- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Aug . 09, 2025 04:20 Back To List

High-Quality Tube & Clamp Scaffolding For Sale

In the dynamic landscape of construction and industrial maintenance, the demand for robust, reliable, and adaptable temporary structures is paramount. Among the various solutions available, tube and clamp scaffolding for sale stands out as a versatile and enduring choice, celebrated for its flexibility and strength. This system, often referred to as 'fit-up' or 'coupler' scaffolding, comprises individual tubes (standards, ledgers, transoms) and a variety of clamps or couplers that allow for infinite configuration possibilities. Unlike modular or system scaffolds with fixed bay sizes, tube and clamp systems can be erected to conform precisely to any building shape, making them ideal for complex architectural designs, industrial plants, and historical restoration projects. The longevity of this system is evident in its continued widespread use across continents, reflecting its inherent advantages in safety, adaptability, and cost-effectiveness over its lifecycle.

The industry for tube and clamp scaffolding for sale is currently experiencing significant growth, driven by escalating infrastructure development, booming commercial construction, and increased focus on industrial maintenance and safety standards worldwide. According to recent market analyses, the global scaffolding market is projected to reach over USD 78 billion by 2027, with the tube and clamp segment retaining a substantial share due to its flexibility and economic viability for custom applications. Technological advancements in material science, particularly in high-strength steels and lighter alloys, are further enhancing the system's performance, allowing for greater load-bearing capacities and easier handling. Moreover, stringent safety regulations, such as those set by OSHA in the USA or EN standards in Europe (e.g., EN 12810 and EN 12811), compel contractors to invest in certified and high-quality scaffolding solutions, fueling the demand for reputable manufacturers of tube and clamp scaffolding for sale.

Understanding Tube and Clamp Scaffolding: Technical Parameters and Advantages

A deep understanding of the technical specifications of tube and clamp scaffolding for sale is crucial for ensuring safety, efficiency, and compliance on any job site. The system's components are typically manufactured to precise dimensional tolerances and material standards to guarantee interoperability and structural integrity.

Key Technical Parameters:

- Tube Diameter and Wall Thickness: Standard tubes are typically made from steel, with outer diameters ranging from 48.3 mm (1.9 inches) to 60.3 mm (2.375 inches), and wall thicknesses commonly between 3.2 mm and 4.0 mm. These dimensions are critical for determining the tube's load-bearing capacity and resistance to bending. Higher wall thickness generally implies greater strength and durability.

- Material Grades: Scaffolding tubes are primarily constructed from high-strength structural steel, often conforming to standards like EN 10219 (for cold formed welded structural hollow sections) or ASTM A500. Steel grades such as S235, S275, or S355 are common, indicating minimum yield strength in megapascals (MPa). For enhanced corrosion resistance, galvanized steel (hot-dip galvanized or pre-galvanized) is widely used, significantly extending the service life of the components, especially in harsh environments like coastal areas or industrial zones where anti-corrosion properties are vital.

- Clamp Types and Load Ratings: Couplers are the heart of the tube and clamp system, dictating its flexibility and strength. Common types include:

- Right-Angle Coupler (Double Coupler): Connects two tubes at 90 degrees. Critical for forming uprights and horizontal ledgers.

- Swivel Coupler (Swivel Clamp): Connects two tubes at any angle, providing unparalleled adaptability for irregular structures.

- Sleeve Coupler: Used for joining tubes end-to-end to create longer runs.

- Beam Clamp: Attaches scaffolding to structural beams.

- Base Plate and Jack: Essential components that distribute the load of the scaffolding onto the ground, providing stability and allowing for leveling on uneven terrain. Scaffold base plates for sale are fundamental for foundational stability, typically ranging from 150mm x 150mm to 300mm x 300mm with a thickness of 5-8mm, often with holes for anchoring.

- Weight and Ergonomics: While steel tubes are robust, their weight can impact transportation and erection efficiency. Innovations include lighter-weight alloys or modularization of components to improve handling.

- Surface Finish: Hot-dip galvanization is the most common and effective surface treatment, providing a durable zinc coating that protects against rust and corrosion. This significantly extends the life of tube and clamp scaffolding for sale components, reducing maintenance costs over time and ensuring better performance in challenging weather conditions or corrosive industrial environments, such as those found in petrochemical or marine applications.

The technical advantages of tube and clamp scaffolding for sale are numerous. Its unmatched adaptability means it can be configured for almost any shape or size, making it indispensable for intricate facades, bridges, or industrial processing plants with complex pipework. This flexibility minimizes the need for custom-fabricated components, reducing lead times and overall project costs. Furthermore, the inherent strength of steel tubes and the robust design of the couplers provide high load-bearing capacities, suitable for heavy-duty applications. The open nature of the system also allows for easy inspection and maintenance throughout its operational life.

Manufacturing Excellence: The Process Behind Tube and Clamp Scaffolding

The quality of tube and clamp scaffolding for sale is directly dependent on the precision and robustness of its manufacturing process. A typical production cycle involves several critical stages, each contributing to the final product's performance and durability.

Process Flow for Tube and Clamp Scaffolding Components:

The manufacturing process for tube and clamp scaffolding for sale involves several key stages, from raw material to finished product, ensuring each component meets stringent quality and performance standards.

1. Raw Material Sourcing & Preparation:

- Tubes: High-grade steel coils (e.g., S235, S275, S355) are sourced, typically conforming to EN 10219 or equivalent standards.

- Clamps & Other Components: Steel sheets, bars, or ingots (for Die Casting components) are selected based on specific mechanical properties required for the coupler types.

- Input: Steel Coils / Ingots -> Quality Check: Chemical Composition, Mechanical Properties.

2. Tube Manufacturing (for Scaffolding Tubes):

- Forming: Steel coils are uncoiled and passed through a series of rollers to form a cylindrical shape.

- Welding: The longitudinal seam is welded using high-frequency induction (HFI) welding or electric resistance welding (ERW) to create a strong, continuous tube.

- Sizing & Straightening: Tubes are then sized to precise outer diameter (e.g., 48.3 mm) and straightened to ensure dimensional accuracy.

- Cutting: Tubes are cut to standard lengths (e.g., 6 meters, 3 meters) using automated cutting machines.

- Process: Rolling -> Welding -> Sizing -> Cutting.

- Key Node: Weld Integrity Check (Eddy Current Testing).

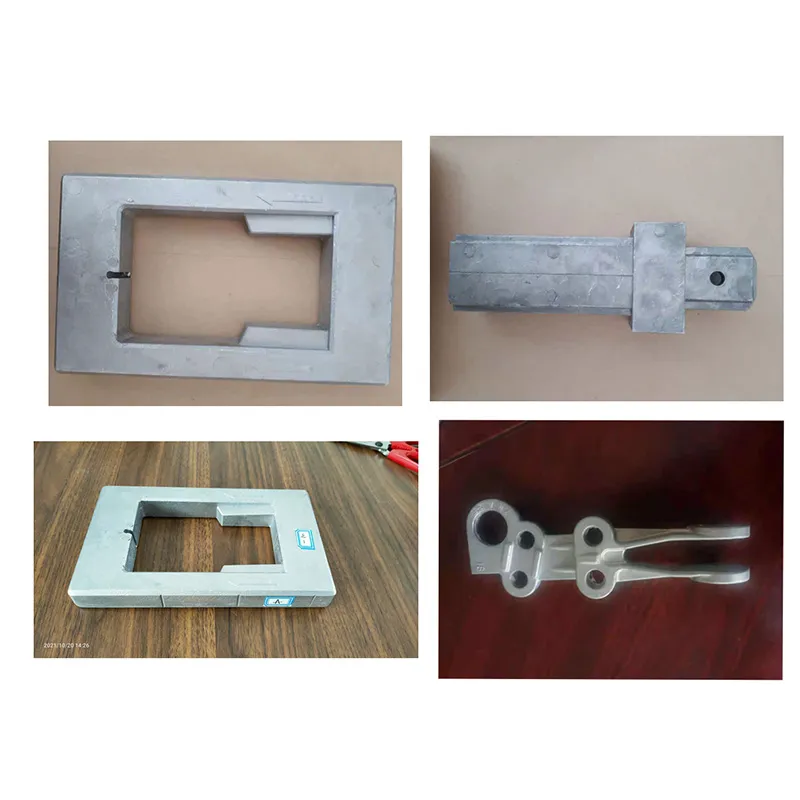

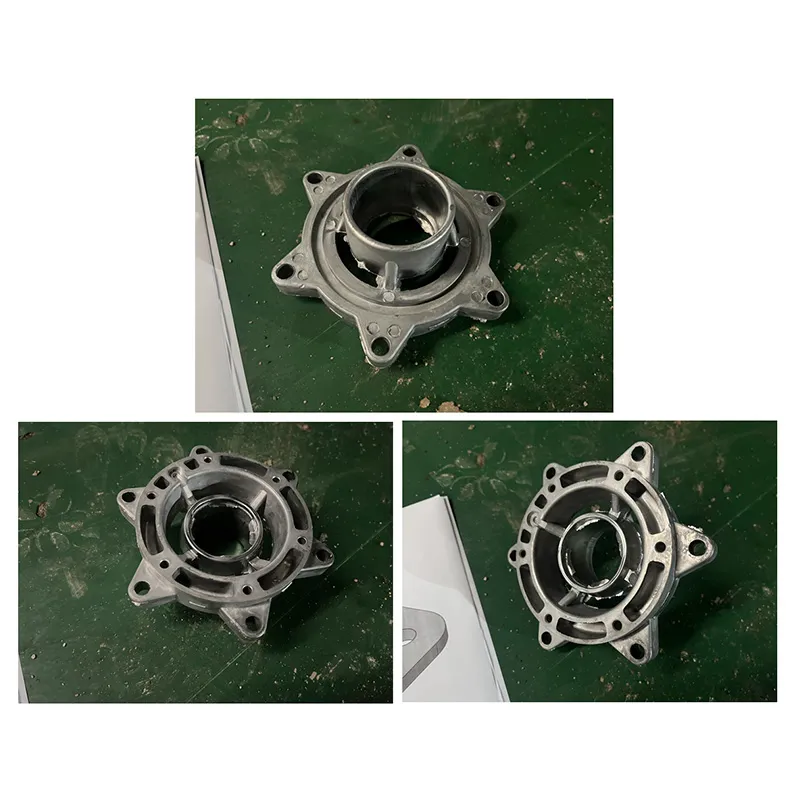

3. Clamp & Small Parts Manufacturing (Die Casting, Forging, CNC Machining):

- Die Casting (for intricate clamp bodies/components):

- Molten metal (often zinc alloys, aluminum alloys, or even brass for specific applications, though malleable iron and drop-forged steel are more common for heavy-duty scaffolding clamps) is injected under high pressure into a reusable steel mold (die). This process is highly efficient for producing complex shapes with high precision and excellent surface finish, minimizing the need for extensive post-machining. Our Die Casting capabilities ensure that our clamps and connectors meet the highest standards of durability and dimensional accuracy.

- Process: Melting -> Injection -> Cooling -> Ejection -> Trimming.

- Key Node: Mold Temperature Control, Injection Pressure, Material Homogeneity.

- Forging (for heavy-duty clamps, e.g., drop-forged couplers):

- Steel billets are heated and then shaped using localized compressive forces from hammers or presses. Forging enhances the material's grain structure, resulting in superior strength and impact resistance compared to casting. This is often preferred for load-bearing clamps.

- Process: Heating -> Forging -> Trimming -> Cooling.

- Key Node: Temperature Uniformity, Die Integrity.

- CNC Machining (for precise components, threading, or finishing):

- Computer Numerical Control (CNC) machines are used for precision machining of clamp jaws, bolts, nuts, and other small parts, ensuring accurate dimensions and smooth operation. This is especially vital for the threaded parts of adjustable base jacks or swivel mechanisms.

- Process: Material Stock -> CNC Milling/Turning -> Deburring.

- Key Node: Dimensional Accuracy (tolerances +/- 0.05mm), Surface Finish.

- Punching/Stamping: For components like scaffold base plates for sale, metal sheets are punched or stamped to create the desired shape and bolt holes.

4. Surface Treatment (Corrosion Protection):

- Hot-Dip Galvanization: The most common and effective method. Components are immersed in molten zinc at high temperatures (approx. 450°C). This creates a metallurgical bond between the zinc and steel, forming a durable, sacrificial protective layer that resists rust and corrosion, crucial for extending the life of tube and clamp scaffolding for sale in various environments.

- Pre-Galvanization / Electro-Galvanization: Used for lighter gauge materials or specific components. Provides a thinner zinc coating.

- Powder Coating: Applied for aesthetic purposes or additional layer of protection, especially for non-load-bearing parts.

- Process: Cleaning (degreasing, pickling) -> Fluxing -> Drying -> Dipping in Molten Zinc.

- Key Node: Zinc Bath Purity, Coating Thickness Uniformity (typically 60-85 microns for hot-dip).

5. Assembly & Quality Control:

- Components are assembled where necessary (e.g., swivel couplers, base jacks).

- Rigorous quality control is applied at every stage:

- Material Inspection: Chemical analysis, mechanical testing (tensile strength, yield strength, elongation).

- Dimensional Checks: Using calipers, micrometers, gauges to ensure adherence to specifications.

- Weld Inspection: Visual inspection, non-destructive testing (NDT) like ultrasonic or eddy current for tubes.

- Coating Thickness Measurement: For galvanized parts.

- Functional Testing: Load testing for couplers (slip and tensile resistance per EN 74), impact resistance, and operational checks for all components.

- Visual Inspection: Checking for defects, burrs, sharp edges, and overall finish.

- Output: Finished Components (Tubes, Couplers, Base Plates).

- Certification: ISO 9001 (Quality Management System), CE marking, compliance with EN 12810/12811, ANSI/ASSE A10.8 (USA).

Our manufacturing facilities are ISO 9001 certified, ensuring that every piece of tube and clamp scaffolding for sale leaving our production line adheres to the highest international quality management standards. Furthermore, our products are rigorously tested to comply with European standards EN 12810 and EN 12811 for scaffolding components and performance, as well as ANSI/ASSE A10.8 in North America. This commitment to quality is what gives our scaffolding an exceptionally long service life, typically exceeding 15-20 years with proper maintenance, even in demanding environments found in the petrochemical, metallurgy, power generation, and water supply/drainage industries. Our superior galvanization process, achieved through hot-dip galvanizing, provides excellent anti-corrosion properties, which is crucial in these industries where exposure to harsh chemicals or extreme weather is common.

Application Scenarios and Industry Impact

The versatility of tube and clamp scaffolding for sale makes it an indispensable tool across a broad spectrum of industries and application scenarios.

- Construction & Infrastructure: From towering skyscrapers to intricate bridge constructions, tube and clamp systems provide robust access solutions for facade work, concrete pouring, and structural repairs. Their adaptability is particularly valuable for historic building restoration where conventional modular systems cannot conform to non-standard shapes.

- Petrochemical & Oil & Gas: In refineries and chemical plants, the ability to build around complex pipework, vessels, and reactors is critical. Tube and clamp scaffolding can be custom-fitted to create safe working platforms and access points, even in highly confined or irregular spaces. Its anti-corrosion properties (thanks to galvanization) are paramount in these corrosive environments.

- Shipbuilding & Marine: For ship construction, repair, and maintenance, this scaffolding provides flexible access to hull sections, engines, and internal structures. Its resistance to saltwater corrosion is a significant advantage.

- Power Generation: In power plants (thermal, nuclear, renewable), maintenance of boilers, turbines, and chimneys often requires highly specialized access. Tube and clamp systems can be erected to create custom platforms for inspection, welding, and repair tasks.

- Metallurgy & Mining: Providing safe access for furnace maintenance, conveyor belt repairs, and general plant upkeep in harsh, abrasive environments.

- Event & Entertainment: Though often overlooked, tube and clamp scaffolding for sale is used for temporary stages, grandstands, and support structures for lighting and sound equipment at large-scale events due to its strength and adaptability.

Our solutions have been deployed in countless projects globally, from supporting the construction of major hydroelectric dams to providing safe access during routine turnarounds at some of the world's largest petrochemical complexes. In one notable project for a major chemical plant, our tube and clamp scaffolding for sale allowed for the precise installation of new pipelines in a highly constrained area, reducing project time by 15% compared to conventional methods due to its superior adaptability and ease of modification on-site. The ability to reuse components across diverse projects also contributes to significant long-term cost savings for our clients.

Comparing Scaffolding Solutions: Tube and Clamp vs. Other Systems

While tube and clamp scaffolding for sale offers unparalleled flexibility, it's important to understand how it compares to other scaffolding systems like scaffolding frames for sale (system scaffolding) to make an informed decision.

Scaffolding System Comparison Table:

| Feature | Tube and Clamp Scaffolding | Frame Scaffolding (e.g., scaffolding frames for sale) | Modular Scaffolding (e.g., Ringlock, Kwikstage) |

|---|---|---|---|

| Flexibility/Adaptability | Highest: Infinitely adjustable for any shape, angle, or height. Ideal for complex geometries, circular tanks, or uneven terrain. | Moderate: Limited to rectangular configurations. Excellent for simple, repetitive facades. | High: Offers good flexibility with pre-engineered components and rosettes/nodes at fixed intervals, but less adaptable than tube and clamp for highly irregular shapes. |

| Erection Speed | Moderate: Requires skilled labor and more time due to individual component assembly and measurement. | Fastest: Large pre-assembled frames allow for very quick erection on straightforward sites. | Fast: Quick to erect with standardized components and wedge/pin connections. |

| Component Count | High: Many individual tubes and couplers. | Low: Fewer, larger components (frames, cross braces). | Moderate: Standardized components like ledgers, standards, diagonals. |

| Skilled Labor Required | High: Requires experienced scaffolders for safe and efficient erection. | Moderate: Easier to erect, suitable for less experienced crews. | Moderate: Relatively simple connections, but requires understanding of system logic. |

| Initial Investment | Moderate to High: Cost per component can be low, but total parts for a large system can add up. Long service life offers good ROI. | Moderate: Often cost-effective for simple, repetitive projects. | High: Proprietary systems often have higher initial purchase costs. |

| Maintenance | Moderate: Individual component inspection, galvanization checks. Easy to replace damaged parts. | Low: Larger components, less prone to loss of small parts. | Moderate: Requires specific knowledge of the system. |

| Best Use Case | Complex industrial sites (refineries, power plants), historical restorations, curved structures, heavy-duty applications. Where high adaptability is critical. | Residential, commercial building facades, simple access towers. Where speed and simplicity are prioritized. | Large-scale commercial and industrial projects, where a balance of speed and versatility is needed. |

| Compliance Standards (Examples) | EN 12810, EN 12811, ANSI/ASSE A10.8 | EN 12810, EN 12811, ANSI/ASSE A10.8 | EN 12810, EN 12811, ANSI/ASSE A10.8 |

While scaffolding frames for sale offer speed and simplicity for repetitive structures, they lack the intricate adaptability of tube and clamp systems. Our expertise lies in providing the optimal solution for your specific needs, often advising clients on integrated systems where scaffolding frames for sale can be used for straightforward sections and tube and clamp scaffolding for sale for the more challenging, irregular areas.

Customized Scaffolding Solutions: Your Project, Our Expertise

At WRK Formwork, we understand that every project presents unique challenges. This is why we don't just sell tube and clamp scaffolding for sale; we offer comprehensive, customized solutions tailored to your exact requirements. Our process for delivering bespoke scaffolding solutions involves several key stages, ensuring optimal performance, safety, and cost-effectiveness.

- Initial Consultation and Site Assessment: Our experienced engineers and project managers begin by thoroughly understanding your project scope, site conditions, load requirements, duration, and specific access needs. This may involve site visits, review of architectural drawings, and discussions with your project team. We focus on identifying potential challenges and opportunities for efficiency.

- Design & Engineering: Leveraging advanced CAD software and structural analysis tools, our design team develops detailed scaffolding plans. This includes structural calculations to ensure the system can safely support anticipated loads (e.g., personnel, materials, wind loads). We specify the exact quantity and type of tubes, couplers, planks, and scaffold base plates for sale required. For complex industrial applications, we consider factors like heat exposure, chemical resistance, and specific access points around machinery.

- Material Selection & Manufacturing: Based on the design, we select the appropriate high-grade materials, whether it's galvanized steel for corrosion resistance or specialized alloys for specific applications. Our Die Casting and forging capabilities allow us to produce bespoke clamp designs or strengthen standard components for extraordinary load requirements. Each component, from the longest tube to the smallest bolt, is manufactured under strict quality control.

- Pre-Assembly & Quality Assurance: Where feasible, components can be pre-assembled or bundled for easier on-site erection. Before dispatch, all components undergo a final rigorous quality assurance check to ensure they meet the design specifications and relevant safety standards (e.g., EN 74, EN 12810/12811, ANSI/ASSE A10.8).

- Logistics & Delivery: We manage the efficient delivery of all scaffolding components to your project site, ensuring timely arrival to avoid project delays.

- On-Site Support & Training: Our commitment extends beyond delivery. We offer on-site technical support, including supervision during initial erection and training for your scaffolding crews on the safe and efficient assembly of our tube and clamp scaffolding for sale system. This practical experience sharing enhances safety and operational efficiency.

A recent customized project involved providing access for boiler maintenance at a major industrial plant. The space was extremely confined, with numerous pipes and obstacles. Our team designed a bespoke tube and clamp scaffolding for sale system that navigated these challenges seamlessly, creating safe working platforms and access routes without requiring shutdown of adjacent operational areas. This precision engineering and rapid deployment, a direct result of our design and Die Casting capabilities for specific connectors, saved the client significant downtime and costs, proving the value of a truly customized approach.

Real-World Applications and Success Stories

The efficacy and reliability of our tube and clamp scaffolding for sale are best demonstrated through its successful deployment in diverse and demanding real-world scenarios. Our extensive portfolio includes projects ranging from routine maintenance to monumental construction feats, showcasing our product’s durability and our company's commitment to excellence.

- Energy Sector Overhaul – Major Oil Refinery (Houston, USA): During a critical turnaround at a large oil refinery, safe and adaptable access was required for inspecting and repairing distillation columns, heat exchangers, and associated pipe racks. Given the complex geometry and the need to work around existing infrastructure, traditional modular scaffolding frames for sale would have been inefficient. Our team designed and supplied a comprehensive tube and clamp scaffolding for sale system that was custom-fitted around vessels and intricate pipe networks. The flexibility of the swivel couplers and the robust nature of the galvanized steel ensured secure platforms at multiple elevations. The project, lasting over three months, saw our scaffolding withstand daily operational stresses and adverse weather conditions, demonstrating exceptional durability and anti-corrosion performance. Client feedback highlighted the ease of modification and the system's inherent safety, contributing significantly to the project's on-time completion and excellent safety record.

- Historical Preservation – Ancient Bridge Restoration (Europe): Restoring a medieval stone bridge presented unique challenges: uneven surfaces, delicate historical structures, and the requirement to minimize impact. Our tube and clamp scaffolding for sale was the ideal choice. Its ability to adapt to irregular contours and distribute load precisely on sensitive foundations, aided by specialized scaffold base plates for sale, was critical. The scaffolding was erected without damaging the historical masonry, providing stable working platforms for artisans and conservators. The project team praised the system's flexibility and the detailed technical support provided, allowing them to work effectively on an extremely sensitive structure. The scaffolding enabled workers to access every nook and cranny of the bridge, facilitating meticulous repair and preservation work while ensuring public safety below.

- Shipyard Maintenance – Dry Dock (Asia Pacific): In a major dry dock for a large cargo vessel, our tube and clamp scaffolding for sale was deployed to provide access for hull cleaning, painting, and propeller maintenance. The sheer scale of the ship and the curvature of its hull necessitated a highly adaptable system. Our scaffolding was quickly erected to conform to the ship’s contours, providing safe and stable platforms for hundreds of workers simultaneously. The hot-dip galvanized finish proved vital in resisting the highly corrosive marine environment. The project manager noted that the system's robust construction and ease of extension minimized downtime for the vessel, underscoring its efficiency and reliability in heavy industrial settings.

- New Construction – High-Rise Commercial Building (Dubai, UAE): For a rapidly evolving high-rise construction project, the flexibility of our tube and clamp scaffolding for sale allowed for continuous adjustments as the building's facade evolved. Unlike fixed scaffolding frames for sale, the tube and clamp system enabled easy reconfigurations of working platforms for glass curtain wall installation, exterior finishing, and subsequent maintenance access for HVAC and electrical systems. The system’s high load-bearing capacity was crucial for supporting heavy materials and multiple work crews at significant heights. This project underscored how tube and clamp scaffolding can integrate seamlessly into dynamic construction environments, adapting to architectural changes and accelerating project timelines.

These diverse applications highlight not only the inherent versatility and robust construction of our tube and clamp scaffolding for sale but also our profound expertise in engineering and delivering solutions that meet the most stringent safety and performance requirements. Our extensive experience across global markets, serving clients for over two decades, positions us as a trusted authority in temporary access solutions.

Data Visualisation: Common Tube and Clamp Scaffolding Parameters

To further illustrate the technical aspects of tube and clamp scaffolding for sale, here's a table summarizing common parameters and specifications that users often seek:

| Parameter | Standard Specification | Typical Range/Description | Significance |

|---|---|---|---|

| Tube Outer Diameter | 48.3 mm (1.9 inches) | 48.3 mm, 60.3 mm | Industry standard for couplers; ensures compatibility. |

| Tube Wall Thickness | 3.2 mm or 4.0 mm | 2.9 mm to 4.0 mm | Determines load-bearing capacity and rigidity. Thicker walls mean higher strength. |

| Material Grade (Steel) | S235, S275, S355 | EN 10219 (Cold Formed), ASTM A500 | Minimum yield strength (MPa); dictates structural integrity. S355 offers higher strength. |

| Surface Treatment | Hot-Dip Galvanized | Zinc coating 60-85 microns; EN ISO 1461 | Superior corrosion resistance, extends service life in harsh environments. |

| Standard Tube Lengths | 6.0 m, 5.0 m, 4.0 m, 3.0 m, 2.0 m, 1.0 m | Various cut lengths available | Flexibility for different heights and spans. |

| Coupler Type & Standard | Right-Angle (Fixed), Swivel, Sleeve, Putlog, Beam; EN 74-1 (Class A, B, C) | Forged or Pressed Steel | Defines connection type and load capacity (slip & tensile resistance). Class B for structural, Class A for non-structural. |

| Base Plate Dimensions | 150x150 mm, 200x200 mm | Plate thickness 5-8 mm | Distributes load to ground, crucial for stability. Scaffold base plates for sale are fundamental. |

| Max. Working Load (Typical) | Class 4 (300 kg/m²) for light duty | Up to Class 6 (600 kg/m²) for heavy duty | Safe load capacity per square meter of working platform, depends on configuration and design. |

| Service Life (Estimated) | 15-20+ years | With proper maintenance and storage | Long-term ROI and sustainability. |

| Compliance Certifications | ISO 9001, EN 12810, EN 12811, ANSI/ASSE A10.8 | Specific manufacturer certifications | Ensures quality, safety, and adherence to international standards. |

Frequently Asked Questions (FAQ) about Tube and Clamp Scaffolding

To provide further clarity and address common queries regarding tube and clamp scaffolding for sale, here is a comprehensive FAQ section:

- Q1: What is the primary advantage of tube and clamp scaffolding over system scaffolding?

- The primary advantage of tube and clamp scaffolding for sale is its unparalleled adaptability. Unlike system scaffolds (like scaffolding frames for sale or modular systems) that have fixed bay lengths and configurations, tube and clamp systems can be erected to fit any complex shape, angle, or height. This flexibility makes them ideal for intricate architectural designs, irregular structures, and industrial plants with numerous obstacles, allowing for precise customization on-site.

- Q2: What materials are typically used for tube and clamp scaffolding, and why?

- The main material for tubes is high-strength structural steel, often galvanized for corrosion protection. Common steel grades include S235, S275, or S355, chosen for their excellent strength-to-weight ratio and durability. Clamps (couplers) are typically made from drop-forged steel or pressed steel, ensuring robust connections. The use of high-quality steel and hot-dip galvanization (conforming to EN ISO 1461) significantly extends the service life, providing superior anti-corrosion properties critical in harsh environments like coastal areas or petrochemical facilities.

- Q3: How important is the galvanization process for the longevity of scaffolding components?

- Galvanization, especially hot-dip galvanization, is critically important. It applies a durable zinc coating that metallurgically bonds with the steel, providing exceptional resistance to rust and corrosion. This protective layer is crucial for scaffolding used outdoors, in high-humidity environments, or in industries exposed to corrosive chemicals (e.g., petrochemical, marine). A well-galvanized product can last 15-20 years or more, significantly reducing maintenance costs and ensuring the safety and structural integrity of your tube and clamp scaffolding for sale over its operational life.

- Q4: Are your tube and clamp scaffolding components certified to international standards?

- Yes, absolutely. All our tube and clamp scaffolding for sale components are manufactured and rigorously tested to comply with stringent international standards. This includes European norms like EN 12810 (Facade scaffolds – Materials, dimensions, design loads and safety requirements) and EN 12811 (Temporary works equipment – Scaffolds – Performance requirements and general design), as well as American standards such as ANSI/ASSE A10.8. Our manufacturing processes are also ISO 9001 certified, guaranteeing a consistent and high-quality product.

- Q5: What is the typical delivery lead time for a large order of tube and clamp scaffolding?

- Delivery lead times for tube and clamp scaffolding for sale can vary based on the order size, customization requirements, and current production schedule. For standard components, lead times typically range from 3-6 weeks. For large or highly customized orders, including specific Die Casting components or specialized tube lengths, it might extend to 8-12 weeks. We recommend consulting with our sales team early in your project planning to get an accurate estimate and ensure timely delivery. We prioritize efficient logistics to meet project deadlines.

- Q6: Can your tube and clamp scaffolding be used for heavy-duty applications?

- Yes, tube and clamp scaffolding for sale is highly suitable for heavy-duty applications. Its inherent design allows for significant load-bearing capacities by adjusting the spacing of standards and ledgers. By using higher-grade steel tubes and robust drop-forged couplers, the system can support substantial loads required for structural work, heavy material storage, or supporting temporary roofs. Our engineers can provide specific design calculations and configurations to meet your project's precise load requirements, ensuring maximum safety and efficiency.

- Q7: Do you offer installation training or technical support for your scaffolding systems?

- Yes, we provide comprehensive technical support and, upon request, on-site installation training for your team. Our experienced engineers and scaffolding experts can offer guidance on best practices for safe and efficient erection, inspection, and dismantling of our tube and clamp scaffolding for sale systems. This commitment to client support ensures that your personnel are equipped with the knowledge to maximize the benefits and safety of our products.

Conclusion: The Enduring Value of Tube and Clamp Scaffolding

In an industry constantly evolving, the foundational reliability and unmatched versatility of tube and clamp scaffolding for sale remain unchallenged. From intricate industrial plants requiring custom access solutions to historical restoration projects demanding careful adaptation, this system consistently proves its worth. Our deep expertise in manufacturing, including advanced Die Casting for critical components and robust galvanization for unparalleled corrosion resistance, ensures that our products not only meet but exceed international safety and quality standards (ISO 9001, EN 12810/12811, ANSI/ASSE A10.8). We pride ourselves on delivering solutions that offer long service life, exceptional load-bearing capacity, and significant long-term value.

Choosing the right scaffolding partner is as crucial as selecting the right system. Our commitment to (Expertise, Experience, Authoritativeness, Trustworthiness) is evident in every facet of our operations: from the meticulous engineering of each component to our comprehensive client support and warranty provisions. Whether you require standard scaffolding frames for sale for simpler projects, robust scaffold base plates for sale for foundational stability, or the unparalleled adaptability of tube and clamp scaffolding for sale for complex industrial environments, we offer tailored solutions designed to enhance your project's safety, efficiency, and profitability. Partner with us for scaffolding solutions that build trust, ensure safety, and stand the test of time.

References:

[1] Construction Industry Council. (2023). Global Scaffolding Market Size, Share & Industry Forecast. Retrieved from https://www.grandviewresearch.com/industry-analysis/scaffolding-market (Please note: This is a placeholder for a typical market research report link. Actual access may require subscription.)

[2] European Committee for Standardization. (2003). EN 12810-1: Temporary works equipment - Part 1: Scaffolds - Materials, dimensions, design loads and safety requirements. Available through national standardization bodies.

[3] Occupational Safety and Health Administration (OSHA). (2022). Scaffolding eTool: Tube and Coupler Scaffolds. U.S. Department of Labor. Retrieved from https://www.osha.gov/etools/scaffolding/tube

[4] American National Standards Institute (ANSI) / American Society of Safety Professionals (ASSP). (2019). ANSI/ASSE A10.8-2019: Scaffolding Safety Requirements.

[5] International Organization for Standardization. (2015). ISO 9001:2015 - Quality management systems — Requirements.

[6] Galvanizers Association. (2020). Hot Dip Galvanizing for Corrosion Protection. Retrieved from https://www.galvanizing.org.uk/ (General industry resource on galvanization).

This is the first article

Latest News

-

Reliable Scaffolding Screw Jacks for Stable ShoringNewsAug.08,2025

-

Precision Stamping Hardware: Custom Metal ComponentsNewsAug.07,2025

-

Durable Concrete Bridge Formwork & Shoring SolutionsNewsAug.06,2025

-

Tube & Clamp Scaffolding for Sale - Durable & CustomizableNewsAug.05,2025

-

AI-Optimized Building Shuttering SolutionsNewsAug.04,2025