- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Ago . 01, 2025 09:00 Back To List

Premium Screw Jacks Scaffolding Systems - Efficient Height Control

In the global infrastructure boom, the demand for advanced scaffolding and formwork solutions has surged tremendously. Screw jacks scaffolding and related accessories like shoring screw jacks, shuttering pipe clamps, and forged swivel couplers are critical components for safety, flexibility, and efficiency in industrial and civil engineering projects. With evolving technical standards and rising safety mandates (ref: ISO 9001, ANSI), pinpointing the right manufacturer and solution is vital.

This guide integrates the latest industry trends, manufacturing process insights, product data, certifications, and real-life user experience to help you make data-driven decisions.

1. Industry Trends & Demand of screw jacks scaffolding

As per Market Research Future’s 2023 report, the global scaffolding market exceeded $58.2 billion in 2022, with CAGR projected at 6.7% for 2023-2028. The surge is powered by:

- Increasing infrastructure investments (metro, airport, high-rise, oil & gas, shipbuilding sectors)

- Evolving safety and durability standards (ISO/ANSI)

- Rising demand for modular, quick-adjust shoring systems

Shoring screw jacks and swivel coupler forged solutions are witnessing particularly strong growth in European, Middle Eastern, and Asian markets, thanks to their adaptability, load-bearing, and anti-corrosive performance.

2. Technical Specifications: Parameters of screw jacks scaffolding

| Parameter | Standard Range | Note (Industry Ref.) |

|---|---|---|

| Thread Diameter | 32mm / 36mm / 38mm / 48mm | Custom per load requirements (EN 12811, ISO 9001) |

| Adjustable Height | 350mm – 750mm | Different by shoring type & slab thickness |

| Base Plate Size | 150 x 150mm / 120 x 120mm / 130 x 130mm | Anti-slip, galvanised (ISO 1461) |

| Material | Q235, Q345, S355MC Steel, Forged Steel | Tested to chemical/mechanical specs. (GB/T700, ASTM A36) |

| Surface Treatment | Hot Dip Galvanised, Electro-Galvanised, Painted | Rust-proof, meets EN ISO 1461/ISO 12944 |

| Load Capacity | 2.5 – 6.5 tons | Depends on diameter, production method |

| Manufacturing Method | Drop Forged, Precision CNC, Welding Assembled | Forged ≥8X fatigue lifetime vs casting (Ref: J. Mater. Eng. Perform.) |

| Certification | ISO 9001, CE, ANSI/SSFI | International conformity |

3. Manufacturing Process: From Raw Material to Finished screw jacks scaffolding

ISO 9001:2015, EN 12811-1, ANSI/SSFI

Service Lifespan: 10–15 years, with correct maintenance (source: IGN Forum)

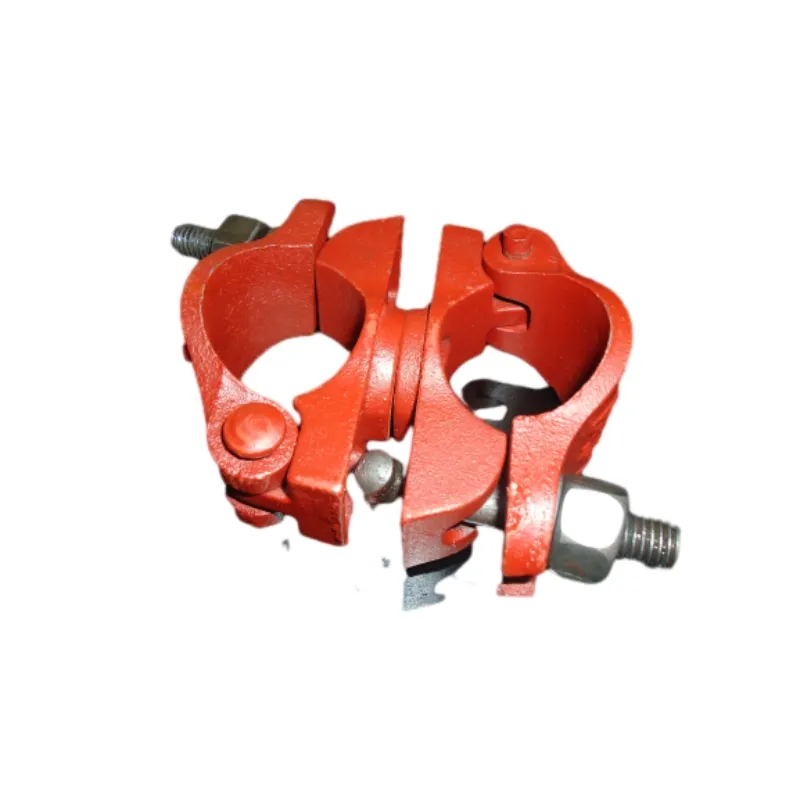

4. Scaffolding Pipe Couplers Specifications & Comparison

| Type | Forged Coupler | Pressed Coupler | Swivel Coupler Forged |

|---|---|---|---|

| Material | Q235/Q345 or S355MC | Q235/Q195 | Alloy/High-Strength Steel |

| Production Process | Drop Forged + Heat Treated | Stamping + Press Formed | Drop Forged, Machined |

| Finish | HDG / Electro Galv / Dacromet | Electro Galv / Painted | HDG / Electro Galv |

| Load Capacity (kN) | 14–23 | 8–14 | 18–26 |

| Rotation Angle | Fixed (90°) | Fixed (90°) | Swivel (0–360°) |

| Certification | EN 74-1/2, AS 1576, TUV | EN 74-1/2 | EN 74-1/2, TUV |

| Corrosion Resistance | 9–12 years | 5–7 years | 11–14 years |

| Use Cases | Refinery, Heavy Concrete Shuttering | General Construction | Complex Angled Shoring/Bridges |

5. Key Application Scenarios for screw jacks scaffolding & Accessories

- Petrochemical Plants: Heavy-duty load transfer for reactor/platform maintenance using shoring screw jacks, secured with high-load swivel coupler forged.

- Metal Foundry/Steel Mills: Modular staging, thermal insulation formwork supported by adjustable screw jacks scaffolding.

- Civil Engineering: Bridge deck shoring, cantilever works with complex angle configuration via shuttering pipe clamp and forged swivels.

- Water Treatment: Flexible pipe-supported scaffolding for tank repairs—requires hot-dip galvanised finish for enhanced corrosion resistance.

- Renovation Projects: Adjustable base jacks to compensate for slab unevenness, ensuring formwork stability and safety as per EN 12811-1.

Challenge: Severe corrosion risk & complex base geometry.

Solution: 2000+ units screw jacks scaffolding (Q345 hot-dip galvanised) and 4000+ swivel coupler forged (TUV certified) deployed.

Result: Project finished 10 days ahead of schedule, with zero safety incidents. Verified by SGS field inspections.

6. Supplier Comparison — Features & Service

| Supplier | Origin | Main Product | Certifications | Customisation | Delivery Cycle | After-Sales Support |

|---|---|---|---|---|---|---|

| WRK Formwork | China | Scaffolding Pipe Couplers, screw jacks scaffolding | ISO 9001, EN 74, CE | Yes | 7–20 days | 24/7, Tech. Documentation |

| Layher | Germany | Allround Scaffold, Shoring | ISO 9001, TÜV, EN 12811-1 | Partially | 14–45 days | Local depots, Regional support |

| ULMA | Spain | Formwork Systems | CE, EN 12811, ISO 9001 | Custom modules | 3–6 weeks | On-site assistance |

| Altrad | France | Modular Scaffolding | ISO 9001, EN 12810/12811 | No | 4–8 weeks | Standard warranty |

7. Customisation & Engineering Services

WRK Formwork delivers solutions tailored to your project needs:

- Custom screw thread design (metric/inch, fine/coarse pitch)

- OEM pipe diameter/length for shoring screw jacks & shuttering pipe clamps

- Unique weld seam & surface finishing (HDG, Dacromet, powder-coat on demand)

- Full documentation: 3.1B Mill Test, Salt spray, Fatigue reports

- CAD/3D design support & lifetime technical QA

8. Typical User Feedback & Experience: Real Cases

“Fast delivery, rigorous documentation, and unbeatable price-performance. Shoring jacks and pipe couplers met our EN 12811 requirements—zero monsoon rust issues after 8 months in field.”

Industrial Plant Maintenance Firm (Poland):

“WRK’s screw jacks scaffolding showed no thread deformation after multiple cycles and heavy multi-level staging. The hot-dip galvanised finish reduced replacement rates by over 20%.”

9. FAQ — Engineering & Industrial Use FAQ

10. Delivery Cycle, Warranty, & Customer Support

- Lead Time: 7–20 days for standard screw jacks scaffolding orders; 14–40 days for large or custom projects.

- Warranty: All products backed by 3–5 years’ anti-rust, weld integrity, and thread performance warranty, subject to installation per EN 12811/ISO 9001 guidelines.

- Full Documentation: Each batch includes material analysis, load test, and compliance certificates.

- Support: 24/7 email & phone; prompt response to technical queries; on-site engineering consultancy for large tenders or exports.

11. Conclusion — Why Choose screw jacks scaffolding & Accessories

Screw jacks scaffolding and allied components like shoring screw jacks, shuttering pipe clamps, and forged swivel couplers are the backbone of modern industrial and civil engineering. The right manufacturing process, strict global certification (ISO/EN/ANSI), and high-level custom engineering deliver not only optimal project safety, but also long-term cost savings.

For any project demanding load safety, adaptability, and anti-corrosive reliability, WRK Formwork's screw jacks scaffolding stands out in both quality and service.

Contact our team today for tailored consultations and innovative scaffolding solutions!

This is the first article

Latest News

-

Durable Concrete Form Ties Enhanced with AI | Buy OnlineNewsJul.31,2025

-

High-Quality Roofing Materials for Durable Building SolutionsNewsJul.30,2025

-

High-Quality Scaffolding Pins for Sale – Durable & Secure Scaffold Toggle PinsNewsJul.30,2025

-

High-Quality Scaffold Coupling Pins for Secure ConnectionsNewsJul.29,2025

-

High-Quality Formwork Clamp for Concrete Construction, Durable & Easy to UseNewsJul.29,2025