This method is efficient for creating uniform,precise parts quickly and in large quantities. WRK produce the Waller involves the following steps:

Material Selection

WRK always chose different standard raw materials based on the required strength and durability of the waller, but normal we used new standard Q235 or Q345 carbon steel, it is always the cost-effective material, both to ensure the stability of stamping, but also to ensure the use of mechanical imperialistically .

Stamping Process

The metal sheet is fed into the stamping machine,where it is pressed into the desired shape.This could be a simple rectangular or more complex profiles depending on the application and molds.

Cutting and Trimming

After the initial stamping,any excess material is cut and trimmed to achieve the final dimensions of the Waller.

Finishing

The waller may undergo further finishing processes such as coating or galvanizing to protect against corrosion and enhance durability.

Buildings Wallers are used in various aspects of construction,particularly in the following ways

Formwork Systems

Wallers provide horizontal support to vertical formwork panels,helping to distribute the weight of wet concrete evenly and ensuring that the concrete retains its intended shape during pouring and curing.

Shoring Systems

In excavation or construction activities,wallers are used to stabilize and reinforce vertical members,preventing lateral movement or collapse by distributing soil pressure or other external forces.

Scaffolding SystemsWalers are placed at different levels in scaffolding to create a rigid framework that can withstand the weight of workers,equipment,and materials,ensuring a safe working environment.

Retaining Walls and Bridges

Wallers are used in the construction of retaining walls and bridges to reinforce and distribute loads,preventing deformation or failure of vertical members.

Temporary Structures

Wallers provide reinforcement and stability to temporary structures such as walls,platforms,or supports during renovation or construction projects.

Tunneling and Excavation

In tunneling and excavation projects,wallers support and strengthen vertical members,distributing lateral forces exerted by the surrounding soil to ensure stability and safety.

In summary,formwork Waller plates are essential in the construction industry for their support and reinforcement capabilities,and they are produced using efficient stamping machines to meet the demands of various construction applications.

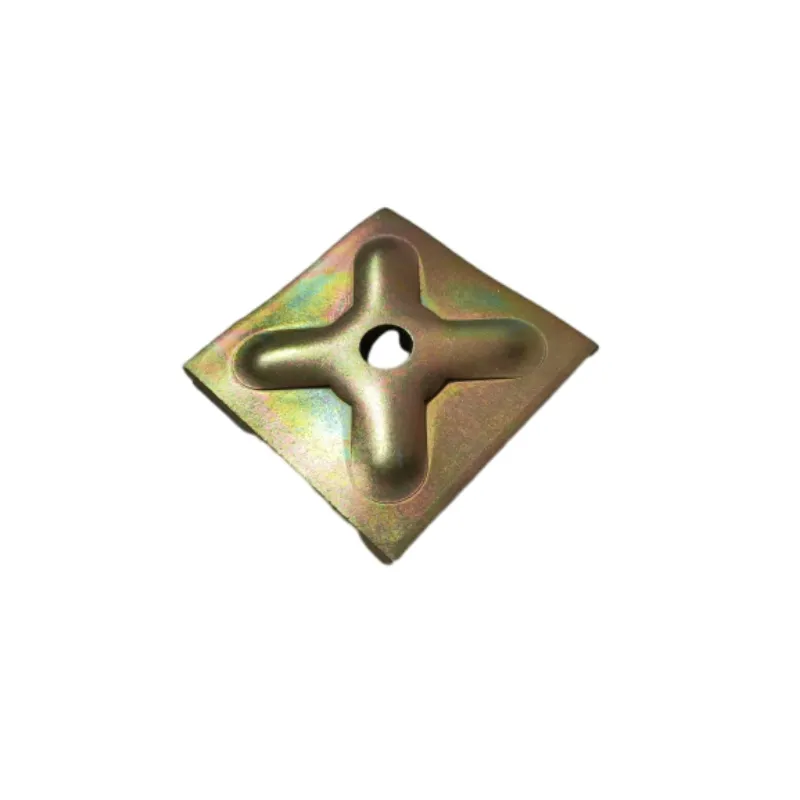

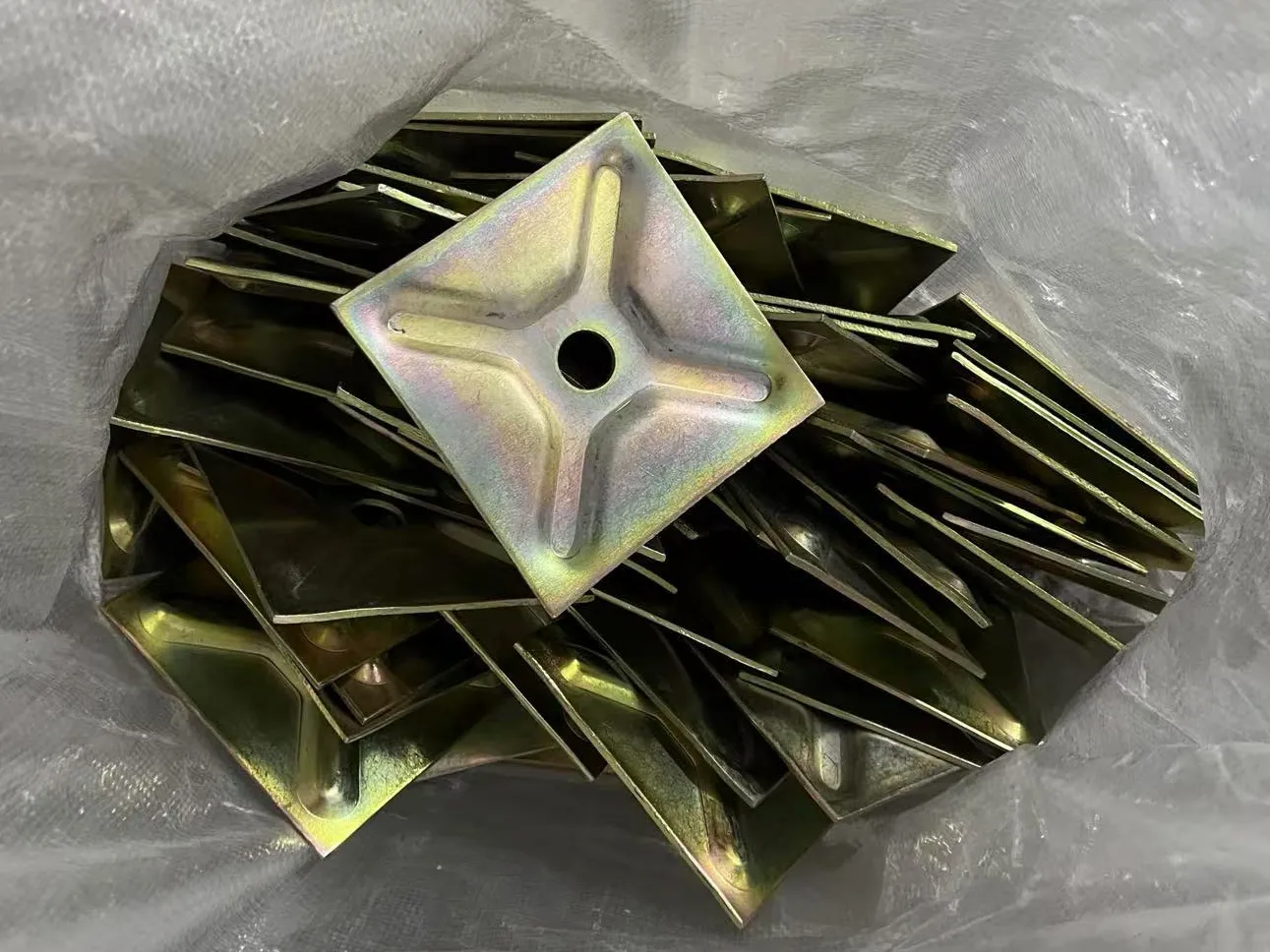

WRK hot types as following:

|

Design |

Plate size |

Used Diameter |

Surface Treatment |

Packages |

|

|

100*100mm |

15/17mm tie rods |

Nature/Yellow galvanized/Sliver galvanized |

Wooden Bags/Wooden Pallets/Wooden Cases |

|

|

120*120mm |

20/22mm tie rods |

||

|

|

100*100mm |

15/17mm tie rods |

||

|

|

115*115mm |

20/22mm tie rods |

||

|

|

90*90mm |

10/12mm tie rods |

||

|

Other OEM designs(please provide your drawings, let us produce for you) |

|

|||

Shipping Map

Write your message here and send it to us

Related News

Products categories