- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Aug . 08, 2025 04:40 Back To List

Reliable Scaffolding Screw Jacks for Stable Shoring

In the dynamic world of construction, efficiency, safety, and adaptability are paramount. At the heart of many robust temporary structures lies the unassuming yet critical component: screw jacks scaffolding. This comprehensive guide delves into the intricate details of these indispensable tools, exploring their industry trends, technical nuances, diverse applications, and the superior advantages they offer. We will also highlight the manufacturing excellence of our Scaffolding Pipe Couplers, which are integral to ensuring the stability and safety of these systems.

Understanding the Industry Landscape and Trends of Screw Jacks Scaffolding

The global scaffolding market, valued at approximately USD 60 billion in 2023, is projected to grow at a Compound Annual Growth Rate (CAGR) of over 5% from 2024 to 2032. This growth is primarily driven by rapid urbanization, increasing infrastructure development, and a heightened focus on construction safety standards. Within this expanding market, screw jacks scaffolding plays a foundational role, particularly in systems requiring precise height adjustment and load distribution.

Key trends influencing the adoption of screw jacks scaffolding include:

- Rising Demand for Modular Scaffolding: Modular systems, which heavily rely on adjustable components like screw jacks, offer quick assembly, disassembly, and adaptability, reducing labor costs and project timelines.

- Emphasis on Safety Regulations: Stricter global safety standards (e.g., OSHA, EN 12810) mandate the use of stable and precisely leveled scaffolding, making screw jacks indispensable for achieving compliance and preventing accidents.

- Innovation in Materials and Coatings: Advancements in high-strength steels and anti-corrosion coatings extend the lifespan and performance of screw jacks scaffolding, reducing maintenance and replacement costs.

- Digital Integration: The emergence of Building Information Modeling (BIM) and digital design tools allows for more accurate planning and deployment of scaffolding systems, optimizing the use of components like screw jacks.

The integration of technologies, coupled with the inherent versatility of screw jacks scaffolding, ensures its continued prominence in a wide array of construction, industrial, and maintenance projects worldwide.

Technical Parameters and Specifications of Screw Jacks Scaffolding

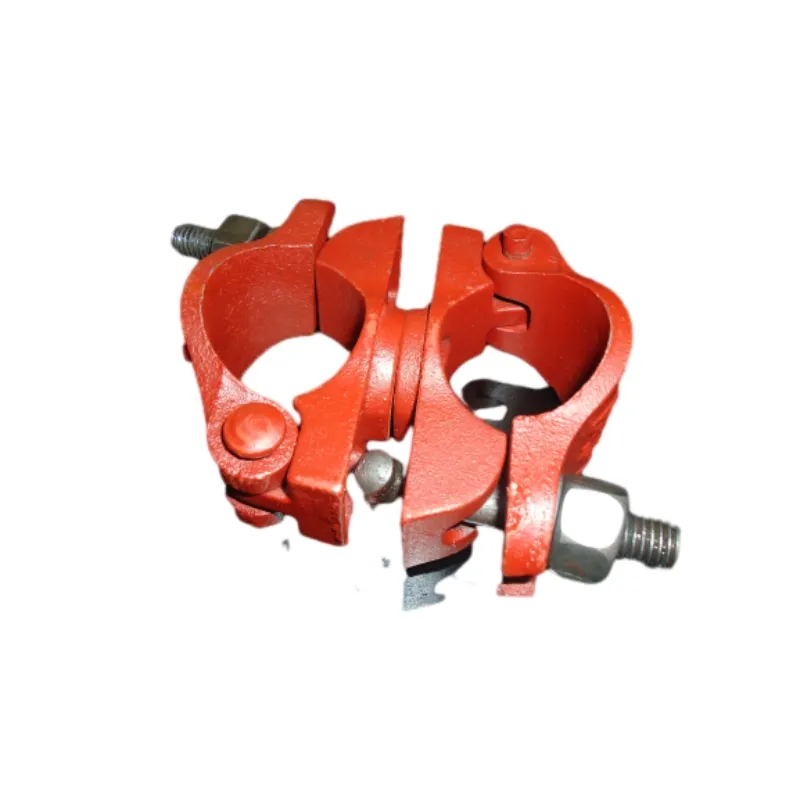

The effectiveness of screw jacks scaffolding hinges on its precise engineering and adherence to strict technical specifications. These components are designed to transfer vertical loads safely and efficiently from the scaffolding structure to the ground or supporting surface, accommodating uneven terrain and providing critical leveling capabilities. Our Scaffolding Pipe Couplers, such as the swivel coupler forged or shuttering pipe clamp, are crucial for securely joining these components.

Below is a table outlining typical technical parameters for screw jacks scaffolding components, offering insight into their capabilities and design considerations:

| Parameter | Description | Typical Range/Specification | Standard |

|---|---|---|---|

| Material Grade | High-strength carbon steel (e.g., Q235, Q345) for robustness and durability. | Carbon Steel (Q235, Q345, S235JR) | EN 10025, ASTM A36 |

| Surface Finish | Corrosion protection against environmental elements. | Hot-dip galvanized (HDG), Electro-galvanized, Powder Coated | ISO 1461 (HDG), ASTM B633 (EG) |

| Base Plate Size | Provides stable contact with the ground, distributing load. | 120x120 mm to 150x150 mm | Industry Standard |

| Base Plate Thickness | Ensures strength and prevents deformation under load. | 5 mm to 8 mm | Industry Standard |

| Adjustment Range (Threaded Length) | The total vertical distance that can be adjusted. | 150 mm to 750 mm (6 inches to 30 inches) | Varies by application |

| Outer Tube Diameter | Compatibility with standard scaffolding tubes. | 48.3 mm (OD) / 60.3 mm (OD) | EN 39, BS 1139 |

| Outer Tube Wall Thickness | Impacts load-bearing capacity. | 3.0 mm to 4.0 mm | EN 39, BS 1139 |

| Thread Type | Mechanism for smooth and precise adjustment. | Acme Thread, Trapezoidal Thread | ISO, ANSI B1.5 |

| Working Load Limit (WLL) | Maximum safe vertical load capacity. (Often dependent on full system) | 25 kN to 100 kN (5600 lbs to 22,000 lbs) per jack | EN 12810, AS/NZS 1576 |

| Ultimate Load (Safety Factor) | Minimum load at which failure occurs, typically 2.5-4 times WLL. | > 60 kN to > 300 kN | EN 12810, AS/NZS 1576 |

| Weight | Total weight of the screw jack assembly. | 3 kg to 15 kg (depending on size and type) | Manufacturer Specific |

These specifications are critical for engineers and site managers to select the appropriate screw jacks scaffolding for their specific project requirements, ensuring structural integrity and worker safety. The choice of material and surface finish, for instance, directly impacts the product's resistance to corrosion and its overall service life, especially in harsh environments. For instance, Hot-dip galvanized surfaces provide superior long-term corrosion protection compared to electro-galvanized, often specified for offshore or chemical plant applications.

Application Scenarios: Where Screw Jacks Scaffolding Excels

The versatility of screw jacks scaffolding makes it indispensable across a vast spectrum of industries and project types. Its ability to provide precise leveling and support makes it a cornerstone in various demanding environments.

- Construction & Building Demolition: From supporting formwork for concrete pouring to leveling the base of large-scale building scaffolds, screw jacks scaffolding ensures stability on uneven ground or sloped surfaces. For instance, in high-rise construction, they provide the initial level platform for the entire vertical structure.

- Infrastructure Projects: Bridges, tunnels, and highways often involve complex terrain. Shoring screw jacks are vital for temporary support structures, ensuring stability during excavation or concrete curing. They are also used in bridge deck construction to adjust the height of support beams.

- Industrial Maintenance (Petrochemical, Metallurgy, Power Plants): In these environments, workers often need to access elevated equipment for repair or inspection. Screw jacks scaffolding offers a reliable, adjustable, and safe platform, adaptable to the intricate layouts of industrial facilities. The anti-corrosive properties of galvanized jacks are particularly crucial in corrosive atmospheres found in chemical or petrochemical plants.

- Shipbuilding & Offshore: Providing stable working platforms around large vessels or offshore platforms where precision and robust support are non-negotiable. The inherent stability of screw jacks scaffolding is critical when dealing with the dynamic forces present in marine environments.

- Event Staging & Entertainment: For temporary stages, grandstands, or camera towers, precise leveling is essential for safety and visual appeal. Screw jacks provide quick and accurate adjustments for these temporary structures.

- Restoration & Renovation: Supporting delicate historic structures during restoration or providing stable access for facade work on existing buildings. Their adjustability allows them to adapt to existing architectural features without causing damage.

In all these applications, the ability of screw jacks scaffolding to precisely adjust height and distribute load evenly is paramount, contributing significantly to project safety, efficiency, and successful completion.

Technical Advantages of Robust Screw Jacks Scaffolding

The widespread adoption of screw jacks scaffolding is a testament to its compelling technical advantages, which translate directly into enhanced safety, efficiency, and cost-effectiveness on construction sites. These advantages are amplified when coupled with high-quality connecting elements like our Scaffolding Pipe Couplers (e.g., shuttering pipe clamp, swivel coupler forged).

1. Precise Leveling and Stability:

The most significant advantage of screw jacks scaffolding is its capability for fine-tuned height adjustment. This allows construction teams to create perfectly level and stable scaffolding structures even on highly uneven ground, slopes, or varying floor heights. This precision is critical for maintaining the structural integrity of the entire scaffold system and preventing lateral movement or collapse. Traditional fixed-height components cannot offer this level of adaptability.

2. Enhanced Safety and Compliance:

By ensuring a stable and level base, screw jacks scaffolding directly contributes to site safety. A well-leveled scaffold reduces the risk of tipping, swaying, or localized stress points that could lead to structural failure. Compliance with international safety standards such as EN 12810 (Scaffolds – Performance Requirements and General Design) and OSHA (Occupational Safety and Health Administration) regulations is significantly facilitated by the use of correctly installed and adjusted screw jacks.

3. Adaptability and Versatility:

Whether used as part of a traditional tube and fitting system or integrated into more advanced modular scaffolding, screw jacks scaffolding demonstrates immense adaptability. They are compatible with various scaffolding types (e.g., Ringlock, Cuplock, Kwikstage, or traditional tube-and-fitting systems), making them a universal component across different scaffold designs. This versatility reduces the need for specialized equipment, streamlining inventory and logistics.

4. Durability and Longevity (Corrosion Resistance):

Manufactured from high-grade steel and typically finished with hot-dip galvanization, screw jacks scaffolding boasts exceptional durability and resistance to corrosion. Hot-dip galvanization, conforming to ISO 1461 standards, provides a thick, robust zinc coating that protects the steel from rust, even in harsh outdoor environments, saline conditions (shipbuilding, offshore), or chemically aggressive industrial settings (petrochemical, chemical plants). This superior corrosion resistance extends the product's service life significantly, reducing replacement costs and maintenance downtime. A properly galvanized screw jack can last for decades, ensuring a strong return on investment.

5. Load Bearing Capacity:

Despite their adjustable nature, screw jacks scaffolding components are engineered to withstand significant vertical loads. Their robust design, utilizing high-tensile steel and precisely cut threads, ensures that they can safely support the weight of the scaffold structure, workers, materials, and tools. Each jack's Working Load Limit (WLL) is rigorously tested to ensure it meets or exceeds industry standards like those outlined in AS/NZS 1576 (Scaffolding – Design, Performance, and Testing).

6. Cost-Effectiveness:

While the initial investment in high-quality screw jacks scaffolding might seem higher than rudimentary alternatives, their long-term cost-effectiveness is undeniable. Their durability, reusability across multiple projects, reduced maintenance needs, and contribution to faster, safer project completion result in significant overall savings. Furthermore, preventing accidents through stable scaffolding drastically reduces potential legal liabilities and project delays.

In essence, investing in quality screw jacks scaffolding is an investment in the safety, efficiency, and profitability of any construction or industrial project. Their technical superiority makes them an indispensable element in modern scaffolding systems.

Detailed Manufacturing Process of Screw Jacks Scaffolding

The manufacturing of screw jacks scaffolding is a meticulous process that combines advanced engineering with robust material science to produce components that can withstand immense loads and harsh environments. Our production of Scaffolding Pipe Couplers and related components adheres to stringent quality controls, ensuring every product meets global performance and safety benchmarks. The typical process involves several key stages:

Step 1: Raw Material Selection & Inspection

Description: High-grade carbon steel (e.g., Q235, Q345, S235JR for tube; 45# steel for threaded rod) is selected based on specified mechanical properties and chemical composition. Materials undergo rigorous inspection (e.g., spectrometer analysis, tensile testing) to ensure compliance with standards like EN 10025 or ASTM A36. This foundational step is critical for the overall strength and durability of the finished screw jacks scaffolding.

Step 2: Tube Cutting & Forming

Description: Steel tubes are precisely cut to required lengths using automated sawing machines. The base plate and head plate (if applicable) are typically stamped or laser-cut from steel sheets. This ensures dimensional accuracy essential for proper fit and function within the scaffolding system.

Step 3: Thread Rolling/Machining

Description: For the threaded rod, either thread rolling or CNC machining is employed. Thread rolling involves cold forming the threads onto the rod, enhancing its strength and surface finish by maintaining the grain flow of the metal. CNC machining is used for higher precision and complex thread profiles. The nut (collar) is typically cast or forged and then precisely tapped with matching threads. This precise threading is paramount for the smooth, controlled adjustment of the screw jacks scaffolding and its load-bearing capability.

Step 4: Welding & Assembly

Description: Components (base plate to outer tube, threaded rod to head plate, and nut to inner tube collar if it's a fixed nut type) are precisely welded together. Advanced robotic welding or skilled manual arc welding techniques are used to ensure strong, clean, and consistent welds that can withstand heavy loads. Critical welds undergo non-destructive testing (NDT) like ultrasonic testing or magnetic particle inspection to detect any defects, ensuring the integrity of the screw jacks scaffolding.

Step 5: Surface Treatment (Hot-Dip Galvanization)

Description: After assembly, the entire component undergoes hot-dip galvanization, a superior anti-corrosion process. Components are thoroughly cleaned (degreasing, pickling) to remove impurities, then dipped into molten zinc at approximately 450°C. This creates a metallurgical bond between the steel and zinc, forming a highly durable, multi-layered protective coating. This process adheres to ISO 1461 standards, ensuring exceptional protection against rust, abrasion, and harsh environmental conditions, extending the service life of the screw jacks scaffolding significantly.

Step 6: Quality Control & Testing

Description: Each batch of finished screw jacks scaffolding undergoes rigorous quality control. This includes visual inspection for defects, dimensional checks, thread gauge testing, and performance testing. Load testing (both Working Load Limit (WLL) and Ultimate Load testing) is performed on representative samples to verify their load-bearing capacity and safety factor, conforming to standards like EN 12810 and ANSI/ASSE A10.8 (Scaffolding Safety Requirements). This ensures every piece of screw jacks scaffolding is fit for purpose and guarantees reliability.

Step 7: Packaging & Dispatch

Description: Finally, the tested screw jacks scaffolding components are carefully packaged to prevent damage during transit, typically in bundles or crates, and prepared for dispatch to construction sites globally. Proper packaging ensures the product arrives in optimal condition, ready for immediate use.

Our commitment to these detailed manufacturing steps and strict quality control measures ensures that our products, including our robust Scaffolding Pipe Couplers, deliver exceptional performance, reliability, and extended service life in even the most demanding applications, contributing to energy savings by reducing the need for frequent replacements due to corrosion or wear.

Manufacturer Comparison: Choosing the Right Partner for Screw Jacks Scaffolding

Selecting the right manufacturer for screw jacks scaffolding is a critical decision that impacts project safety, efficiency, and long-term costs. While many suppliers exist, discerning quality requires a keen eye for detail beyond just price. Here's a comparative framework to consider, highlighting what differentiates a reliable partner:

| Feature | Standard Manufacturer (Average) | Premium Manufacturer (e.g., WRK Formwork) |

|---|---|---|

| Material Quality | Often uses lower-grade, untested steel; inconsistent material sourcing. | High-grade, certified carbon steel (Q235, Q345, S235JR) with strict incoming material inspection and traceability (e.g., Mill Certificates compliant with EN 10204 3.1). |

| Manufacturing Process | Basic welding, manual threading, minimal automation; prone to inconsistencies and weaker joints. | Advanced robotic welding, precision CNC machining or cold-rolled threading for superior strength and smooth operation. High degree of automation for consistency. |

| Surface Finish & Corrosion Protection | Electro-galvanized (thin coating) or painted, offering limited corrosion resistance and shorter lifespan, especially in harsh environments. | Hot-dip galvanized (HDG) to ISO 1461 standards, providing a thick, durable, and self-healing zinc coating for extended lifespan and excellent corrosion resistance in all environments (e.g., salt spray tested to ASTM B117 for 1000+ hours). |

| Testing & Certification | Basic in-house checks; limited or no third-party certification. May not meet international standards. | Rigorous in-house QA/QC (e.g., 100% visual inspection, dimensional checks). Regular third-party testing (e.g., SGS, TUV) and full compliance with international standards (EN 12810, BS 1139, AS/NZS 1576, ANSI/ASSE A10.8). Provides test reports. |

| Load Bearing Capacity | May claim high capacities without robust testing or consistent manufacturing, leading to potential failure. | Clearly stated Working Load Limits (WLL) and Ultimate Load capacities, backed by extensive destructive and non-destructive testing (NDT) with safety factors typically ≥ 2.5:1 or 3:1. |

| Service Life | Shortened lifespan due to poor materials/coatings, requiring frequent replacement. | Extended service life (15-20+ years in typical conditions) due to superior materials, manufacturing, and corrosion protection, ensuring lower total cost of ownership. |

| Customization Capabilities | Limited to standard sizes; unable to meet specific project demands. | Offers bespoke design and manufacturing for unique project requirements, including custom lengths, base plate designs, and thread types. Engineering support available. |

| After-Sales Support & Warranty | Minimal or no warranty; difficult to get support for issues. | Comprehensive warranty (e.g., 5-10 years on manufacturing defects), dedicated customer support, and technical assistance for installation and maintenance. |

| Environmental & Social Responsibility | Often overlooks sustainable practices and worker welfare. | Adheres to environmental regulations (e.g., ISO 14001) and social responsibility (e.g., SA8000), including waste management, energy efficiency, and fair labor practices. |

At WRK Formwork, we pride ourselves on falling squarely into the "Premium Manufacturer" category for our screw jacks scaffolding and related products like Scaffolding Pipe Couplers. Our commitment to ISO 9001:2015 quality management systems, extensive R&D, and a service history spanning over a decade speaks to our authority and trustworthiness in the industry. We understand that quality components are not just products; they are critical investments in safety and project success.

Customization Solutions for Screw Jacks Scaffolding

Every construction project is unique, often presenting specific challenges that standard components may not fully address. Recognizing this, leading manufacturers of screw jacks scaffolding offer robust customization solutions, ensuring that scaffolding systems can be perfectly tailored to meet specific site requirements and engineering demands. This flexibility is a significant advantage, allowing for optimal performance and safety.

Customization options typically include:

- Length and Adjustment Range: While standard lengths are common, projects may require extra-long or unusually short screw jacks scaffolding to accommodate extreme terrain variations or specific structural elevations. Custom threading lengths allow for greater or finer adjustment capabilities.

- Base Plate and Head Plate Design:

- Base Plates: Can be customized in terms of size (e.g., larger square or round plates for increased load distribution on soft ground), thickness, or even with specialized anchoring holes for specific bracing requirements.

- U-Head Jacks (Fork Head Jacks): Essential for supporting timber beams or steel joists. Custom U-head dimensions (width, depth) can be manufactured to perfectly cradle specific beam sizes, ensuring a secure fit and optimal load transfer for shoring screw jacks applications.

- Material Grade and Coatings: For highly corrosive environments (e.g., chemical plants, offshore platforms) or projects requiring extreme load capacities, specialized steel alloys (e.g., high-tensile steel) or enhanced coating systems (e.g., duplex coatings combining galvanization with a paint layer) can be provided beyond standard hot-dip galvanization.

- Thread Type and Pitch: While Acme or Trapezoidal threads are standard, specific projects might benefit from a finer or coarser thread pitch for ultra-precise adjustments or faster height changes, respectively.

- Load Capacity Enhancements: For applications demanding higher Working Load Limits (WLL), screw jacks can be engineered with thicker walls, larger diameters, or reinforced internal structures to meet elevated safety factor requirements.

- Integration with Specific Scaffolding Systems: Ensuring seamless compatibility with unique or proprietary scaffolding systems, including customized connection points or collar designs, is a common customization request. This is where specialized Scaffolding Pipe Couplers become invaluable.

Our engineering team works closely with clients to understand their precise project needs, utilizing advanced CAD/CAM software to design and simulate custom screw jacks scaffolding solutions. This collaborative approach ensures that the final product not only meets but exceeds performance expectations, optimizing both safety and project efficiency.

Application Cases: Screw Jacks Scaffolding in Action

The practical utility and reliability of screw jacks scaffolding are best demonstrated through real-world applications. Here are a few illustrative case studies, showcasing their critical role in diverse construction and industrial scenarios:

Case Study 1: High-Rise Building Construction – Foundation Leveling

Project: Construction of a 50-story residential tower on a sloped urban site. Challenge: Establishing a perfectly level base for the main access and working scaffolds on an uneven, excavated foundation. Solution: Over 1,500 units of heavy-duty screw jacks scaffolding (60mm OD, 750mm adjustment range) with large base plates were deployed. These were integrated with a Ringlock scaffolding system. The screw jacks allowed site engineers to precisely level the entire scaffold footprint, compensating for a 2-meter elevation difference across the site. Outcome: Achieved a perfectly stable and level scaffolding base within 0.5% tolerance, ensuring the safety of workers and the efficient vertical progression of the building. The adjustability of the jacks reduced the need for extensive ground preparation, saving significant time and excavation costs.

Case Study 2: Bridge Deck Shoring – Infrastructure Development

Project: Casting of a new concrete deck for a highway bridge spanning a river. Challenge: Supporting massive concrete loads (up to 120 tons per pour section) at varying heights across the bridge's arch, requiring exact elevation control for formwork. Solution: A robust shoring screw jacks system, specifically U-head jacks with a WLL of 60kN each, were used in conjunction with steel shoring props. The precise threading on the U-head jacks enabled minute adjustments of the formwork height, ensuring the exact curvature and slope of the bridge deck. Outcome: The bridge deck was poured with exceptional dimensional accuracy, meeting stringent engineering specifications. The high load capacity and precise adjustment of the shoring screw jacks significantly enhanced the structural integrity during concrete curing, preventing costly rework.

Case Study 3: Petrochemical Plant Turnaround – Maintenance Access

Project: Routine maintenance and inspection of a refinery distillation column. Challenge: Providing safe and stable access platforms around complex piping and equipment at various elevations within a corrosive, confined environment. Solution: Lightweight yet robust screw jacks scaffolding with hot-dip galvanized finish (conforming to ISO 1461) was deployed. Their anti-corrosion properties were critical in the sulfur and chemical-rich atmosphere. The adjustable nature of the jacks, combined with shuttering pipe clamp and swivel coupler forged to connect to existing structures, allowed for rapid assembly and customization of access points. Outcome: Workers gained safe and flexible access to all necessary areas for inspection and repair. The anti-corrosion features of the galvanized jacks ensured their integrity throughout the shutdown, reducing potential equipment failure due to rust and minimizing the need for replacement components during future turnarounds, thus contributing to long-term cost savings and operational efficiency.

These cases underscore the indispensable value of high-quality screw jacks scaffolding in facilitating complex projects, ensuring safety, and optimizing operational timelines.

Building Trust: Our Commitment and Services

At WRK Formwork, trustworthiness is at the core of our operations. We understand that our products are fundamental to the safety and success of your projects. Our commitment goes beyond manufacturing high-quality screw jacks scaffolding and Scaffolding Pipe Couplers; it encompasses comprehensive support and transparency.

Certifications and Authority:

- ISO 9001:2015 Certified: Our entire manufacturing process, from raw material sourcing to final inspection, adheres to the most stringent international quality management standards.

- Compliance with Global Standards: Our products consistently meet or exceed international safety and performance standards including EN 12810, BS 1139, AS/NZS 1576, and ANSI/ASSE A10.8. We provide full test reports and material certificates upon request.

- Decades of Experience: With over 15 years in the scaffolding and formwork industry, we have a proven track record of delivering reliable solutions to projects of all scales worldwide. Our extensive experience grants us unparalleled expertise.

- Trusted Partnerships: We have established long-term relationships with leading construction companies and equipment rental firms globally, built on a foundation of consistent quality and reliable service.

Delivery and Logistics:

We understand the critical nature of timely deliveries in construction. Our robust supply chain and logistics network ensure efficient dispatch and delivery of your screw jacks scaffolding orders. Typical delivery cycles range from 2-4 weeks for standard products, with express options available for urgent requirements. We provide real-time tracking and dedicated logistics support to keep you informed every step of the way.

Quality Assurance and Warranty:

Every piece of screw jacks scaffolding and every Scaffolding Pipe Coupler undergoes rigorous multi-stage quality control. We stand behind our products with a comprehensive 5-year warranty against manufacturing defects, underscoring our confidence in their durability and performance. Our commitment to quality significantly reduces the total cost of ownership for our clients.

Customer Support and Technical Assistance:

Our dedicated customer support team is available to assist you with product selection, technical specifications, and after-sales service. We offer expert technical guidance for the optimal installation and maintenance of your screw jacks scaffolding to ensure maximum lifespan and operational safety. Our goal is to be a partner in your success.

Professional FAQ: Deep Dive into Screw Jacks Scaffolding

Here are answers to some frequently asked questions, providing deeper insights into the technical aspects and practical considerations of screw jacks scaffolding:

A hot-dip galvanized screw jacks scaffolding component, conforming to ISO 1461, typically has a lifespan exceeding 15 to 20 years in most atmospheric conditions. In highly corrosive industrial or marine environments, its life will still be significantly longer (e.g., 5-10 years) compared to painted or electro-galvanized alternatives, due to the superior barrier and sacrificial protection offered by the thick zinc coating. Regular inspection and proper storage can further extend this life.

While both are adjustable, a standard base screw jack is primarily used at the bottom of a scaffold to level the structure on the ground. A shoring screw jack (often a U-head jack or fork head jack) is specifically designed to be placed at the top of a vertical prop or within a shoring system. It features a U-shaped head that cradles and supports horizontal members like timber beams, steel joists, or formwork, providing precise height adjustment for heavy vertical loads in concrete pouring or structural support applications.

The thread type is crucial for both ease of adjustment and load-bearing capacity. Acme and Trapezoidal threads are preferred over standard V-threads because they have a wider profile and larger contact area, allowing them to support heavier axial loads without deforming or stripping. They also provide smoother and more precise adjustment under load, making them ideal for the continuous and fine-tuning required in screw jacks scaffolding for leveling and shoring.

Yes, screw jacks scaffolding are highly versatile. While the base plate and outer tube diameter must be compatible with the specific scaffold's vertical standards (e.g., 48.3mm OD for most modular systems or tube and fitting), the basic principle of height adjustment remains universal. Manufacturers offer different top-fitting designs (e.g., solid stem, hollow stem, U-head) to integrate seamlessly with various system types, often utilizing standard Scaffolding Pipe Couplers like a shuttering pipe clamp for secure connections.

Industry standards for screw jacks scaffolding typically mandate a minimum safety factor of 2.5:1 or 3:1 (Ultimate Load to Working Load Limit). This means the jack must be able to withstand at least 2.5 to 3 times its stated maximum working load before failure. This robust safety margin is critical for preventing catastrophic failures on construction sites, especially when dealing with dynamic loads or unexpected stresses.

While highly durable, regular maintenance extends the lifespan of screw jacks scaffolding. This includes routine cleaning to remove concrete, dirt, and debris, especially from the threads. Lubrication of the threads with a suitable grease (e.g., lithium grease) is recommended periodically to ensure smooth operation and prevent seizing. Visual inspections for signs of damage, wear, or corrosion (even on galvanized surfaces) should be conducted before and after each use.

Authenticity and quality are paramount. For products like swivel coupler forged or shuttering pipe clamp, we rely on certified raw materials (e.g., traceable steel billets), advanced manufacturing processes (like hot forging which enhances strength), and strict quality control. This includes material composition analysis, dimensional checks, proof load testing (for couplers), and slip resistance testing. Third-party certifications (e.g., CE, TUV, SGS) on our manufacturing processes and product batches provide independent verification of our adherence to international standards and ensure the reliability of our Scaffolding Pipe Couplers.

Conclusion: The Indispensable Backbone of Modern Construction

The evolution of construction and industrial practices consistently underscores the vital role of foundational components. Screw jacks scaffolding, far from being a mere accessory, stands as an indispensable backbone of modern temporary support structures. Its unparalleled ability to provide precise leveling, robust load support, and exceptional adaptability on diverse terrains makes it a critical element for ensuring safety, efficiency, and structural integrity across countless projects. From towering skyscrapers to intricate industrial plant maintenance, the strategic deployment of high-quality screw jacks scaffolding significantly reduces risks, streamlines operations, and contributes to the economic viability of construction endeavors.

Our commitment at WRK Formwork extends to manufacturing not just components, but solutions that empower safer and more efficient construction. By adhering to the highest standards in material selection, manufacturing processes (including precision hot-dip galvanization for enhanced longevity and corrosion resistance), and rigorous quality control, we ensure our screw jacks scaffolding and complementary Scaffolding Pipe Couplers (such as shoring screw jacks, shuttering pipe clamp, and swivel coupler forged) consistently exceed industry benchmarks. Investing in our products means investing in tested reliability, long-term durability, and the peace of mind that comes from using equipment designed for the most demanding conditions.

As the construction landscape continues to evolve, the demand for robust, adaptable, and meticulously engineered scaffolding components will only grow. Screw jacks scaffolding will remain at the forefront, underpinning the stability and success of future projects worldwide, proving its indispensable value time and again.

For further insights into scaffolding best practices and industry advancements, we recommend exploring resources from:

- Scaffolding Association (UK): https://scaffolding-association.org/

- OSHA (Occupational Safety and Health Administration) Scaffolding eTool: https://www.osha.gov/etools/scaffolding

- Journal of Construction Engineering and Management (ASCE): https://ascelibrary.org/journal/jcemtq

Latest News

-

Precision Stamping Hardware: Custom Metal ComponentsNewsAug.07,2025

-

Durable Concrete Bridge Formwork & Shoring SolutionsNewsAug.06,2025

-

Tube & Clamp Scaffolding for Sale - Durable & CustomizableNewsAug.05,2025

-

AI-Optimized Building Shuttering SolutionsNewsAug.04,2025

-

Formwork for In Situ Concrete | AI-Optimized SolutionsNewsAug.02,2025