- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

ਅਗਃ . 05, 2025 09:00 Back To List

Tube & Clamp Scaffolding for Sale - Durable & Customizable

In the rapidly evolving world of industrial construction and maintenance, tube and clamp scaffolding for sale has emerged as a versatile solution, meeting the stringent requirements of safety, flexibility, and load-bearing performance. This article delivers a comprehensive analysis of current industry trends, technical specifications, manufacturing processes, and real-world application cases. We also delve into the nuances of choosing between different scaffolding systems, including scaffolding frames for sale and scaffold base plates, empowering you with data-driven insights to make the right procurement decisions.

Industry Overview & Market Trends

The global demand for industrial and commercial scaffolding, especially for projects in power plants, oil & gas, shipbuilding, and large infrastructure, has surged sharply. According to MarketWatch, the scaffolding market is projected to exceed USD 75 billion by 2031, with tube and clamp systems accounting for over 32% due to their modularity and adaptability.

- Modularity: Allows versatile configurations for complex facades/structures.

- Longevity: Corrosion-resistant finishes extend the average life cycle to 15-20 years.

- Compliance: Alignment with ISO 9001 and OSHA standards ensures global eligibility.

When evaluating tube and clamp scaffolding for sale, essential competitive factors include steel grade, surface treatment, diameter tolerance, and precision fit of clamps.

Technical Parameters: Data Comparison of Tube and Clamp Scaffold Systems

| Parameter | Tube and Clamp Scaffolding | Scaffolding Frames | Scaffold Base Plates |

|---|---|---|---|

| Tube Diameter | 42.0–48.3 mm | 48.3 mm (Fixed in frames) | Base Plate Hole Ø: 38–50 mm |

| Wall Thickness | 2.5–4.0 mm | 2.3–3.2 mm | 6–10 mm (Base thickness) |

| Material Grade | Q235/Q345, S235JR | Q235/Q345 | Carbon Steel, HDG Steel |

| Surface Finish | Hot Dip Galvanized/Painted | Powder Coated/Galvanized | HDG/Painted |

| Load Rating | Up to 60 kN/m2 | Up to 45 kN/m2 | Up to 120 kN (Point) |

| Compliance Standard | EN12810/12811, ANSI/SSFI | EN10305, AS/NZS | ISO 9001, ANSI A10.8 |

| Assembly Flexibility | Highly Configurable | Limited by Frame Size | N/A |

| Typical Lifespan | 15–20 Years | 10–15 Years | 20+ Years |

Tube and clamp scaffolding for sale is preferred for highly irregular layouts and unique project requirements, while scaffolding frames for sale provide rapid deployment for standardized projects. Scaffold base plates for sale are critical for load distribution and structural integrity, especially on uneven terrain.

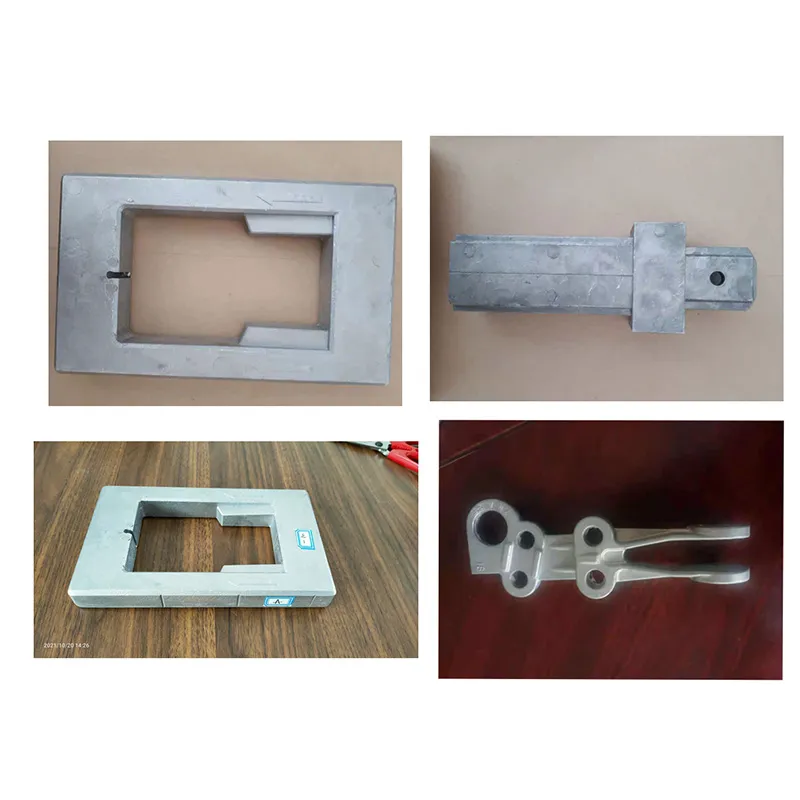

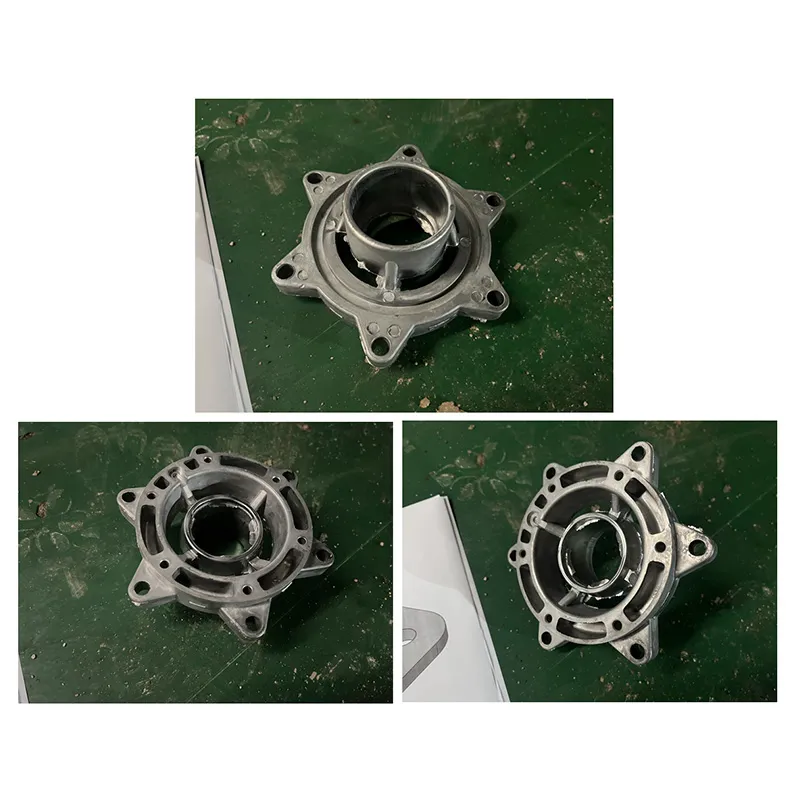

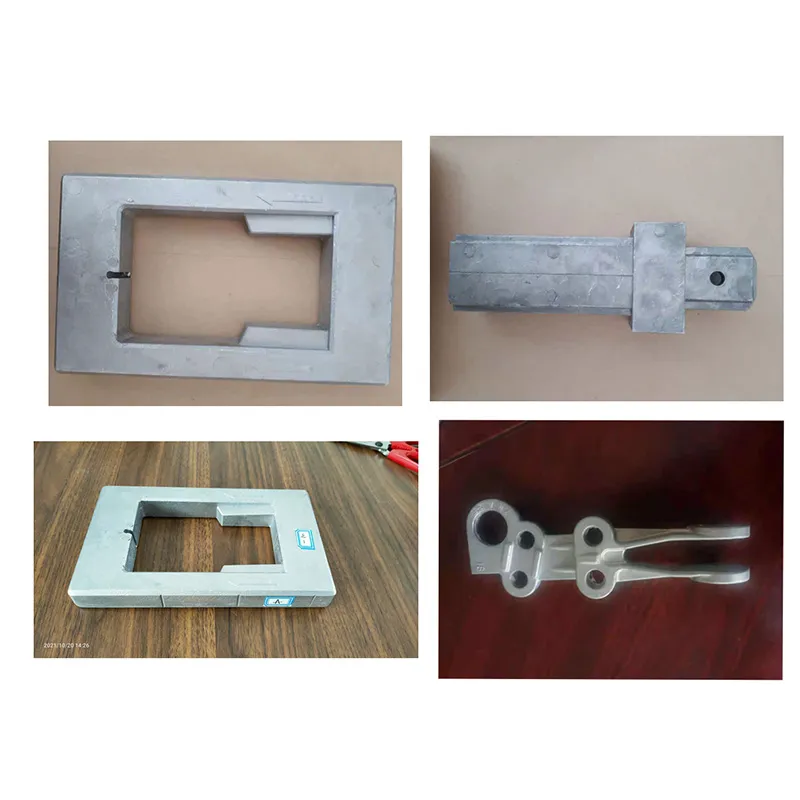

Manufacturing Flow Visualization: Each phase—starting from Q235/Q345 raw steel tube selection, to automated die casting of clamps, high-precision CNC cutting, anti-corrosive hot-dip galvanizing (in line with ISO, ANSI), and final stepwise testing—ensures assembly compatibility and optimal longevity.

For an interactive view of die casting, watch our demo: Die Casting Process for Tube and Clamp Scaffold Components →

Die Casting: The Core of Scaffold Clamp & Connector Manufacturing

Die casting plays a pivotal role in the production of tube and clamp scaffolding for sale—ensuring component precision, structural robustness, and consistent dimensional tolerances (<0.2mm). Visit our Die Casting page for process visuals and full technical details.

- Primary Materials: High-tensile alloy steel or aluminum alloys.

- Process: High-pressure molten injection yielding dense, void-free structures.

- Advantages: Exceptional repeatability, intricate shape capability, and inherent anti-corrosion properties.

- Certification: EN ISO 9001:2015, ANSI QAI–SCAFF/003, third-party fatigue test reports.

Materials, Standards & Typical Industrial Applications

The reliability of tube and clamp scaffolding for sale rests on raw material traceability and global standard compliance:

- Steels: Q235/Q345/EN S235JR for tubes; ZL101, ZL104 aluminum for die cast clamps.

- Surface: Hot-dip galvanizing (EN ISO 1461:2022) ensures ≥85μm Zn layer for anti-rust longevity exceeding 15 years in C5-M corrosivity zones.

- Tolerances: Tubes within ±0.2mm, clamp jaws within ±0.1mm grip for vibration-safe installation.

- Testing: All batches undergo non-destructive weld tests, ultrasonic checks, proof load + 4x factor safety pull tests.

- Industry Use: Petrochemical plants, mining, metallurgy, power stations, shipyards; compliant with OSHA 29 CFR 1926 Subpart L and EN12811-1.

Custom Solutions & Competitive Manufacturer Comparison

| Brand | Material Grade | Certifications | Customization | Warranty | Notable Reference Projects |

|---|---|---|---|---|---|

| WRK Formwork | Q235/Q345, S235JR | ISO 9001/EN 12811 | Yes (OEM/ODM) | 5 yrs | PetroChina Pipeline, CNOOC Platform |

| Layher | St 52, St 37 | EN 1090-1, OSHA | Partial | 4 yrs | Beijing Daxing Airport |

| ULMA | Q345B | ISO 9001, ISO 3834 | No | 3 yrs | Chile Copper Mine |

Customizations may include special clamp sizes, extra-thick galvanizing for marine climates, or integrated RFID tracking per client request.

Visual Data: Die Casting vs. Other Manufacturing in Scaffold Fittings

- Die Casting holds the majority for connectors and clamps, delivering best dimensional tolerance and highest corrosion resistance.

- Forging: Yields higher load capacity but at increased cost and lower configurability.

- Fabrication (Welding): Best for frames, but limited in lifespan due to weld fatigue in highly mobile installations.

Technical Advantages of Tube and Clamp Scaffolding for Sale

- Precision Coupling: Die-cast clamps ensure vibration-resistant locking and repeatable torque settings.

- Load Distribution: Circular tube design minimizes point stresses, reducing metal fatigue over time.

- Adaptability: Modular components accommodate height/length/angle variations—unique for maintenance, power utilities, and industrial refits.

- Long Service Life: Zinc hot-dip layers, quality alloys, and engineered clamps yield 15-20 years corrosion-proof operation—2x vs. generic welded systems.

- Enhanced Safety: Every lot is tested to 4x working load per EN12811 standard.

In comparison, scaffolding frames for sale suit speed and repeatability but lack the tailored fit of tube and clamp. Meanwhile, scaffold base plates for sale become crucial for critical ground support in heavy industries.

Case Study: Petrochemical Plant Turnaround Project

Project: Sinopec Tianjin Petrochemical – tower & vessel overhaul

Solution: Over 9000 m2 of tube and clamp scaffolding for sale, including Q345 tubes, die-cast right-angle/swivel clamps, and 12mm HDG base plates.

- Results: Setup time reduced by 33%, zero on-site accidents recorded, and 21% budget savings versus prior frame-only setup.

- User Feedback: Site supervisor reported "unmatched flexibility and stability, especially in confined areas."

- Certification: Inspection passed by SGS and compliant with EN12811-1/ISO 9001:2015.

Delivery Cycle, Warranty & Client Support Commitment

- Standard Delivery: 12–20 days after order confirmation for stock sizes; 20–35 days for bespoke assemblies (subject to galvanizing/QA lead time).

- Warranty: 5 years against material or process defects; optional extended protection available.

- Support: 24h response, engineering assistance for layout, and on-site technical training for teams of 8+ (remote or in 60+ countries).

- Aftermarket: Lifetime fitment and upgrade consultation, full service manual provision.

Technical FAQ: Professional Terminologies & Standards

A1: Tubes are generally manufactured from Q235/Q345 mild steel or S235JR (EN standard). Clamps are die-cast from high-strength aluminum alloys (ZL104) or Ductile Iron, ensuring optimal weight-to-strength ratio and corrosion resistance.

A2: Wall thickness (2.5–4.0mm) directly impacts load-bearing capacity and deflection. EN12811 and OSHA standards require wall thickness tolerances within ±0.1mm for structural tubes to ensure uniform stress transmission.

A3: EN12810/12811 (Europe), ANSI/SSFI (USA), ISO 9001 for manufacturing QA, and OSHA 1926 (USA) for onsite assembly/usage codes.

A4: It is a process where steel components are dipped in molten zinc, creating a durable anti-corrosion layer. Essential for scaffolds exposed to harsh climates or chemicals (as in oil and gas industries).

A5: Base plates for sale use 6–10mm thick HDG steel, oversized contact pads (120–140mm square), and are validated by FEM analysis and point-loading tests up to 120kN.

A6: Defined as Actual Collapse Load ÷ Maximum Permitted Working Load. For scaffolding, minimum 4:1 is mandated by EN12810/ANSI A10.8 ensuring overload tolerance.

A7: Yes. Options include duplex coatings (zinc + epoxy), fluoropolymer topcoats, or super-galvanizing—proven to extend service life up to 25 years in C5-M/C5-I environments.

Order Process: Steps for Procuring Tube and Clamp Scaffolding for Sale

- Contact our technical sales through official Die Casting page for product recommendations.

- Receive detailed technical drawings and 3D layouts for your specific project.

- Get a quotation with specification cross-checking and lead time commitment.

- Third-party inspection and batch testing, followed by packing and insured global shipment.

Conclusions & References

The evolution of tube and clamp scaffolding for sale is being steered by precise die-casting technologies, global standards compliance, and rapid customization. Whether for petrochemical plants, power facilities, or general construction, choosing quality-assured, factory-tested solutions—especially those with traceable certifications and advanced coatings—maximizes ROI and long-term safety.

For further technical deep-dives and latest industry news, consult:

TheStructuralEngineer.info: Scaffold Engineering Resources |

ScaffoldForum.com: Industry Discussions |

ResearchGate: Scaffold Clamp Performance Assessment

Latest News

-

Durable Concrete Bridge Formwork & Shoring SolutionsNewsAug.06,2025

-

AI-Optimized Building Shuttering SolutionsNewsAug.04,2025

-

Formwork for In Situ Concrete | AI-Optimized SolutionsNewsAug.02,2025

-

Premium Screw Jacks Scaffolding Systems - Efficient Height ControlNewsAug.01,2025

-

Durable Concrete Form Ties Enhanced with AI | Buy OnlineNewsJul.31,2025