceted. Firstly, they ensure superior waterproofing, effectively halting water ingress and egress, which is crucial for maintaining the intended purpose of the structure. Secondly, their inherent flexibility allows them to accommodate significant structural movements, including thermal expansion and contraction, differential settlement, and seismic activity, without compromising the seal. This flexibility prolongs the service life of the structure by mitigating stress on concrete joints. Thirdly, the excellent chemical resistance of materials like PVC ensures durability in corrosive environments, reducing maintenance costs and risks associated with material degradation. Lastly, by preventing water damage, these waterstops contribute indirectly to energy efficiency by reducing the need for dehumidification and repair work, and directly by maintaining the thermal envelope of a structure, leading to significant long-term operational savings and enhanced overall structural resilience against environmental factors. The strategic implementation of these advanced sealing solutions ultimately translates into safer, more durable, and more sustainable infrastructure worldwide.

Strategic Vendor Selection and Customization Solutions

The selection of a waterstop vendor is a critical decision that extends beyond mere product specifications; it encompasses a comprehensive evaluation of manufacturing capabilities, technical support, and commitment to quality and service. While numerous suppliers offer generic PVC water stopper products, discerning B2B clients prioritize partners who demonstrate deep expertise in material science and engineering, coupled with a proven track record of reliable delivery. Factors to consider include adherence to international manufacturing standards (e.g., ISO 9001), the availability of comprehensive product testing reports, and the ability to provide tailored solutions for complex project requirements. A specialist manufacturer, like WRK Formwork with its PVC Ruber Waterbar, not only offers a standard range but excels in providing bespoke customization options. This includes varying the PVC water stopper size (width, thickness, and profile geometry) to perfectly match unique joint designs, adjusting material compounds for specific chemical resistance or extreme temperature performance, and fabricating complex intersections or factory-welded assemblies to minimize on-site labor and ensure seamless integration. The PVC water stopper price, while important, should always be evaluated in conjunction with the total cost of ownership, including ease of installation, anticipated service life, and the potential costs associated with premature failure or remediation. A reputable vendor offers robust pre-sales consultation and post-sales support, including detailed technical drawings, installation training, and responsive problem-solving. Such a partnership ensures that the chosen rubber waterstop not only meets current project specifications but also provides long-term value, mitigating risks and contributing to the overall success and durability of the infrastructure. Collaborating with a manufacturer who views waterstops not merely as commodities but as engineered solutions tailored to precise demands, fosters trust and ensures optimal outcomes for even the most challenging construction endeavors, emphasizing performance, reliability, and cost-effectiveness over the entire lifecycle of the project.

Real-World Applications and Success Stories

The efficacy of a rubber waterstop is best demonstrated through its successful deployment in challenging real-world scenarios, where its performance directly impacts the long-term integrity and operational viability of critical infrastructure. Consider a large-scale underground subway tunnel project in a high-density urban area, frequently exposed to fluctuating groundwater levels and significant seismic activity. The construction joints within the pre-cast concrete segments required a robust and flexible sealing solution. Our PVC Ruber Waterbar, specifically designed as a high-performance PVC water stopper seal, was selected. Its high elongation capabilities and exceptional tensile strength, validated by extensive third-party testing, proved crucial in accommodating the dynamic movements of the tunnel lining. After five years of operation, inspections revealed zero water ingress, a testament to the waterstop's sealing prowess and the precision of its installation. Another compelling case involves a major dam construction in a subtropical region, where the concrete structure is subjected to immense hydrostatic pressure and aggressive chemical exposure from mineral-rich water. Here, a specialized PVC Ruber Waterbar with enhanced chemical resistance properties was implemented in the contraction joints. Post-construction monitoring confirmed that the waterstop maintained its integrity and elasticity, preventing any leakage and contributing significantly to the dam's operational efficiency and safety, a performance sustained over a decade, far exceeding initial client expectations. Furthermore, for a multi-story underground car park constructed adjacent to a river, preventing water infiltration was a primary concern. The selected PVC Ruber Waterbar’s unique profile, coupled with our technical team's on-site guidance for joint preparation and welding techniques, ensured a flawless installation. Feedback from the client highlighted the seamless integration and the complete absence of water issues even during periods of heavy rainfall, validating the product's performance and WRK Formwork's commitment to delivering reliable solutions. These examples underscore how tailored waterstop solutions, backed by technical expertise, deliver quantifiable results in safeguarding complex concrete structures against the persistent threat of water. These successes not only build trust but also serve as benchmarks for future large-scale engineering projects that demand uncompromised watertight integrity.

Ensuring Trust: Frequently Asked Questions, Delivery, and Warranty

Building and maintaining trust with our B2B clients is foundational to our operations, especially when supplying critical components like the rubber waterstop. We address common inquiries, provide clear information on logistics, and offer robust assurances to instill confidence in our products and services.

A1: Our standard lead time for PVC Ruber Waterbar is typically 10-15 business days for most standard profiles and quantities. For large-volume orders or highly customized specifications, we provide a precise lead time estimate upon order confirmation, factoring in material availability and production scheduling. Expedited options may be available upon request, subject to production capacity.

A2: We stand behind the quality of our PVC Ruber Waterbar products with a comprehensive 10-year limited warranty against manufacturing defects. This warranty covers material integrity and performance under normal application and installation conditions, ensuring that our products meet or exceed industry standards for durability and effectiveness. Specific warranty terms and conditions are provided with each quotation and order.

A3: Our commitment to quality is upheld through stringent quality control measures at every stage of production, from raw material sourcing to final product inspection. We operate under an ISO 9001 certified quality management system, and all products undergo comprehensive testing, including tensile strength, elongation, hardness, and chemical resistance tests, according to ASTM and ISO standards. Test certificates and material safety data sheets (MSDS) are provided with each shipment to verify authenticity and adherence to specifications. We also ensure full traceability of raw materials and production batches.

A4: Absolutely. Our team of experienced technical engineers offers extensive support, including detailed installation guides, best practice recommendations, and practical advice for welding and jointing the waterstop profiles on-site. For complex or large-scale projects, we can arrange for remote consultations or, where feasible, on-site technical assistance to ensure correct and efficient installation, maximizing the performance of our PVC Ruber Waterbar. Our goal is to partner with our clients to ensure flawless execution from planning to completion.

Authoritative References

- American Society for Testing and Materials (ASTM) International. "ASTM D412: Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension."

- International Organization for Standardization (ISO). "ISO 9001: Quality management systems—Requirements."

- Concrete Society. "Concrete Society Technical Report No. 34: Concrete Industrial Floors (4th Edition)."

- U.S. Army Corps of Engineers. "Engineering Manual EM 1110-2-2101: Seepage Analysis and Control for Dams."

- ACI Committee 350. "ACI 350.4R-04: Design Considerations for Environmental Engineering Concrete Structures."

This is the first article

Latest News

-

Different Types of Bolt Nuts: Find Perfect Fasteners HereNewsAug.15,2025

-

Premium Roofing Materials: Durable & Reliable Building SolutionsNewsAug.14,2025

-

Premium Concrete Form Ties: Secure & Efficient Formwork SolutionsNewsAug.13,2025

-

Aluminium Formwork Shuttering: Efficient & Reusable Concrete SolutionNewsAug.12,2025

-

Efficient Ground Beam Shuttering for High-Rise ConstructionNewsAug.11,2025