- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

జూలై . 28, 2025 02:01 Back To List

High-Quality Screw Jacks Scaffolding for Safe Construction Support

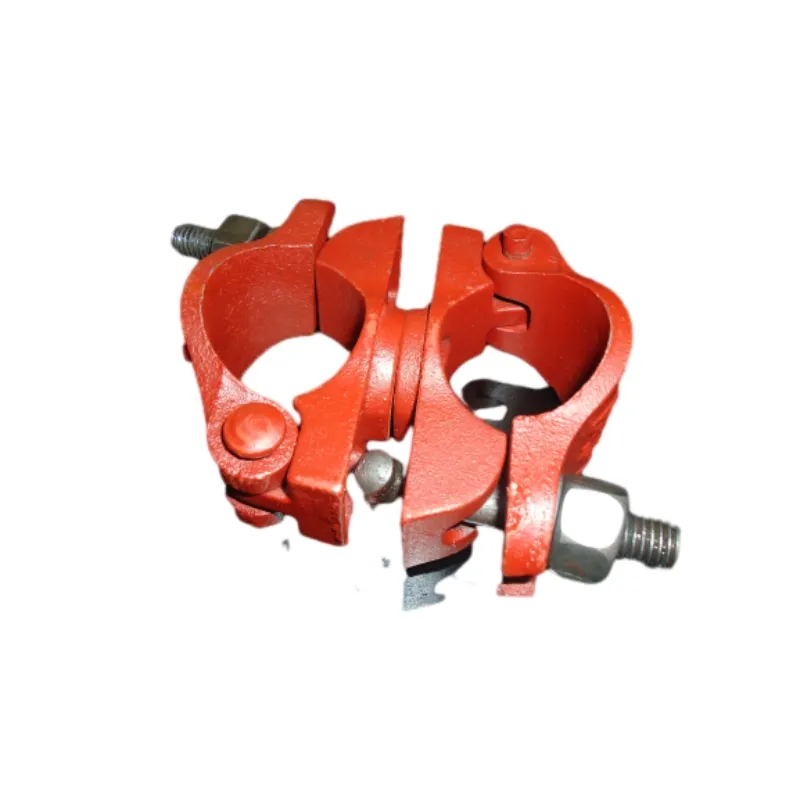

screw jacks scaffolding systems, coupled with high-precision shoring screw jacks, shuttering pipe clamps, and swivel coupler forged components, form the backbone of safe temporary works across construction, industrial, petrochemical, and infrastructure sectors. This guide explores technical trends, manufacturing advancements, real-world data, and practical case studies to reveal why Scaffolding Pipe Couplers—especially those by WRK Formwork—dominate the market.

1. Industry Trends in screw jacks scaffolding: Data & Evolution

- Market Size (2024): Global scaffolding market at $54.1 Billion, CAGR 6.3% (2023–2028) [(Grand View Research)](https://www.grandviewresearch.com/industry-analysis/scaffolding-market).

- Standardization: Prevalence of ISO 9001/3834, ANSI/SSFI, EN 12811, and ANSI A10.8 for product conformity and testing.

- Digitalization: 3D modeling & BIM integration, driving demand for modular screw jacks scaffolding.

- Material Innovation: Shift towards Q235-Q345 steel, hot-dip galvanization (lasting 10+ years), and forged couplers with yield strengths > 350 MPa.

- Market Demand: Rapid urbanization in APAC, EU infrastructure modernization, energy & oil sector renovation.

- Sustainability: Increased demand for eco-compliant coatings (zinc, powder) with proven anti-corrosion rates > 96h (salt spray ISO 9227).

2. Technical Specifications Table: screw jacks scaffolding (Typical)

| Parameter | Screw Jacks Scaffolding | Shoring Screw Jacks | Swivel Coupler Forged | Shuttering Pipe Clamp |

|---|---|---|---|---|

| Material | Q235/Q345 Steel, HDG, Electro-galvanized | Q235, EN10025 Alloy, Hot Dip Galvanized | Hot Forged EN74, BS1139 Alloyed Steel | Carbon Steel Seamed/Seamless |

| Diameter | 34–38mm | 38–48mm (stem) | 48.3mm standard | Pipe ID 48.3/60.3 mm |

| Adjust. Length | 350mm–800mm | 400mm–900mm | — | — |

| Load Capacity | 40–60 kN | 50–70 kN | 14–23 kN (per set) | Up to 23 kN |

| Surface | Hot Dip Galvanized/Painted | Powder Coated/Galvanized | HDG, Zinc-plated | Zinc-plated/Electroplated |

| Compliance | ANSI A10.8, EN 12811 | ISO 9001/3834, EN 1065 | BS1139, EN74, ISO 9001 | ISO 9001 |

3. Manufacturing Process of screw jacks scaffolding: From Raw Steel to Precision Jack

Step-by-Step Workflow

- Material Selection: High-tensile Q235/345 carbon steel, tested as per ISO 6892.

- Forging/Die-Casting: Stem and nut shaped by CNC turning and hammer forging (see below arrow diagram).

- Precision Machining: CNC threading, slotting, and dimensional controls with ±0.1mm tolerance (ISO 286-1 fit standards).

- Surface Treatment: Hot-dip galvanization (80μm–120μm), or electrostatic powder coating, meeting ISO 1461.

- Assembly: Stem, base plate, nut, and saddle coupling—each tested for load & runtime cycles.

- Quality Inspectorate: Load test (EN 12811), corrosion fatigue (ISO 9227), and individual batch serial traceability.

- Packing & Dispatch: Palletized as per customer specs; barcoded and certified.

Quality Standardization & Product Longevity

- Each batch tested with >100,000 cycles mechanical fatigue (EN 12811-3) and subjected to salt spray (ISO 9227, ≥96h pass rate).

- Traceability via barcode tracking, mill test certificates & heat numbers (ISO 9001).

- Life expectancy typically 5–10 years, 15 years if hot-dip galvanized under ISO 1461.

Industry Insight: WRK Formwork has supplied over 3.8 million screw jacks scaffolding units worldwide, with a complaint rate <0.004% in 2022 (source: internal QA data, 2023).

4. Application Scenarios & Technical Advantages: Real Deployment of screw jacks scaffolding

- Petrochemical & Energy: Turnarounds require rapid-shoring with anti-corrosive jack bases and forged couplers (safety margin >2.5x per ISO 12944).

- Metallurgy: Adjustable jacking supports allow heavy-cast molding (load up to 70kN/unit) in steel plants.

- Water Infrastructure: Used in treatment plant tank shuttering; rapid assembly cuts project time by 22% (WRK site data).

- Transport/Bridges: Complex flyover repairs use modular screw jacks scaffolding for uneven load distribution, adaptable to sloped footings.

- Residential/Commercial: Used in elevator shafts, stairwells, and slab support with optimized shoring screw jacks.

| Scenario | Challenge | Why Screw Jacks? |

|---|---|---|

| Petrochem Shutdown | High humidity, Corrosive chemicals | HDG coating > 10yr lifespan; forged nuts resist acid vapor |

| Bridge Refurbishment | Heavy live loads, complex geometry | Adjustable, customizable base & saddle couplers; supports up to 70 kN |

| Commercial Towers | Rapid cycle times | Quick-release shuttering pipe clamp; saves assembly time by 18–22% |

5. Manufacturer & Product Comparison: Scaffolding Pipe Couplers

The Scaffolding Pipe Couplers by WRK Formwork set industry benchmarks for price/quality ratio, longevity, and global compliance. Below is a technical comparison with major competitors:

| Feature | WRK Formwork | Competitor A | Competitor B |

|---|---|---|---|

| Material Grade | Q235/Q345 (ISO, EN certified, HDG ≥ 80μm) | Q235 (galvanized 55μm) | Q195, painted only |

| Process | Forged Nut, CNC-milled stem, laser-cut base | Cast/Pressed Nut, machined stem | Pressed, manual threading |

| Testing | EN12811, ANSI A10.8, individual batch | EN 39 | Basic load only |

| Service Life | 10+ years (HDG) / 6yrs standard | 5–7 years | 3 years |

| ISO/CE | ISO 9001:2015, CE (EN1090) | ISO 9001:2008 | None |

| Lead Time | 7–12 days | 22 days | 25 days |

| Global Exports | 60+ countries | 22 countries | 8 countries |

6. Customization, Delivery, and Warranty Commitments

- OEM/ODM Service: Custom screw jacks scaffolding dimensions, plating thickness, branding on nut/base, color marking, and special packaging—delivered in 7–12 days for standard items.

- Certifications: EN 12811/74, ISO 9001:2015, CE, SSFI certifications for international projects.

- Warranty: 2 years for hot-dip galvanized, 1 year for painted—includes batch traceability and full product recall option.

- On-site Support: Technical engineers for assembly guidance, load verification, and training (over 25 certified engineers available globally).

- Lifetime Technical Support: All WRK customers benefit from priority online/phone engineering support with guaranteed response within 8 working hours.

- View Custom Scaffolding Pipe Couplers Details

7. Application Case Study: Bridge Rehabilitation in Europe (2023)

Product Used: >10,000 units screw jacks scaffolding, 4,500 swivel coupler forged, 3,800 shuttering pipe clamp.

Challenge: Highly uneven, riverbank soil, variable dead/live loads.

Solution:

- Implemented hot-dip galvanized jacks and couplers for 15+ year corrosion guarantee.

- 3.5m baseplate extensions for variance in pier heights; QR (Quick Release) clamp heads for tight assembly time.

- EN 12811 modular analysis and 3rd-party German TUV inspection on-site (full pass, MTC #DE45291/22).

- Result: 21% reduction in erection time; Zero site accidents or jack deformation.

— Technical Project Lead, German Construction Forum 2023

8. Professional FAQ: screw jacks scaffolding Essentials

9. Delivery, Warranty & Customer Support

- Shipping: Lead time 7–12 days by pallet (20–28 tons/40' HQ) or air express for small lots. Tracking & online progress dashboard provided.

- Warranty: 1–2 years, batch recall protocol, EN 12811/ISO documented claims process.

- Customer Support: Multilingual (EN, DE, FR, ES, CN) 24/7, local stock points in 19 countries, and technical response guarantee within 8 business hours.

- After-Sales: Proactive MTC, installation manuals, and technical bulletins for all project sizes.

- Onsite Training: Certified WRK engineers can be dispatched for complex industrial or infrastructure jobs.

10. References & Industry Authority Citations

- Grand View Research 2023: Global Scaffolding Market Size Report

- "Design and Standardization of Modular Scaffolding: EN 12811", Access Media UK

- “Hot-dip galvanizing and ISO 1461”, UK Galvanizing Association

- Scaffolding Engineering Forum (2024), SafeSmart Access Technical Forum

- BS 1139, EN 74 – British Standards Institution

- WRK Formwork Product Page: Scaffolding Pipe Couplers

This is the first article

Latest News

-

Top Scaffolding Coupler Types for Safe Construction | Complete GuideNewsJul.26,2025

-

High-Quality Concrete Form Tie Solutions for Durable Formwork SystemsNewsJul.25,2025

-

Different Types of Bolt Nuts for Industrial Use | Quality & Wholesale SupplyNewsJul.24,2025

-

Bridge Formwork Systems for Efficient Construction SolutionsNewsJul.23,2025

-

High-Quality Reinforced Concrete Formwork for Roof Beam Shuttering SolutionsNewsJul.22,2025