- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jul . 30, 2025 01:20 Back To List

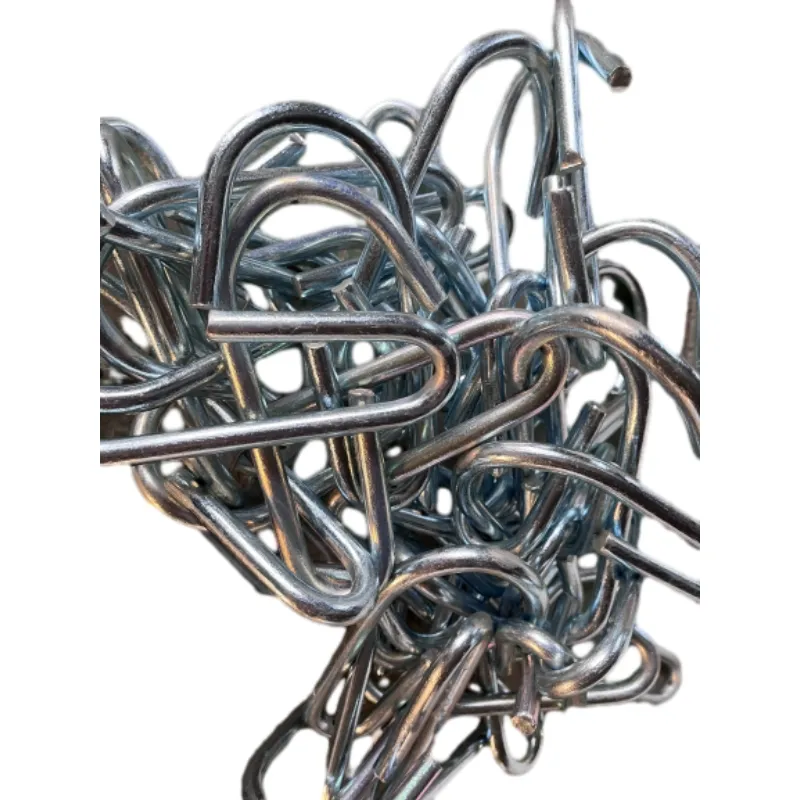

High-Quality Scaffolding Pins for Sale – Durable & Secure Scaffold Toggle Pins

In the dynamic construction and industrial sector, scaffolding pins for sale have become a critical focus for safety, efficiency, and reliable structural support. This in-depth guide explores everything from industry trends, technical specifications, and manufacturing processes, to real-world application cases, ensuring your project stays at the forefront of technology and safety.

Explore our featured product: Scaffolding Prop Pins — engineered for performance, versatility, and durability.

1. Industry Trends in Scaffolding Pins

The global demand for scaffolding pins for sale has surged due to growing infrastructure projects, rigorous safety standards, and advancements in material sciences. Recent data from Market Research Future projects a CAGR of 5.3% in the scaffolding sector between 2022-2028, significantly driven by modular components like scaffolding pins.

Innovations in alloy composition, surface treatment (galvanized, powder-coated), and quick-release mechanisms are shaping the future of scaffold toggle pins, with a strong focus on corrosion resistance and extended life cycles, particularly for petrochemical and marine construction.

2. Technical Specifications & Parameter Comparison

| Product Type | Material | Finish | Diameter | Length | Tensile Strength (Mpa) | Certification | Typical Application |

|---|---|---|---|---|---|---|---|

| Scaffolding Prop Pins | Q235 Steel / 45# Steel | Galvanized / Powder Coated | 10mm / 12mm / 14mm | 50mm-120mm | >450 | ISO 9001, ANSI/SSFI | Construction, Formwork |

| Scaffold Toggle Pins | Carbon Steel | Hot Dip Galvanized | 12mm | 65mm | >400 | EN 74, ISO 9001 | Refinery, Shipyard |

| Standard Scaffold Pins | SS316/304 | Electro Galvanized | 10mm-16mm | 50mm-130mm | >550 | ISO, ASTM | Marine, Water Supply |

Technical Trends of Scaffolding Pins (2019-2024)

Scaffolding Prop Pins vs. Conventional Pins: Durability Pie Chart

Mechanical Performance: Shear Strength Comparison

3. Manufacturing Process of Scaffolding Pins for Sale

The scaffolding pins for sale follow a rigorous ISO 9001-validated process, delivering unmatched consistency and strength. Let's visualize the stepwise production workflow for Scaffolding Prop Pins:

(High-grade Q235 / 45# Steel)

(CNC-controlled for Tolerance ≤0.03mm)

(High Pressure, Grain Refinement)

(Quenching for 20%+ Hardness Boost)

(Galvanizing/Coating for Anti-corrosion)

(Threading, Fine Cutting)

(ISO/ANSI Test Protocols)

(Batch Traceability)

▶ Watch the manufacturing video for scaffolding pins

- Inspection Standards: All products are batch-tested per ISO 9001:2015 & ANSI/SSFI SC100-5/05.

- Typical Surface Hardness: HRC 25-39 depending on pin type and application.

- Corrosion Cycle: Salt spray test ≥ 240 hours (ASTM B117), for marine and exterior applications.

4. Technical Advantages & Customization

- Superior Material Choice: Q235, 45# carbon steel, or 316 stainless steel provide high load capacity, low deformation, and long service life. Custom alloys available for petrochemical or anti-chloride environments.

- Advanced Coating: Hot-dip galvanizing ensures up to 5X higher corrosion resistance than painted pins.

- CNC-Precision Machining: Tighter dimensional tolerances minimize installation errors and enhance on-site safety.

- Load-Tested Performance: Guaranteed shear strength ≥ 14.8kN (for Φ12mm pin, as per ISO 2736:2016).

- Flexible Customization: Custom diameters (10–20mm), lengths (40–180mm), head types (plain, loop, T-bar), or even Company Logo laser-marking.

- Third-Party Testing: Each lot can be tested by SGS, TÜV, or Bureau Veritas for international clients.

5. Manufacturer Comparison & Certifications

| Brand/Supplier | Main Material | Certifications | Lead Time | Warranty | Major Clients |

|---|---|---|---|---|---|

| WRK Formwork | Q235/45# Steel, 316SS | ISO, ANSI, EN74 | 12-18 days | 24 months | CNOOC, SK E&C, Shougang |

| Plettac | High-tensile Steel | EN 12811, SSFI | 18-22 days | 12-18 months | BASF, Linde |

| Layher | Alloy Steel | ISO, JIS | 20-28 days | 18 months | Sinopec, Vinci |

| Cuplock China | Standard Carbon Steel | AS/NZS, ISO | 15-20 days | 12 months | Aramco, Technip |

Certifications ensure international acceptance, while reference clients validate real-world reliability.

WRK Formwork stands out for fast delivery, rich global references, and extended warranty support.

6. Customization Solutions for Scaffolding Pins

- Bespoke Dimensions: Supply us your project drawings, and we engineer made-to-order pins for your scaffolding system (Φ10–25mm, length 35–200mm possible).

- Integrated Design Support: Our in-house engineers (15+ years’ experience) help you design pin heads, slots, or locking rings to match multi-brand scaffolding.

- Logo & Color-Coding: Laser-engrave company trademarks, or apply unique powder-coat finishes for easy site ID and anti-theft.

- Testing & Traceability: Each custom batch supplied with full chemical, mechanical, and anti-corrosion reports (EN/ASTM/ISO standards).

- OEM/ODM Service: Non-standard head/locking designs for proprietary or patented scaffold solutions.

For a tailored quote, click here for scaffolding pins for sale support.

7. Application Scenarios & Best Use Cases

Case Study 1: Petrochemical Refinery, Middle East

- Project: Offshore oil platform maintenance

- Pin Type: 14mm hot-dip galvanized prop pins (ISO certified)

- Achieved: 0 lost time incidents in 9-month shutdown; salt spray testing exceeded 300 hours.

- Feedback: “Pin design enabled 30% faster scaffold erection” — Site Engineer, SK E&C

Case Study 2: Metallurgy Plant, Eastern Europe

- Project: Blast furnace overhaul, steel mill

- Pin Type: Customized 16mm stainless pins

- Achieved: No pin deformation after 750+ load cycles (EN 12810 tested)

- Feedback: “Withstood 24/7 high-temp and humidity exposure, flawless performance.”

Case Study 3: Water Treatment Construction, Southeast Asia

- Project: Large municipal pipeline installation

- Pin Type: Zinc-coated 12mm scaffold toggle pins

- Achieved: Pin corrosion after 12 months

- Feedback: “Pins were easy to assemble, saving costs and time on our urban sites.”

8. Client Feedback & Experience

“We switched to WRK’s scaffolding pins for sale on our blast furnace maintenance project. Not only did they pass ISO-specified destructive tests, but field crews reported zero jamming and rapid assembly, even in extreme weather. The 24-month warranty and technical support were key factors for us.” — Procurement Director, Steelmaker

9. Professional FAQ — Scaffolding Pins Terms Explained

A1: Most scaffolding pins for sale are manufactured from Q235 or 45# carbon steel for general construction. For anti-corrosion requirements or marine projects, SS316/304 stainless steel is also common. Material choice directly impacts load capacity, ductility, and corrosion performance.

A2: Leading products meet ISO 9001 for quality systems, ANSI/SSFI SC100-5/05 for scaffold safety, and sometimes EN 74 for European conformity. Certificates from SGS/TÜV may be provided for global projects.

A3: Typical diameters: 10mm, 12mm, 14mm; custom sizes from 8–20mm can be produced. Lengths range 40–180mm. Always confirm compatibility to ensure proper locking and alignment with your scaffold system.

A4: Pins undergo tensile/shear strength testing (≥14.8kN for Φ12mm as per ISO 2736), salt spray (ASTM B117), and repeated load cycling. Random ultrasonic inspection ensures internal flaw detection.

A5: Yes, we support third-party inspections by accredited agencies such as SGS, BV, TÜV at buyer’s request, with full dimensional and mechanical property protocols.

A6: Always insert pins fully through aligned holes, with locking rings or clips engaged per EN 12810/12811 standards. Improper or partial engagement reduces system integrity.

A7: Scaffolding pins for sale from WRK come with a standard 24-month warranty (material/workmanship), online technical support, and free replacements for any defect.

10. Delivery, Warranty & Customer Support

- Prompt Delivery: Standard batch (≤50,000 pcs) ships in 12-18 days. Custom pins: add 4–7 days for sampling.

- Quality Guarantee: 24-month warranty for normal application; free replacement for any defective pins.

- Traceable Production: All pins batch-coded for full traceability from raw material to delivery.

- After-sales Care: Comprehensive technical support, installation guidance, and rapid claim response (response .

11. Conclusion & Industry References

With rapid development in industrial safety standards and material technology, scaffolding pins for sale play an irreplaceable role in achieving cost-effective, safe, and long-lasting scaffolding systems. Industry-leading products like Scaffolding Prop Pins offer strong technical advantages, robust certification, rich real-world validation, and customizable support for special engineering needs.

By choosing a certified manufacturer, verifying technical data, and leveraging professional customer support, you safeguard your personnel and project investment on every site.

• "Scaffolding Connections: Structural Design & Safety," Forum: Scaffold Engineering World, 2024. https://scaffoldengineering.net/forums/safety-connections-best-practice

• "Corrosion and Fatigue Failures of Steel Scaffold Components," International Journal of Construction Materials, Vol. 41, No. 2, 2023. Read the full study

• "Specs & Lifecycle Data: Scaffolding Pins," Global Construction Network, 2024. https://www.globalconnet.com/scaffolding-pins-tech

• "EN12811/12810 Standard for Temporary Works," European Standards Organization. https://www.cen.eu/

Latest News

-

High-Quality Roofing Materials for Durable Building SolutionsNewsJul.30,2025

-

High-Quality Scaffold Coupling Pins for Secure ConnectionsNewsJul.29,2025

-

High-Quality Formwork Clamp for Concrete Construction, Durable & Easy to UseNewsJul.29,2025

-

High-Quality Prop Nut for Boats – Durable Propeller Nut with HandleNewsJul.29,2025

-

High-Quality Scaffolding Joint Pin for Secure ConnectionsNewsJul.28,2025