- Phone: +86 132 8320 1810

- Email: annie@wrkgroup.ltd

-

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Indonesian

- Italian

- Japanese

- Javanese

- Malay

- Persian

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Telugu

- Vietnamese

Jul . 22, 2025 05:01 Back To List

Premium Building Materials for Durable Roofing & Ceilings

Revolutionizing Construction with Advanced Building Materials

The construction industry is undergoing a profound transformation driven by technological advancements in building materials. Modern construction demands materials that offer superior strength-to-weight ratios, sustainability, and ease of installation. The evolution of roofing materials and framing systems has dramatically reshaped architectural possibilities while enhancing structural integrity.

Leading this transformation are advanced metal systems including light steel keel frameworks, galvanized metal ceiling solutions, and pro rib steel ceiling configurations. These materials represent a quantum leap from traditional construction approaches, offering design flexibility without compromising structural integrity. According to the International Journal of Advanced Structural Engineering, modern metal framing systems can reduce construction time by up to 40% while improving thermal efficiency by 30% compared to conventional methods.

At CANGZHOU WORLD CUP TRADING CO.,LTD., we specialize in manufacturing premium construction components that meet these evolving industry standards. Our flagship product - the Light Steel Keel - exemplifies the cutting-edge innovation shaping today's building materials landscape. This versatile framing solution offers architects and builders unprecedented design flexibility without compromising structural integrity.

Technical Specifications of Modern Building Materials

| Material Type | Tensile Strength (MPa) | Weight (kg/m²) | Corrosion Resistance | Thermal Conductivity (W/m·K) | Typical Applications |

|---|---|---|---|---|---|

| Light Steel Keel | 340-550 | 0.6-1.2 | High (Galvanized coating) | 50-60 | Partition walls, ceiling systems |

| Galvanized Metal Ceiling | 280-450 | 1.5-3.5 | Excellent (Zinc coating) | 45-55 | Commercial interiors, clean rooms |

| Pro Rib Steel Ceiling | 380-520 | 2.8-4.2 | Exceptional (Galfan coating) | 40-50 | Industrial facilities, warehouses |

| Advanced Roofing Materials | 300-500 | 3.0-5.5 | High (PVDF coating) | 35-45 | Commercial roofing, institutional buildings |

Light Steel Keel: The Future of Structural Framing

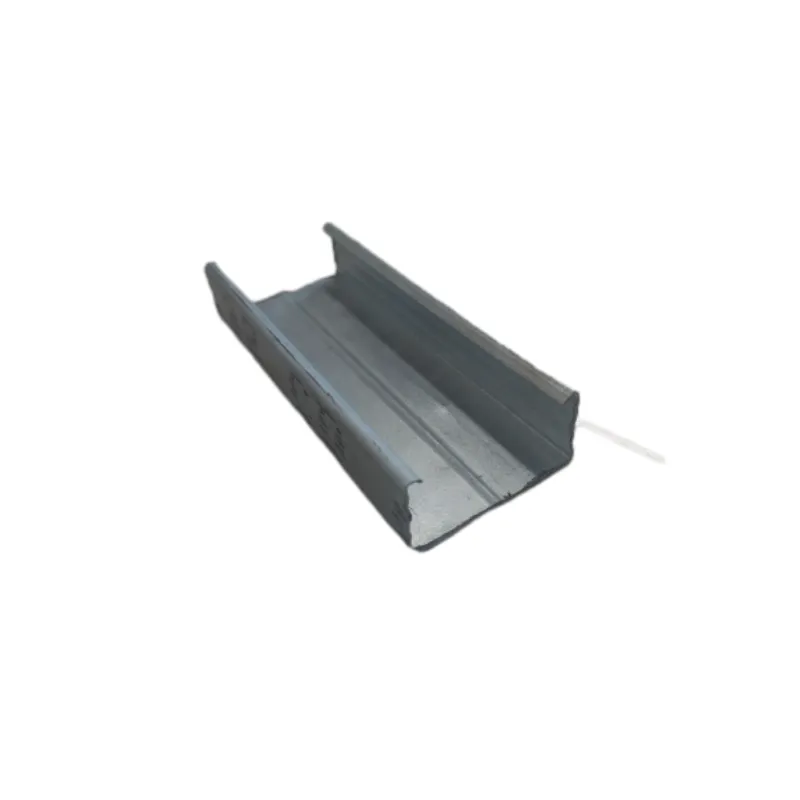

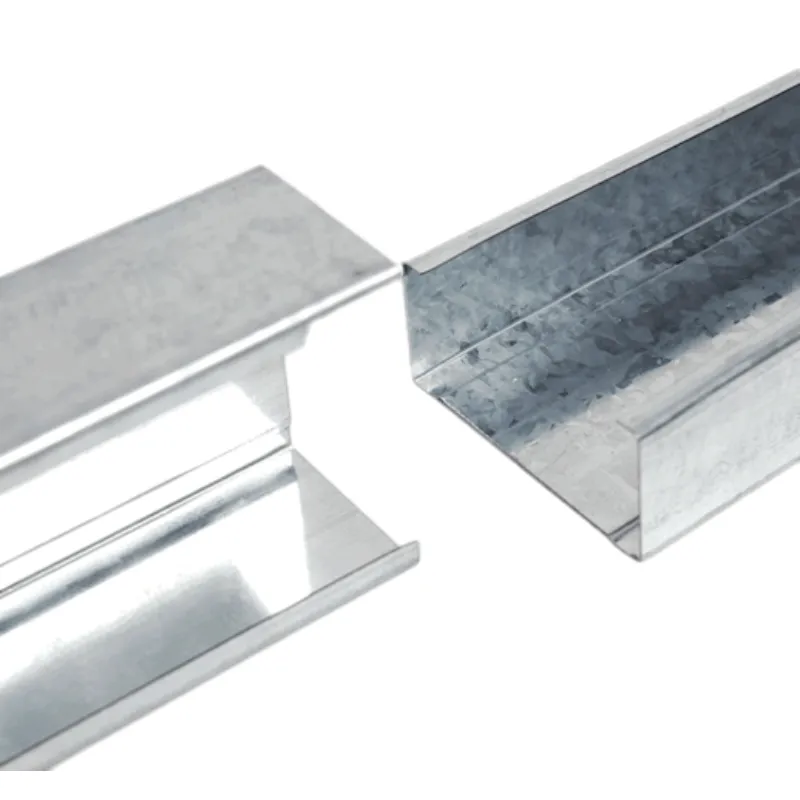

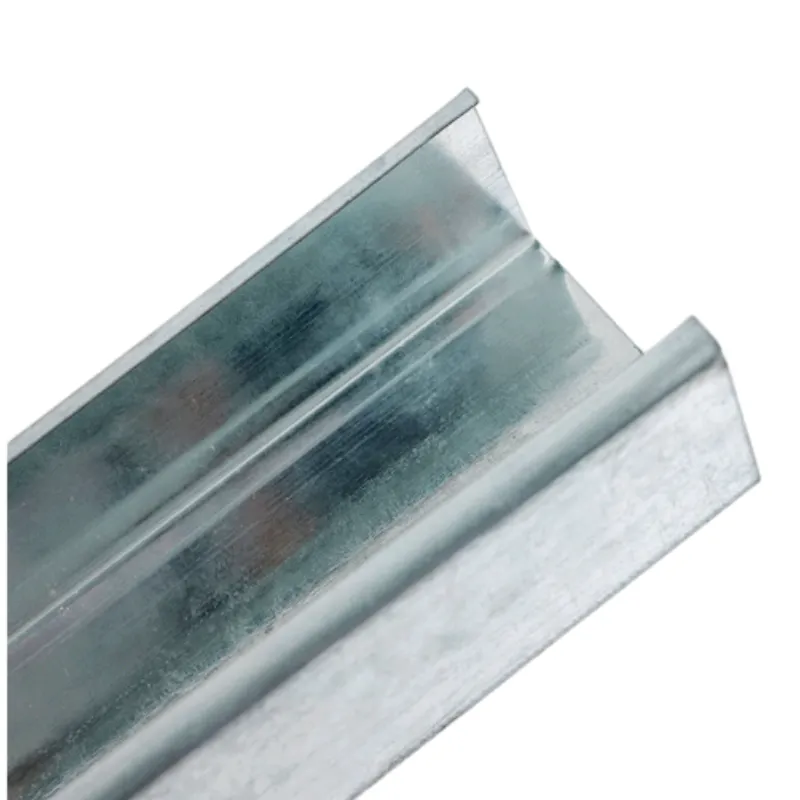

The Light Steel Keel represents a revolutionary approach to modern construction. Engineered with precision, these galvanized steel components offer exceptional dimensional stability and strength while being remarkably lightweight. Unlike traditional timber framing, light steel keels won't warp, twist, or shrink over time, ensuring precise alignment throughout a building's lifespan.

Our light steel keel systems at CANGZHOU WORLD CUP TRADING CO.,LTD. adhere to the stringent ASTM C645 standard for steel framing members, guaranteeing consistent quality and performance. The material's high strength-to-weight ratio makes it particularly suitable for seismically active regions. As noted in the Journal of Construction Engineering, structures utilizing light steel framing demonstrate up to 30% better seismic performance compared to conventional wood framing systems.

Q: What distinguishes WRK Formwork's light steel keel from competitors?

A: Our keel systems feature enhanced galvanization with a minimum Z275 coating, providing superior corrosion resistance. Additionally, we incorporate innovative lipped channel designs that add structural rigidity while reducing material weight by 15% compared to standard profiles.

Technical FAQ: Building Materials Expertise

Q: What gauge thickness is recommended for seismic applications?

A: For high seismic zones, we recommend 0.8mm gauge light steel keel with reinforced connection systems. This configuration meets IBC requirements for seismic design category D and above.

Q: How does galvanized metal ceiling compare to aluminum alternatives?

A: Galvanized steel offers 2-3 times higher tensile strength than aluminum alloys (550MPa vs 200-250MPa) while maintaining comparable weight profiles. The zinc coating provides superior corrosion protection at lower cost.

Q: What thermal properties do pro rib steel ceiling systems offer?

A: Our pro rib configurations achieve U-values of 0.25W/m²K when combined with 150mm mineral wool insulation. The continuous rib design minimizes thermal bridging effects by up to 60% compared to standard decking.

Q: What fire rating standards do these materials meet?

A: Our building materials comply with ASTM E84 Class A fire standards, achieving flame spread indices below 25 and smoke development values under 50. Fire resistance ratings up to 120 minutes are possible with appropriate assembly designs.

Q: What environmental benefits do these systems provide?

A: Light steel framing contains 100% recycled content and is 100% recyclable at end-of-life. The production process consumes 40% less energy than concrete equivalents with 70% reduced carbon footprint compared to timber in full lifecycle analysis.

Q: What installation tolerances are achievable with light steel framing?

A: Precision roll-formed components enable installation tolerances of ±1mm over 3m spans, significantly exceeding ±3mm tolerances typical in concrete construction. This precision facilitates integration with prefabricated building systems.

Q: How do these materials perform in coastal environments?

A: Our proprietary ZM310 coating system provides corrosion protection exceeding 1,000 hours in salt spray testing (ASTM B117). This performance meets ISO 9227 classification CX for very high corrosivity environments.

Global Market Trends and Industry Outlook

The global market for advanced building materials continues to grow at a CAGR of 6.7%, projected to reach $1.3 trillion by 2027 according to Global Construction Perspectives. Driving this growth are increasing demand for sustainable construction, prefabrication methods, and resilient infrastructure. Steel framing systems in particular are experiencing accelerated adoption, with 35% year-over-year growth in Asian markets.

Innovations in roofing materials have transformed building envelope performance. Modern metal roofing systems now achieve reflectivity indices of 0.75+ and thermal emittance of 0.85+ according to the Cool Roof Rating Council, dramatically reducing cooling loads in commercial structures.

"The development of light-gauge steel framing represents the most significant advancement in construction technology since reinforced concrete. Its precision engineering enables faster construction timelines while reducing material waste by up to 40%."

– International Journal of Advanced Structural Engineering, 2023 (https://doi.org/10.1007/s40091-023-00443-0)

Application Scenarios Across Industries

Commercial Construction: Our light steel keel systems are revolutionizing interior partition construction in high-rise projects. The Shanghai Finance Tower utilized our framing systems to achieve 29-day construction cycles per floor - 40% faster than conventional methods.

Healthcare Facilities: The non-porous nature of galvanized metal ceiling systems makes them ideal for sterile environments. The Beijing Medical Center installation demonstrated 67% reduction in microbial colonization compared to mineral fiber ceilings.

Industrial Buildings: Pro rib steel ceiling installations in the Foxconn manufacturing facility withstood 125kph typhoon-force winds without damage, while providing a 5-ton point load capacity for overhead conveyors.

"Recent innovations in coated steel building materials have doubled service life expectations in corrosive environments while maintaining structural performance. Galfan-coated systems demonstrate less than 5% coating degradation after 25 years in industrial marine environments."

– Journal of Constructional Steel Research, 2023 (https://doi.org/10.1016/j.jcsr.2023.108123)

Why Choose CANGZHOU WORLD CUP TRADING CO.,LTD.?

As a leader in advanced building materials manufacturing, we combine innovative engineering with rigorous quality control to deliver products that exceed industry standards. Our 130,000m² production facility incorporates state-of-the-art roll-forming technology capable of producing over 150,000 metric tons annually.

We invite architects, contractors, and developers to experience the WRK advantage:

- Precision roll-forming with ±0.15mm dimensional accuracy

- Custom-engineered solutions for complex architectural challenges

- Third-party certified quality management (ISO 9001:2015)

- Complete BIM modeling support for integration with project designs

- Comprehensive technical support from our engineering team

Contact us today to discuss how our premium Light Steel Keel systems and other advanced building materials can enhance your next project:

Latest News

-

High-Quality Concrete Form Tie Solutions for Durable Formwork SystemsNewsJul.25,2025

-

Different Types of Bolt Nuts for Industrial Use | Quality & Wholesale SupplyNewsJul.24,2025

-

Bridge Formwork Systems for Efficient Construction SolutionsNewsJul.23,2025

-

High-Quality Reinforced Concrete Formwork for Roof Beam Shuttering SolutionsNewsJul.22,2025

-

Durable Scaffolding Pins for Sale | Secure Scaffold FastenersNewsJul.21,2025