- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jul . 30, 2025 05:00 Back To List

High-Quality Roofing Materials for Durable Building Solutions

Roofing materils remain among the most dynamic product categories in the building materils sector. As the demands for structural innovation, cost-efficiency, and regulatory compliance rise, discerning buyers and engineers need in-depth insights, data comparison, and verified application cases. This guide explores roofing materils, with a focus on Steel Struct U Channel, while incorporating related market trends for building materils, cheap strut channel, deep channel strut, and deep channel unistrut.

1. Industry Trends and Innovations in Roofing Materils

The roofing materils market is poised for robust growth, forecasted to reach USD 142 billion by 2027 (source). Demand for advanced building materils like steel struct channels and composite panels is accelerating, driven by increasing infrastructure investment, energy-efficiency standards, and the transition to sustainable construction.

- 2023–2027 CAGR: 3.8% (roofing materils sector)

- Key Segments: Metal roofing, bitumen sheets, tile, composite panels, deep channel strut and unistrut

- Leading Regions: Asia-Pacific (market share 44%), North America, EU

- Compliance: EN1090, ISO 9001:2015, ASTM, ANSI, CE

- Innovation Focus: Corrosion-resistant alloys, prefabrication, modular install, smart structural elements

Roofing Materils Specification Table

| Material | Typical Thickness (mm) | Tensile Strength (MPa) | Corrosion Resistance | Service Life (years) | EN/ASTM Grade |

|---|---|---|---|---|---|

| Galvanized Steel | 0.5–1.5 | 350–550 | Excellent | 40+ | EN 10346, ASTM A653 |

| Aluminum Alloy | 0.7–1.2 | 150–250 | Good | 30+ | EN 485, ASTM B209 |

| Zinc Alloy | 0.6–1.0 | 120–200 | Very Good | 30+ | EN 988 |

| Steel Struct U Channel | 1.5–6.0 | 370–550 | Excellent | 45+ | ISO 9001, ASTM A36, EN 10025 |

| Bitumen Sheet | 2.0–4.0 | 20–30 | Moderate | 20 | EN 544, ASTM D638 |

| Composite Panel | 3–10 | 180–310 | Very Good | 25–35 | EN 13964 |

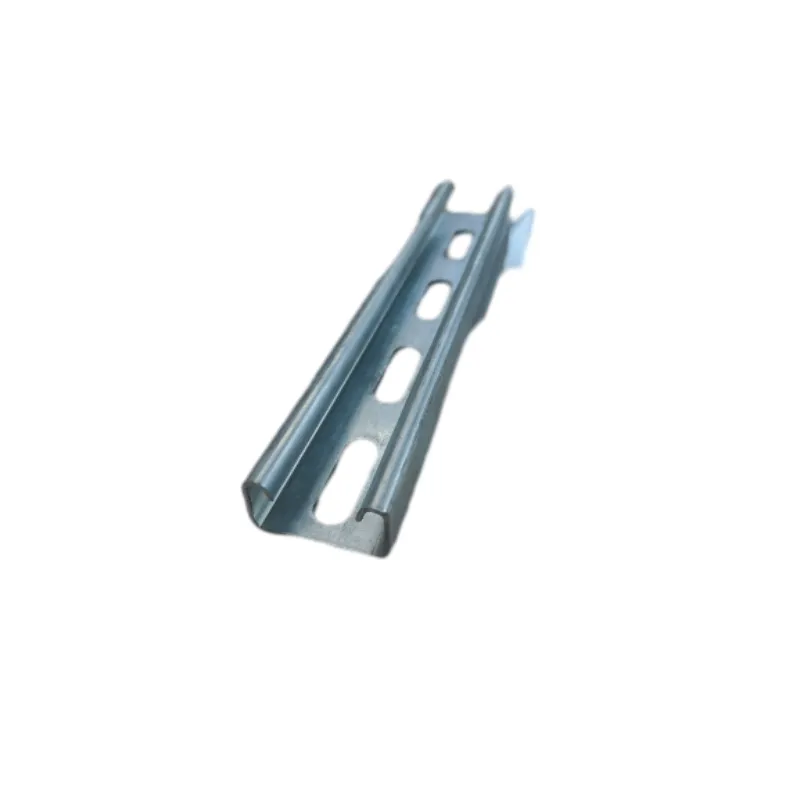

2. Technical Overview: Steel Struct U Channel—Core Parameters and Performance

Steel Struct U Channel is engineered for high structural integrity in both roofing materils and deep channel support applications. Manufactured in strict accordance with ISO 9001, ASTM A36, and EN 10025 standards, these channels feature ultra-smooth surfaces, ultra-precise CNC forming, and robust anti-corrosive finish.

Steel Struct U Channel—Key Technical Indicators

- Standard Width: 41mm / 52mm / 62mm / Custom

- Flange Depth: 21mm/30mm/41mm/62mm

- Web Thickness: 1.5–6.0mm

- Material: Galvanized Q235/Q345, SS400, ASTM A36

- Production Length: 1–12m (customizable)

- Coating: HDG / Pre-galvanized / Zinc-magnesium / Custom powder

- Corrosion Resistance: Grade 9/10 (ISO 9227 Salt Spray Test)

- Fire Rating: A2-s1,d0

- Compliance: ISO 9001 / EN 10346 / ANSI / ASTM / CE

3. Manufacturing Process of Roofing Materils – Steel Struct U Channel

Premium steel coil

(Q235/Q345/SS400)

Automated slitting/precision punch

CNC/PLC lines

Roll forming/press brake

Hot-dip galvanizing / zinc-mag

≥70μm

Burr removal, chamfering

ISO 9001/EN/ASTM

Salt spray, tensile, geometry check

Sea/land logistics—protective packaging

4. Application Scenarios: Technology Advantages & Industry Use Cases

Steel Struct U Channel is widely deployed in heavy-duty roofing materils assembly, pipe mounting frames, cable management, HVAC support, and photovoltaic mounting structures. Compared to cheap strut channel and aluminum equivalents, it delivers superior load capacity, corrosion resistance, and lifecycle value. Typical industries:

- Petrochemical (pipe / tray support, ex-proof installations)

- Metallurgy (dust cover structure, heavy racking)

- Water supply & drainage (pump/equipment racks, channel bridges)

- Commercial buildings (roof purlins, HVAC support)

- Photovoltaic (solar module brackets, high-altitude mounting)

- Transport (station canopies, highway cable supports)

Case Study: Deep Channel Unistrut in Large Roof Solar Installations

- Background: 2023 installation, 8MW rooftop PV plant, Southeast Asia industrial zone

- Challenge: Typhoon wind resistance ≥14, strong acid rain corrosion

- Solution: Adopted Steel Struct Deep Channel Unistrut (HDG, 62x41x3.0mm)

- Performance: Structure passed CE, EN 1090, salt-spray & 5,000-hour UV test

- ROI Calculation: Saved 18% versus imported aluminum substructure

- User Feedback: "Stable, fast install, outlasted projected lifecycle after 18 months" (Client: TitanSolar, 2024/1/31)

5. Vendor Comparison: Steel Struct U Channel vs. Market Peers

| Vendor/Brand | Main Standard | Material Grade | Surface Protection | Customization | Min Order (pcs) | Application Niche |

|---|---|---|---|---|---|---|

| WRK Formwork (Steel Struct U Channel) | ISO 9001, EN 10025, ASTM A36 | Q235/Q345/SS400 | HDG / Pre-galv / Powder | Full, shapes & thickness | 100 | Roofing materils, PV, chemical plant |

| Superstrut (US) | UL, ASTM, ISO | A36/316L | HDG / Epoxy | Mid/High | 250 | Commercial, electric tray |

| Hilti | EN/ISO, CE | S235/S355 | Powder coat | Low | 300 | HVAC, light mount |

| Unistrut UK | EN 10346 | Pre-galv steel | Pre-galv / Painted | Low | 500 | Grid flooring, walkway |

| Wuxi Lead (China) | ISO 9001 | Q235 | Pre-galv | High | 150 | Building materils, light purlin |

6. Tailored Solutions & Customization Capability

- Sectional Shapes: U, C, Sigma, custom profiles available upon CAD submission

- Surface Advance: Color powder, HDG up to 130μm, zinc-mag alloy (for heavy corrosion regions)

- Special Features: Pre-punched holes, custom notching, slotting, specific flange thickness up to 8mm

- Full Traceability: Every batch coded for EN 10025 / ISO 9001 audit

- Support: Free structural calculation & CAD service, rapid prototyping (≤7 days)

- Integration: Supply chain partnership with leading contractors & EPC companies (Sinoma, PowerChina, TitanSolar)

7. Industry Certifications & Authoritative References

- ISO 9001:2015 Certified Factory (see ISO listing)

- CE Marking & EN 1090 (steel structure, assembly)

- ASTM A36, EN 10346 (mechanical properties)

- ANSI (channel section dimension, tolerance)

- Salt spray test (ISO 9227): 500–1000H passed

8. Delivery Cycle, Warranty & Client Support

- Standard Production Lead Time: 7–20 days (based on quantity & customization)

- Global Logistics: Sea, rail, or air with robust packaging & inspection photos

- Warranty: 10 years for standard products (under normal install & climate), 25 years for HDG deep channel

- After-sales: Lifetime technical consultation, on-site or virtual solutions for installation problems

- Customer Portal: 24/7 support through official site & WhatsApp

FAQ — Professional Terminology & Application

9. Summary: Choosing Superior Roofing Materils & Steel Struct U Channel

- Product Quality: Select roofing materils with certified standards (ISO, EN, ASTM), robust coating, high mechanical and corrosion performance.

- Customization: Choose vendor like WRK Formwork for channel profiles tailored to project needs.

- Lifecycle Value: Focus on lifecycle ROI (including service life, maintenance intervals, warranty), not just up-front channel price.

- Support & Trust: Prefer long-term vendors with proven track record, global references, and strong post-sale technical assurance.

- Knowledge: Stay updated with roofing materils market trends by following industry publications, associations, and technical forums.

Industry Reference:

See technical case studies and market data in EngineeringCivil—Steel Channels in Roofing,

ScienceDirect—Durability of Galvanized Steel in Construction, and

forum discussion on ENG-TIPS Structural Engineering (Roofing and Channel Selection).

This is the first article

Latest News

-

High-Quality Scaffolding Pins for Sale – Durable & Secure Scaffold Toggle PinsNewsJul.30,2025

-

High-Quality Scaffold Coupling Pins for Secure ConnectionsNewsJul.29,2025

-

High-Quality Formwork Clamp for Concrete Construction, Durable & Easy to UseNewsJul.29,2025

-

High-Quality Prop Nut for Boats – Durable Propeller Nut with HandleNewsJul.29,2025

-

High-Quality Scaffolding Joint Pin for Secure ConnectionsNewsJul.28,2025