This ensures the desired shape and structure,making combin nuts critical for providing a strong and secure connection between formwork panels and tie rods.

Applications in Construction

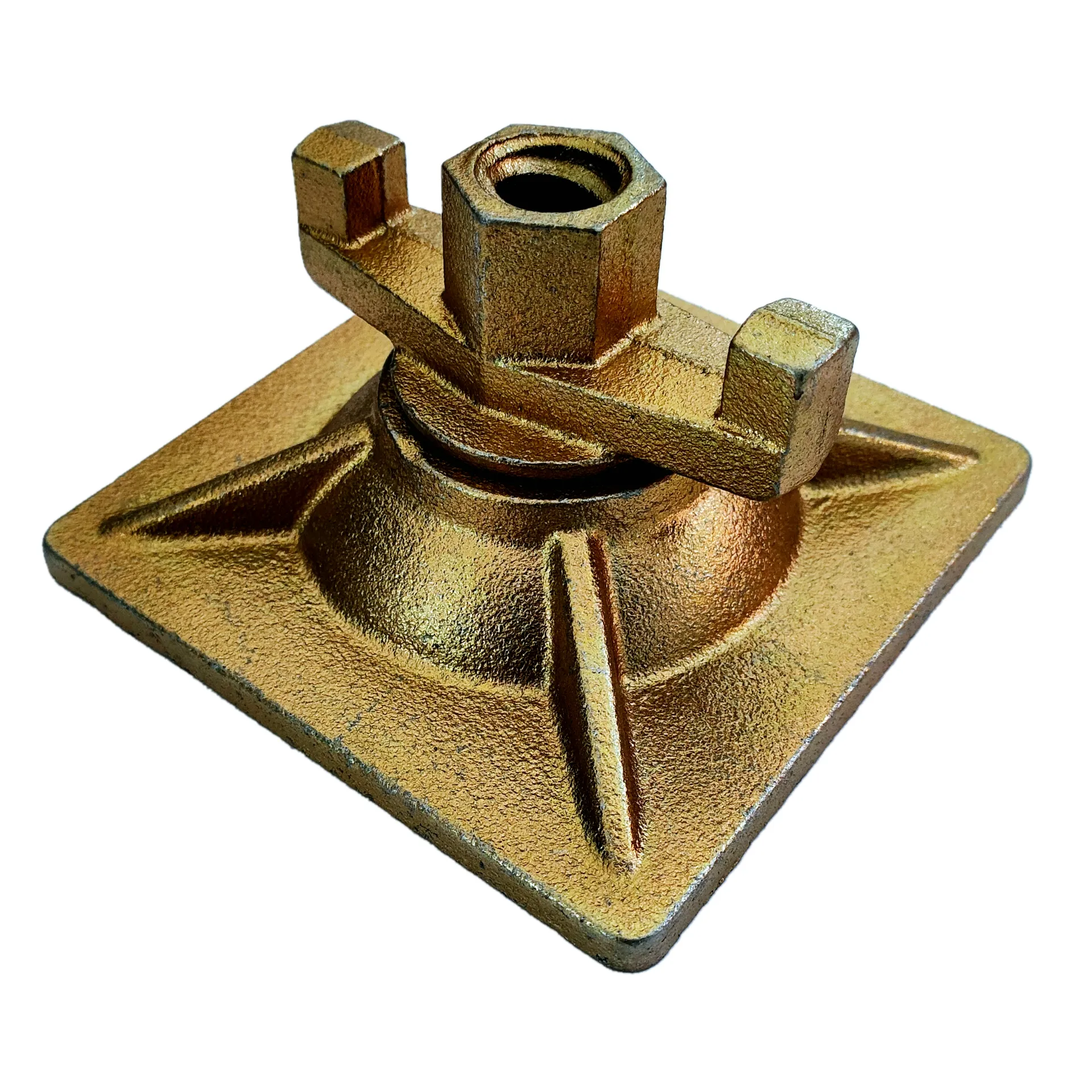

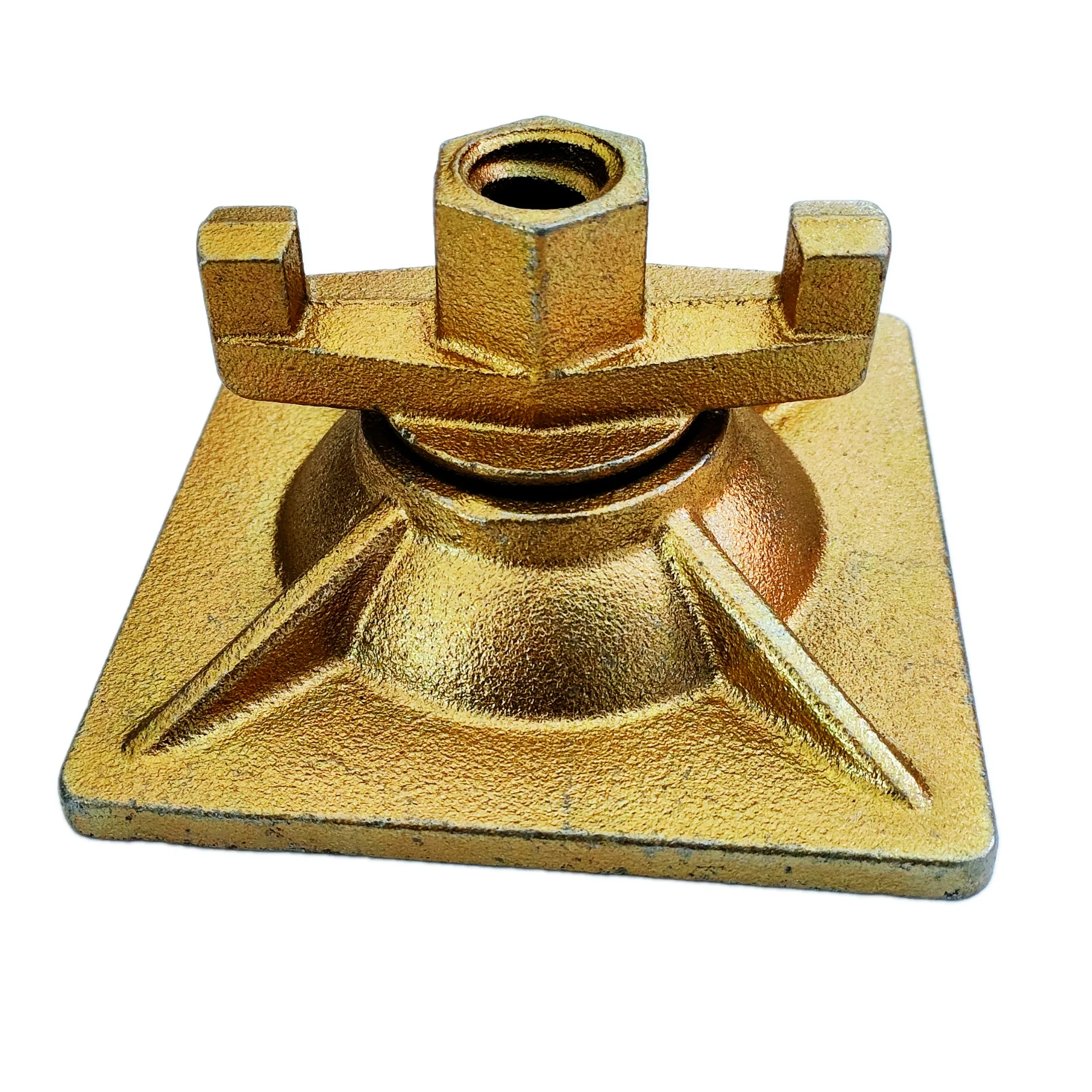

WRK offers types of formwork combin nuts for customer’s different requirements, popular standard sizes as following specifications:

|

Size

|

D15/17*10mm

|

D15/17*10mm

|

D15/17*10mm

|

D15/17*10mm

|

D15/17*10mm

|

D20/22*10mm

|

|

Design

|

|

|

|

|

|

|

|

Base Dia.

|

120*120mm

|

120*120mm

|

120mm

|

120mm

|

140mm

|

90*110mm

|

|

Weight

|

1.10kg

|

1.25kg

|

1.00kg

|

1.10kg

|

1.38kg

|

0.96kg

|

|

Materials

|

Ductile cast iron JIS FCD450

|

|

Surface

|

Nature/Yellow galvanized/Sliver galvanized

|

|

Packages

|

Bags/Pallets/wooden cases

|

|

Loading capacity

|

More than 180KN

|

|

Application

|

Formwork tie rod system

|

|

Related Products

|

Fomwork tie rod, Waller plate, Steel cone, hex nut, rapid clamp etc.

|

|

OEM

|

Customer’s design available

|

Material Selection

To produce these nuts by casting ductile cast iron,the process involves several steps

Casting of Basic Cast Iron ,The first step is to cast basic cast iron with the proper chemical composition,characterized by high graphitization nodulizing ability.This is ensured by an appropriate high content of carbon and silicon. WRK technology department has rich experience of materials to ensure quality reached highest level.

Addition of Nodulizers,such as magnesium,are added to the liquid iron to promote the formation of spheroidal or compacted form of graphite,which is specific to ductile irons.A certain quantity of magnesium is necessary to obtain the graphite in spheroidal or compacted form.

In-Ladle Treatment ,One of the common methods for nodulizing ductile iron is the in-ladle treatment process.Magnesium-ferromagnetic-Si-Mgis placed into a deep pocket at the bottom of the ladle,along with a steel scrap barrier or calcium carbide.This process affects the quality of ductile iron produced,depending on the percentage of magnesium-ferromagnetic used and the nodulizing technique.

Thread Rolling,After the casting process,the nuts are processed with thread rolling,which is a specialized work for ductile iron casting.In the building formwork system, combin nuts work by being typically used in conjunction with formwork tie rods.They secure and tighten formwork panels together,ensuring that the panels can withstand the pressure during concrete pouring and curing.This process is critical for maintaining the shape and structure of the concrete as it sets.To guarantee the quality of the casting iron nuts

ISO Certification ,The foundry should be ISO 9001-certified,which ensures a certain level of quality control and process management.

Quality Control Severe quality control measures should be in place to ensure that the formwork tie nuts meet the required standards and perform as expected in construction projects.

Material Selection Using ductile iron casting JIS FCD450/500,ensures the nuts have the necessary strength and durability for use in construction.

Standard exporting packing ways normal : Wooden cases/Wooden Pallets/Big Woven Bags.

Shipping Map