- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

ఫిబ్ర . 04, 2025 02:09 Back To List

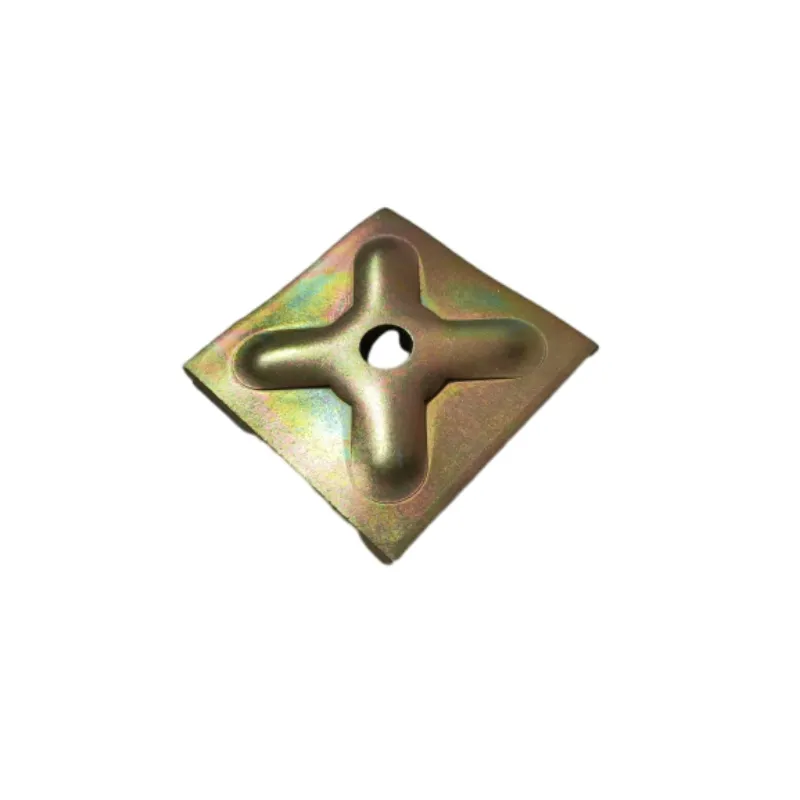

scaffolding parts

Scaffolding parts are a critical component of construction projects, serving as the backbone for safe and efficient building practices. For those who have ever walked past a construction site, scaffoldings are the towering structures enveloping incomplete buildings, providing both workers and materials with safe transportation and access to various heights. Understanding the true essence of these parts requires real-world experience, a profound grasp of scaffolding components, and a keen insight into the construction industry's evolving needs.

Trustworthiness in the scaffolding parts domain stems from reconciling impeccable product quality with transparent supply chain practices. Companies involved in manufacturing scaffolding parts must be transparent about their sourcing of raw materials, commitment to sustainable practices, and adherence to quality checks and tests. Brands that express a consistent track record of reliability instill confidence in their clients, assuring them that the products being used meet all prescribed standards. Pioneers in the field dedicate resources to research and development, refining scaffolding components to adapt to more challenging and complex construction environments. From high-rise buildings needing ultra-stable scaffolds to intricate artistic structures requiring flexible designs, the world of scaffolding parts is ever-evolving. This evolution is led by an unyielding commitment to safety, efficiency, and environmental consciousness. Bringing these elements together, an ideal scaffolding setup involves selecting parts manufactured by trusted brands, adhering to rigorous quality and safety regulations, and being assembled by trained and experienced personnel. The synergy between these facets ensures scaffolding parts support the construction industry not just as physical entities but as crucial contributors to the sector's safety, efficiency, and future-readiness. In conclusion, scaffolding parts are more than just building components; they represent an amalgamation of engineering mastery, regulatory compliance, and safety prioritization. Their role in supporting the construction industry is irreplaceable, with each part playing a pivotal role in the safety and efficiency of construction projects worldwide.

Trustworthiness in the scaffolding parts domain stems from reconciling impeccable product quality with transparent supply chain practices. Companies involved in manufacturing scaffolding parts must be transparent about their sourcing of raw materials, commitment to sustainable practices, and adherence to quality checks and tests. Brands that express a consistent track record of reliability instill confidence in their clients, assuring them that the products being used meet all prescribed standards. Pioneers in the field dedicate resources to research and development, refining scaffolding components to adapt to more challenging and complex construction environments. From high-rise buildings needing ultra-stable scaffolds to intricate artistic structures requiring flexible designs, the world of scaffolding parts is ever-evolving. This evolution is led by an unyielding commitment to safety, efficiency, and environmental consciousness. Bringing these elements together, an ideal scaffolding setup involves selecting parts manufactured by trusted brands, adhering to rigorous quality and safety regulations, and being assembled by trained and experienced personnel. The synergy between these facets ensures scaffolding parts support the construction industry not just as physical entities but as crucial contributors to the sector's safety, efficiency, and future-readiness. In conclusion, scaffolding parts are more than just building components; they represent an amalgamation of engineering mastery, regulatory compliance, and safety prioritization. Their role in supporting the construction industry is irreplaceable, with each part playing a pivotal role in the safety and efficiency of construction projects worldwide.

Next:

Latest News

-

Premium Roofing Materials - AI-Optimized by GPT-4 TurboNewsAug.03,2025

-

Formwork for In Situ Concrete | AI-Optimized SolutionsNewsAug.02,2025

-

Premium Screw Jacks Scaffolding Systems - Efficient Height ControlNewsAug.01,2025

-

Durable Concrete Form Ties Enhanced with AI | Buy OnlineNewsJul.31,2025

-

High-Quality Roofing Materials for Durable Building SolutionsNewsJul.30,2025

-

High-Quality Scaffolding Pins for Sale – Durable & Secure Scaffold Toggle PinsNewsJul.30,2025

Products categories